Description

Key Technical Specifications (For Spare Part Verification)

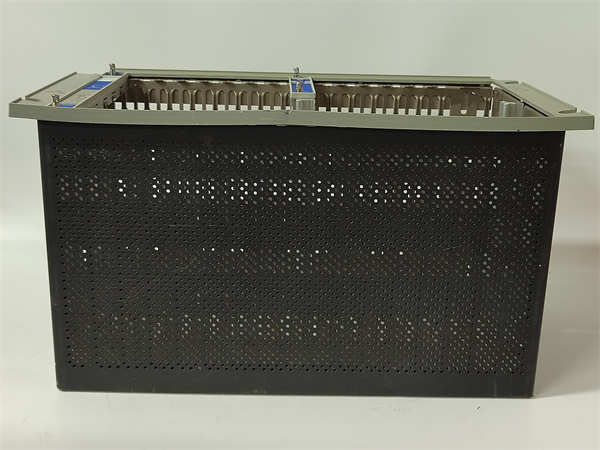

- Product Model: 3500/05

- Full Order Code: 3500/05-01-02-00-00-00-01

- Manufacturer: Bently Nevada

- System Compatibility: Bently Nevada 3500 Machinery Protection System (standard and enhanced racks)

- Communication Interfaces: RS-232/RS-422 (for configuration), and dual redundant RS-485 for Modbus RTU or proprietary protocols

- Redundancy Support: Supports redundant 3500/05 pair configuration for high-availability applications

- Backplane Role: Manages module addressing, power-on sequence, and real-time data aggregation from I/O modules

- Diagnostic Features: Status LEDs for RUN, COMM FAULT, PRIMARY/STANDBY, and module OK

- Mounting: Occupies one full-height slot (typically Slot 1) in 3500 chassis

- Configuration Tool: Requires 3500 Rack Configuration Software (RCS) via serial connection

- Firmware Dependency: Tied to specific RCS versions; mismatch may prevent recognition

System Role and Downtime Impact

The 3500/05 module acts as the central nervous system of the Bently Nevada 3500 rack. It collects vibration, speed, temperature, and other data from I/O modules (e.g., 3500/42, 3500/60) and transmits it to plant control systems, historians, or operator workstations via serial or Modbus protocols. In redundant configurations, it ensures seamless failover between primary and standby units. If the 3500/05 fails—especially in non-redundant setups—the entire rack becomes operationally isolated: alarms may not reach the control room, trip relay status cannot be monitored remotely, and trending data is lost. While local protection logic (e.g., hardwired trips from 3500/53 or 3500/60) may remain functional, the loss of supervisory visibility significantly increases operational risk and complicates troubleshooting during critical events.

Reliability Analysis and Common Failure Modes

Although designed for industrial reliability, the 3500/05 (order code ending in -01) exhibits age-related vulnerabilities typical of early-2000s embedded controllers. The most common failure mode is serial communication IC degradation, leading to intermittent or complete loss of Modbus/RS-485 connectivity—often misdiagnosed as a wiring issue. Firmware corruption after unexpected power cycles can cause boot loops or “unrecognized module” errors in RCS. Additionally, capacitor aging on internal DC-DC converters may result in unstable backplane signaling, causing I/O modules to drop offline intermittently.

A key weakness is its reliance on serial-based configuration; damaged or corroded DB9 connectors, or incorrect baud rate settings, can prevent access during emergencies. Units operated in high-EMI environments (e.g., near VFDs or switchgear) show increased susceptibility to communication glitches due to inadequate shielding in older revisions.

Recommended preventive practices include:

- Performing periodic communication health checks with the host DCS or historian

- Maintaining up-to-date configuration backups in 3500 RCS

- Verifying redundancy switchover behavior during scheduled outages

- Inspecting rear terminal blocks and serial cables for corrosion or looseness

BENTLY 3500-05-01-02-00-00-01

Lifecycle Status and Migration Strategy

Bently Nevada has formally obsoleted this specific variant of the 3500/05 module. While newer 3500/05 revisions exist with improved EMI resilience and firmware stability, the -01-02-00-00-00-01 configuration is no longer manufactured, and official repair services are unavailable. Continued operation increases exposure to extended diagnostic delays and potential non-compliance with modern cybersecurity or data integrity standards.

Short-term mitigation includes:

- Securing multiple tested spares with identical order codes and firmware levels

- Documenting serial protocol settings (baud rate, parity, node ID) and wiring schematics

- Validating full rack restore procedures using a test chassis

For long-term continuity, Bently Nevada supports migration to the current 3500/05 Interface Module (latest revision), which maintains mechanical and electrical compatibility with existing 3500 racks. Replacement typically involves:

- Direct swap without rewiring

- Re-downloading configuration via 3500 RCS

- Updating host system communication drivers if protocol enhancements are present

For facilities integrating with modern asset performance platforms, the 3500 system can be connected to Baker Hughes System 1 or third-party OPC servers to enable secure, Ethernet-based data access—reducing reliance on legacy serial links. While the obsolete 3500/05 cannot be upgraded in place, transitioning to a supported revision restores access to technical support, configuration tools, and spare parts, ensuring reliable machinery protection beyond 2030. A phased, rack-by-rack approach minimizes operational disruption while managing cost and risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: