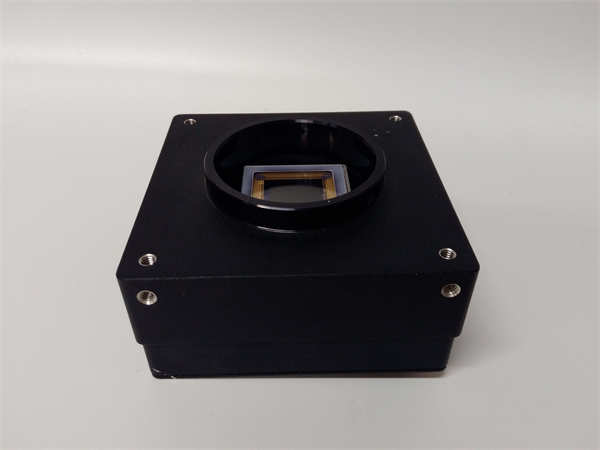

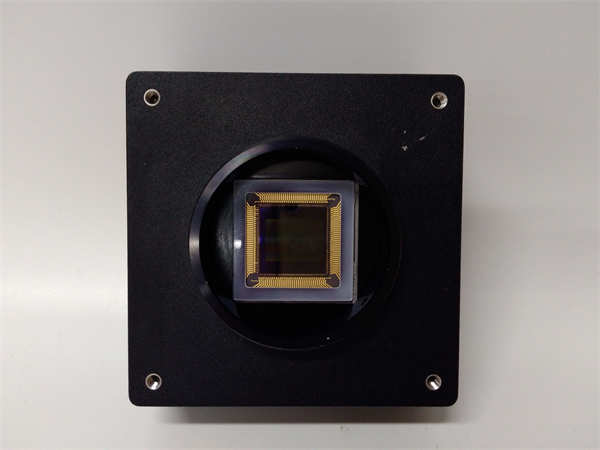

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: A402KC

- Manufacturer: Basler Electric

- Product Family: A400 Series Protective Relays

- Protection Functions:

- 51 (Time Overcurrent – Phase)

- 50G/51G (Instantaneous & Time Ground Fault)

- Input Ratings: 5 A or 1 A CT inputs (field-selectable)

- Operating Voltage: 125 VDC (auxiliary supply)

- Trip Output: Form C electromechanical output contacts (rated 10 A, 250 VAC)

- Settings: Plug-in resistor boards and dial-adjustable time dials (electromechanical setting method)

- Enclosure: Flush-mount ANSI C37.90 panel cutout

- Standards Compliance: IEEE C37.90, ANSI C37.90.1 (surge withstand)

System Role and Downtime Impact

The A402KC is typically deployed as a dedicated protection relay for medium-voltage generators or large motors in industrial plants, hospitals, or municipal power facilities. It operates independently of SCADA or DCS systems, relying on hardwired trip circuits to activate circuit breaker shunt trips during fault conditions. If the relay fails—due to contact welding, setting drift, or internal component degradation—it may either fail to operate during a real fault (risking equipment destruction) or nuisance-trip during normal operation (causing unplanned downtime). In generator applications, loss of reliable ground-fault protection can lead to stator core damage, requiring weeks of repair and costing hundreds of thousands in lost production or emergency generation expenses.

Reliability Analysis and Common Failure Modes

Although built with robust electromechanical and analog solid-state components, the A402KC is now well beyond its design service life (typically 20–25 years). Units still in service are increasingly prone to age-related failures.

Common failure modes include:

- Output contact degradation: Arcing over decades causes pitting or welding, leading to failed trip commands or unintended tripping.

- Resistor board drift: Carbon composition resistors used in time-current characteristic networks change value with age and humidity, altering protection curves.

- Capacitor leakage in timing circuits: Electrolytic capacitors in the induction-disk simulation circuit dry out, causing incorrect time delays.

- Dial mechanism binding: Mechanical wear or dust ingress prevents accurate setting adjustments or causes setting slippage during vibration.

Design weaknesses include:

- No self-diagnostics or event recording—fault analysis requires external oscillography;

- Susceptibility to DC supply ripple, which can affect timing accuracy;

- Settings are not password-protected, risking unauthorized changes.

Preventive maintenance recommendations:

- Perform annual secondary injection testing per IEEE C37.90 to verify pickup and time-delay accuracy;

- Inspect and clean output contacts using non-abrasive methods;

- Verify auxiliary DC supply quality (ripple < 5%);

- Document all physical settings with photographs to detect tampering or drift.

Lifecycle Status and Migration Strategy

Basler Electric ceased production of the A400 series over a decade ago. Official support, calibration services, and spare parts are no longer available. Continued use exposes facilities to regulatory non-compliance (e.g., NFPA 70B recommends replacement of obsolete protection devices) and operational risk.

Interim solutions include:

- Sourcing New Old Stock (NOS) units with full test certification from reputable surplus vendors;

- Engaging third-party relay shops for recalibration and contact refurbishment (though component availability is declining);

- Installing redundant modern relays in parallel for critical assets while retaining the A402KC as a backup.

Basler’s official upgrade path is the BE1-402KC digital relay in the BE1-400 series. This microprocessor-based device offers identical protection functions (51, 50G/51G) but adds:

- Digital setting via front panel or software;

- Event recording, oscillography, and communication (Modbus RTU);

- Self-diagnostics and secure access control.

Migration requires:

- Replacing the panel cutout or using an adapter plate;

- Rewiring CT and trip circuits (contact ratings differ slightly);

- Recalculating and re-entering protection settings in digital format.

While the initial cost is higher than buying a used A402KC, the BE1-402KC eliminates long-term obsolescence risk, reduces maintenance burden, and supports compliance with modern electrical safety standards. For facilities managing multiple legacy relays, a phased replacement program aligned with outage schedules is the most sustainable approach.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: