Description

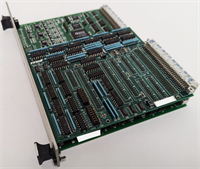

Technical Specifications (For Spare Parts Verification)

- Product Model: DECS-200-2L

- Manufacturer: Basler Electric Company

- System Family: DECS-200 Digital Excitation Control System

- Form Factor: DIN-rail or panel-mounted controller module with removable terminal blocks

- Input Signals: Generator PT (potential transformer) voltage, CT (current transformer) feedback, external reference (optional)

- Output: DC field current command via thyristor gate driver or analog signal

- Regulation Modes: Voltage, VAR, PF, or reactive current control (configurable)

- Communication: RS-485 (Modbus RTU) on later firmware; early units may lack comms

- Power Supply: 24–125 VDC or 120 VAC (field-configurable)

- Protective Functions: Overexcitation limit (OEL), underexcitation limit (UEL), V/Hz limit

- Firmware Version: Fixed or upgradable via EPROM (verify compatibility before replacement)

System Role and Downtime Impact

The DECS-200-2L serves as the core automatic voltage regulator (AVR) in medium-voltage synchronous generator sets—commonly paired with natural gas turbines, steam turbines, or hydro units in industrial or remote power applications. It continuously adjusts rotor field current to maintain stable terminal voltage despite load changes, ensuring compliance with grid codes or internal plant requirements. A failure results in uncontrolled voltage drift, which typically triggers generator protective relays (e.g., 27/59 functions) and forces an immediate trip. In a facility without redundant generation, this leads to total site blackout or costly emergency diesel start-up. Given its role in grid stability, even brief AVR malfunction can cascade into wider electrical disturbances.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, units in service beyond 15–20 years exhibit predictable degradation:

- Power supply capacitor failure: Electrolytic capacitors on the internal DC-DC converter dry out, causing brownouts during transients and erratic regulation.

- Thyristor gate driver degradation: Output stage components fatigue from repeated switching, leading to reduced field current delivery or complete loss of excitation.

- EPROM corruption: Older firmware stored on non-volatile memory can degrade due to heat or radiation, causing boot loops or incorrect control logic.

- Terminal block oxidation: High-current field wiring terminals develop resistance over time, generating localized heating and voltage measurement errors.

A notable vulnerability is the lack of real-time health diagnostics in early -2L units—operators often detect issues only after voltage instability occurs. Additionally, many installations lack proper surge protection on PT inputs, exposing sensitive analog front-ends to lightning-induced transients.

Preventive maintenance recommendations include:

- Performing annual excitation response tests under simulated load steps.

- Inspecting and re-torquing all power and signal terminals.

- Verifying backup power integrity if auxiliary supply is used.

- Storing a known-good spare in climate-controlled conditions with periodic power cycling.

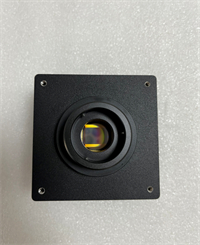

BASLER ELECTRIC DECS-200-2L

Lifecycle Status and Migration Strategy

Basler Electric no longer produces the DECS-200-2L and has shifted support to the DECS-250 and DECS-300 platforms, which offer enhanced cybersecurity, Ethernet connectivity, and improved transient response. While Basler may still offer limited repair services for legacy DECS-200 units, component-level obsolescence makes long-term reliability uncertain.

As an interim solution:

- Confirm exact firmware and hardware revision before installing any spare.

- Use Basler’s BEConfig software (if compatible) to back up existing settings.

- Install external transient voltage suppressors on PT and field leads to extend life.

For sustainable operation, the recommended migration path is upgrading to the DECS-250. This requires:

- Replacing the main controller module (backward-compatible with existing CT/PT wiring in most cases)

- Updating configuration via modern software (BEControl)

- Optionally adding Ethernet/IP or Modbus TCP for SCADA integration

This upgrade preserves existing generator infrastructure while significantly improving reliability, diagnostic capability, and compliance with modern NERC or IEEE standards. Facilities relying on critical onsite generation should prioritize this migration to mitigate unplanned outage risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: