Description

Key Technical Specifications (Spare Part Verification)

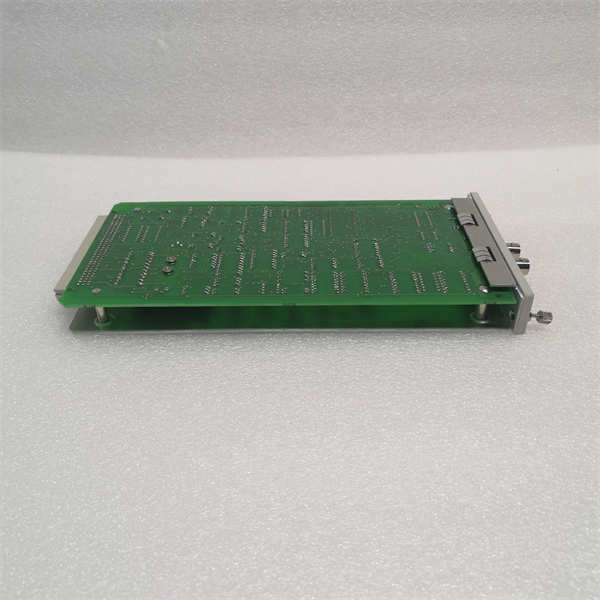

- Product Model: 3500/25

- Manufacturer Part Number: 125792-01

- Manufacturer: Bently Nevada (Baker Hughes)

- Product Family: 3500 Monitoring System

- Input Type: Accepts proximity probe or magnetic pickup (MPU) signals

- Channels: 2 independent Keyphasor inputs (redundant or dual-shaft support)

- Output: TTL-compatible tachometer pulses and buffered analog output (for speed indication)

- Frequency Range: 0.5 Hz to 5 kHz (configurable filtering)

- Mounting: 3500 chassis backplane (1-slot height)

- Operating Temperature: 0°C to +65°C

- Compliance: CSA, CE, IEC 61010, API 670 compliant (as originally supplied)

System Role and Downtime Impact

The 3500/25 module serves as the timing backbone of the Bently Nevada 3500 system. It processes once-per-turn signals from Keyphasor probes to generate precise shaft rotational reference data used by vibration monitors (e.g., 3500/42M) for orbit plots, phase analysis, and runout compensation. Without a valid Keyphasor signal, advanced diagnostics become unreliable, and some protection algorithms may be disabled or operate in degraded mode.

In critical applications such as steam turbines or centrifugal compressors, loss of Keyphasor input can trigger alarms that cascade into automatic trips if redundancy is not implemented. Even in non-trip configurations, the absence of phase data severely limits root-cause analysis during abnormal events, prolonging troubleshooting and increasing mean time to repair (MTTR). The module’s failure rarely causes immediate mechanical damage but significantly degrades operational visibility and protection integrity.

Reliability Analysis and Common Failure Modes

Units in service beyond 10–15 years commonly exhibit failures related to analog front-end circuitry and signal conditioning components. The most frequent issue is loss of signal sensitivity due to aging of the comparator and amplifier stages, particularly when processing low-amplitude MPU signals. This results in missed pulses or erratic speed readings under low-load conditions.

Additional failure modes include:

- Degradation of onboard filtering capacitors, causing noise-induced false triggering or signal dropout

- Oxidation of backplane connector pins, leading to intermittent communication with the 3500 rack controller

- Firmware checksum errors after power cycling, especially if the module was exposed to voltage sags

Design limitations include the lack of per-channel health LEDs and minimal diagnostic feedback—status must be verified through the 3500 Rack Interface or external oscilloscope. The module also lacks surge protection on its field inputs, making it vulnerable to transients from nearby switching events.

Recommended preventive actions:

- Verify signal amplitude and waveform integrity at the module input during outages

- Clean backplane contacts annually using contact enhancer spray

- Ensure proper probe gap setting (typically 1 mm for proximity probes) to maintain strong signal levels

- Avoid routing Keyphasor cables parallel to high-voltage or VFD output lines

BENTLY 3500/25 125792-01

Lifecycle Status and Migration Strategy

Bently Nevada has discontinued the 3500/25 (125792-01). While the broader 3500 platform remains partially supported, this specific variant is no longer manufactured, and factory repair services are unavailable. New units cannot be sourced from the OEM; remaining supply exists only through industrial brokers or decommissioned assets, often at prices exceeding $2,500 with no performance guarantee.

As an interim measure, facilities may:

- Maintain tested spares in controlled storage

- Use external signal conditioners to boost weak probe outputs and reduce module stress

- Cross-wire redundant Keyphasor channels to a single healthy input (if system logic permits)

For long-term sustainability, migration to the 3500/25 Enhanced (if still available under limited support) or integration into the Bently Nevada Guardian platform is advised. Guardian natively supports digital Keyphasor processing via its embedded analytics engine and offers remote diagnostics, cybersecurity features, and seamless data export via OPC UA.

Migration requires re-engineering sensor wiring, updating configuration databases, and re-validating protection logic—but eliminates obsolescence exposure and aligns the asset with modern reliability-centered maintenance practices. A phased approach during planned turnarounds is recommended to minimize operational disruption.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: