Description

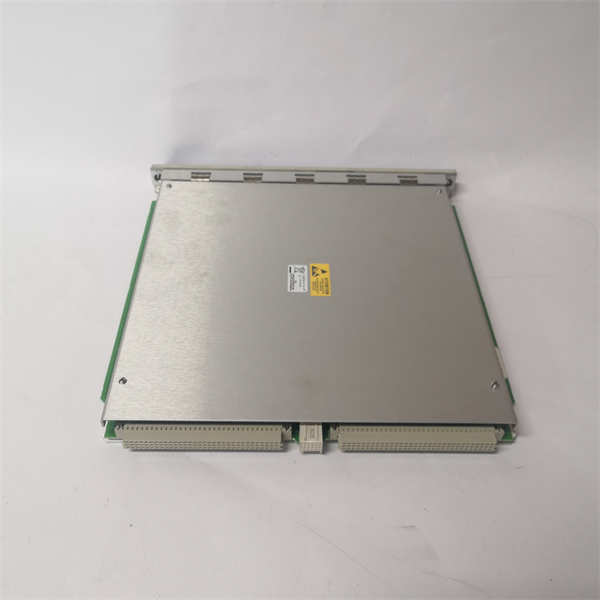

Key Technical Specifications (For Spare Part Verification)

- Product Model: 3500/22M

- Part Number: 138607-01

- Manufacturer: Bently Nevada (Baker Hughes)

- Product Family: 3500 Monitoring System

- Channels: 2 independent relay outputs

- Contact Rating: 2 A @ 30 V DC, resistive load

- Relay Type: Form C (SPDT)

- Response Time: < 10 ms

- Mounting: 3500 chassis backplane (4-slot height)

- Operating Temperature: 0°C to +65°C

- Compliance: CSA, CE, IEC 61010

System Role and Downtime Impact

The 3500/22M relay module is a key actuation component within the Bently Nevada 3500 machinery protection system. It translates alarm and trip signals from monitoring modules (e.g., vibration, speed, or position monitors) into dry contact closures that interface with plant-wide safety systems such as ESD (Emergency Shutdown) or DCS trip logic. In critical rotating equipment—such as steam turbines, centrifugal compressors, or large pumps—this module often serves as the final hardware layer before a mechanical trip is initiated.

Failure or malfunction of the 3500/22M can lead to either a spurious trip (causing unplanned downtime) or, more critically, a failure-to-trip during an actual overspeed or high-vibration event—posing severe safety and asset integrity risks. Because it resides in a centralized 3500 rack, its failure typically affects multiple protection loops simultaneously, potentially compromising the entire machinery train.

Reliability Analysis and Common Failure Modes

Although designed for industrial reliability, the 3500/22M is susceptible to several age-related failure mechanisms after 10–20 years of service. The most prevalent issue is relay contact degradation due to arcing during repeated switching, especially when driving inductive loads without proper suppression. This leads to increased contact resistance, intermittent operation, or welded contacts.

Internal electrolytic capacitors on the logic board also degrade over time, particularly in high-temperature control rooms, causing erratic behavior or complete loss of output. Additionally, the module’s edge connector pins are prone to oxidation or fretting corrosion due to thermal cycling, resulting in intermittent communication with the 3500 backplane.

Design limitations include the lack of built-in self-diagnostics for relay health and no remote indication of contact status—making predictive maintenance challenging.

Recommended preventive actions:

- Perform annual contact resistance testing using a low-resistance ohmmeter

- Inspect for signs of overheating at terminal blocks and relay coils

- Verify correct jumper settings (alarm vs. trip configuration) during routine checks

- Monitor system event logs for unexpected relay state changes

BENTLY NEVADA 3500/22M (138607-01)

Lifecycle Status and Migration Strategy

Bently Nevada has officially discontinued the 3500/22M (138607-01). While some legacy 3500 racks remain in service globally, no new units are manufactured, and factory repair services are no longer available. Spare parts are now sourced exclusively through third-party brokers, with prices often exceeding $2,500 per unit and authenticity concerns rising.

As an interim solution, facilities may use certified refurbished modules or implement external relay duplication (using modern safety relays triggered by 3500 analog or digital outputs)—though this adds complexity and may not meet original SIL requirements.

For long-term reliability, migration to the Bently Nevada 3500/22M Enhanced (if still available under limited support) or, preferably, a full transition to the Bently Nevada Guardian platform is advised. Guardian offers integrated relay diagnostics, cybersecurity features, and native compatibility with modern asset management systems. Migration requires re-engineering the I/O architecture, updating logic solver configurations, and re-validation of protection logic—but delivers improved availability, compliance with IEC 61508/61511, and extended support lifecycle.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: