Description

Technical Specifications (For Spare Part Verification)

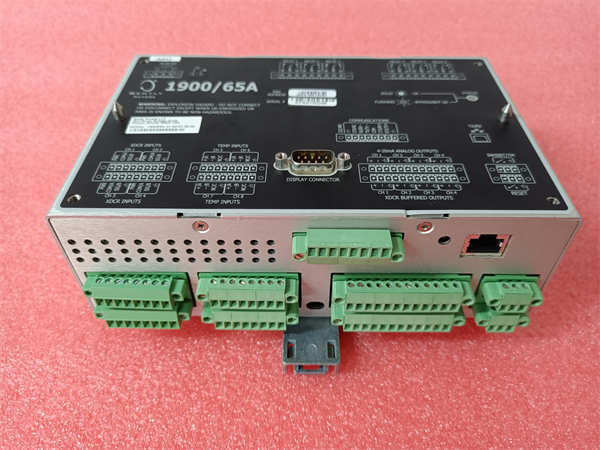

- Product Model: 1900/65A-01-02-01-00-00

- Manufacturer: Bently Nevada

- System Family: 1900 Series Machinery Protection System

- Input Channels: 4 analog channels (accepts Bently proximity probes, velocity sensors, or accelerometers)

- Signal Processing: Real-time RMS, peak, and 0–10 kHz spectral analysis per channel

- Relay Outputs: 8 programmable alarm/trip relays (Form C, 5 A @ 250 VAC)

- Communication Interfaces: RS-232/485 (Modbus RTU), optional Ethernet (requires separate communication module)

- Power Supply: 100–240 VAC, 50/60 Hz (dual power supply option available)

- Mounting: 19-inch rack mount (3U height)

- Compliance: API 670 4th Edition (Machinery Protection Standard)

- Firmware Revision: Must match existing system configuration (e.g., v5.x) for seamless replacement

System Role and Downtime Impact

The Bently Nevada 1900/65A serves as a dedicated machinery protection monitor in critical applications such as gas turbines, centrifugal compressors, and large pumps in oil & gas, power generation, and petrochemical facilities. It continuously evaluates vibration and position data against user-defined alarm and trip thresholds, directly interfacing with plant safety systems to initiate automatic shutdowns when dangerous conditions are detected. Unlike condition monitoring systems used for diagnostics, the 1900/65A is part of the safety instrumented function (SIF)—its failure can have two severe consequences: (1) a dangerous failure where it fails to trip during an actual fault, leading to catastrophic machine destruction; or (2) a safe failure where it issues a false trip, causing an unplanned and costly process shutdown. In either case, the absence of a verified spare introduces unacceptable operational and safety risk.

Reliability Analysis and Common Failure Modes

Despite its rugged design, the 1900/65A exhibits predictable aging patterns common to electronics deployed in industrial environments since the early 2000s. The most frequent failure mode is degradation of the internal power supply modules, particularly in units subjected to continuous high line voltage or thermal stress, resulting in intermittent reboots or complete power loss. Analog input circuitry—especially the front-end signal conditioning for proximity probe channels—is susceptible to damage from electrical transients induced by nearby motor starts or lightning events. Additionally, the internal real-time clock (RTC) battery often depletes after 10–15 years, causing time-stamp corruption in event logs and potential configuration drift.

Key design vulnerabilities include:

- Limited overvoltage protection on sensor inputs (relies on external barriers)

- Non-redundant CPU architecture in base models

- Proprietary firmware tied to specific hardware revisions

Preventive maintenance recommendations:

- Perform annual functional test using Bently’s recommended calibration procedure (simulate 4–20 mA or proximity probe signal)

- Inspect terminal blocks for corrosion or loose connections (torque to 0.6 Nm)

- Verify relay contact resistance (<50 mΩ) and alarm logic via forced test

- Maintain offline backup of full configuration (.cfg file) and firmware image

Bently Nevada 1900/65A-01-02-01-00-00

Lifecycle Status and Migration Strategy

Bently Nevada officially discontinued the 1900/65A series in 2016, with end-of-support declared in 2020. No new units are available from the manufacturer, and remaining inventory exists only through third-party surplus channels—often without validation of calibration or firmware integrity.

As a temporary measure, facilities may:

- Secure 1–2 fully tested spares with matching firmware and I/O configuration

- Install external transient voltage suppression (TVS) devices on all sensor lines

- Implement redundant monitoring using portable data collectors as a backup layer

For long-term compliance and reliability, Bently Nevada recommends migration to the 3500/42M or 3500/44M monitor modules within the 3500 System, or the newer Velomitor® Smart Machine Protection System. The 3500 path requires:

- Replacement of the entire monitor chassis and I/O modules

- Rewiring of sensor and relay connections (pinout differs)

- Reconfiguration of alarm logic in Rack Configuration Software (RCS)

While this represents a capital investment, it restores access to factory support, cybersecurity updates, and alignment with current API 670 5th Edition requirements. A staged migration during planned turnarounds is the accepted industry practice to eliminate obsolescence risk while maintaining machinery protection integrity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: