Description

Technical Specifications (For Spare Part Verification)

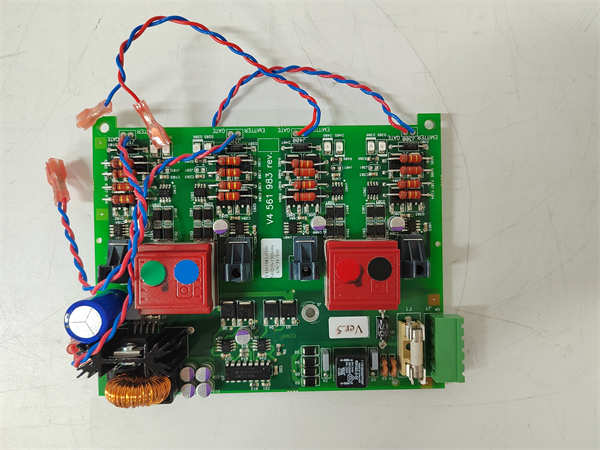

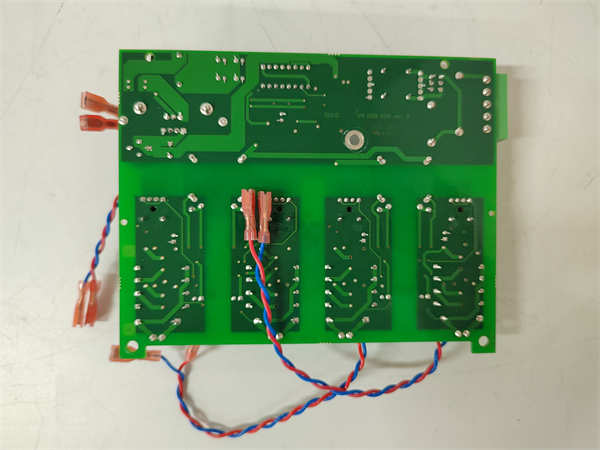

- Product Model: V4561983-0100

- Manufacturer: ALSTOM Power Automation (legacy product line)

- Product Family: P300 / P400 Turbine Control System I/O Modules

- Module Type: Trip logic output interface with electromechanical relays

- Output Configuration: Typically 4–8 safety-rated SPDT (single-pole double-throw) relay contacts

- Contact Rating: 5 A @ 250 V AC / 30 V DC (resistive load), suitable for driving solenoid valves or auxiliary contactors

- Input Logic: 24 V DC signal from P300/P400 controller indicating trip condition

- Redundancy Support: Often deployed in dual-channel or voting configurations for SIL compliance

- Diagnostic Features: Limited or none – primarily hardwired, non-intelligent safety interface

- Mounting: DIN-rail or chassis-mounted within P300/P400 I/O cabinet

- Power Supply: 24 V DC (field-powered or system-powered, depending on installation)

- Compliance: Designed to meet IEC 61508/IEC 61511 requirements for SIL2/SIL3 applications when used in certified architecture

System Role and Downtime Impact

The ALSTOM V4561983-0100 serves as a critical final element in the turbine protection chain within legacy P300 and P400 distributed control systems. It receives trip commands from the main controller and physically opens or closes high-integrity relay contacts to de-energize fuel valves, close steam stop valves, or initiate generator breaker trips. Because this function is often implemented outside the main programmable logic (as a “hardwired safety layer”), its reliability is paramount for regulatory compliance and personnel safety. A failure—such as welded contacts or coil open-circuit—can result in either a dangerous failure (failure to trip during an over-speed event) or a spurious trip (unplanned shutdown). In either case, the unit cannot legally operate until the module is replaced and the entire trip circuit is revalidated. Given its role in safety instrumented functions (SIFs), unavailability of this spare can ground an entire power block for weeks.

Reliability Analysis and Common Failure Modes

The V4561983-0100 relies on electromechanical relays, which are inherently wear-prone due to mechanical cycling and arcing during contact opening under load. The most common failure mode is contact welding—especially when switching inductive loads like solenoid coils without adequate arc suppression—leading to a dangerous “fail-to-danger” state where the turbine cannot be tripped. Conversely, coil burnout or spring fatigue causes “fail-safe” behavior (no trip possible), resulting in operational downtime. Environmental stressors such as high ambient temperature, humidity, and vibration accelerate degradation of both relays and PCB solder joints. Terminal corrosion from sulfur compounds (common in coal-fired plants) increases contact resistance and can cause false open-circuit readings. As preventive maintenance, operators should perform annual manual trip tests that verify both electrical continuity and mechanical actuation of downstream valves. Visual inspection for discoloration, pitting, or carbon tracking on relay contacts is also recommended during outages. Units in storage should be kept in dry, temperature-controlled environments to prevent moisture ingress.

ALSTOM V4561983-0100

Lifecycle Status and Migration Strategy

Following GE’s acquisition of ALSTOM’s power business, the P300/P400 platform—and its associated I/O modules like the V4561983-0100—was officially sunsetted. GE offers no direct replacement, though migration paths exist to the Mark VIe platform. Continuing to operate with this module carries significant risk: spare availability is declining, technical documentation is increasingly difficult to access, and regulatory auditors may question the use of unsupported safety components. Short-term mitigation includes strategic stockpiling of tested spares, implementing external contact supervision circuits to detect welded contacts, and performing more frequent functional safety tests. For long-term compliance, the recommended path is migration to a modern safety-certified system such as GE Mark VIe with SIL3-capable I/O (e.g., V7768-TRP series trip modules). This requires full re-engineering of the protection logic, rewiring of field devices, and recertification of all safety instrumented functions—a capital-intensive but necessary step for plants planning to operate beyond 2030. Interim solutions using third-party safety relays with equivalent ratings are possible but must undergo rigorous functional safety validation to maintain SIL integrity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: