Description

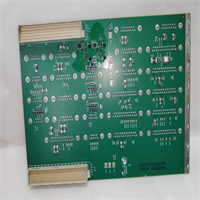

Technical Specifications (For Spare Part Verification)

- Product Model: V4555724-0100

- Manufacturer: ALSTOM Power (France/Germany)

- System Platform: ALSTOM Turbine Control System (TCS), used on steam and gas turbines

- Module Type: Analog input conditioning board (typically 8 or 16 channels)

- Input Signal Range: 4–20 mA DC (standard), with optional support for 0–10 V or thermocouple via external adapters

- Isolation: Channel-to-channel and channel-to-bus isolation (typically >500 V RMS)

- Accuracy: ±0.1% of span (typical at 25°C)

- Backplane Interface: Proprietary ALSTOM TCS bus (parallel digital + power)

- Power Supply: +24 V DC and ±15 V DC derived from system backplane

- Operating Temperature: 0°C to +60°C (requires installation in climate-controlled control cabinet)

- Physical Form: Eurocard format (160 mm x 100 mm), front-panel LED status indicators

System Role and Downtime Impact

The V4555724-0100 serves as a foundational I/O interface in the ALSTOM TCS architecture, converting analog signals from field sensors—such as boiler drum level transmitters, bearing temperature RTDs, or lube oil pressure gauges—into digital data for the main controller. Without accurate analog inputs, the turbine control logic cannot safely regulate speed, load, or protective interlocks. A single failed module can cause multiple measurement points to go invalid, potentially triggering false alarms, automatic runbacks, or emergency shutdowns. In a baseload power station, such an event can result in a forced outage lasting 24–72 hours, with lost revenue and grid penalty costs.

Reliability Analysis and Common Failure Modes

Although designed for industrial use, the V4555724-0100 is now operating well beyond its intended service life (typically 15–20 years). Common failure mechanisms include:

- Input circuit degradation: Precision resistors and op-amps in the signal conditioning path drift over time due to thermal stress, causing measurement offsets that exceed calibration tolerance.

- Isolation barrier breakdown: The optocouplers or isolation amplifiers degrade after prolonged exposure to high common-mode voltages, leading to ground loops or signal noise.

- Power supply capacitor failure: Onboard tantalum or electrolytic capacitors on the ±15 V rails dry out or short, causing channel dropout or complete module lockup.

- Connector corrosion: The rear DIN 41612 backplane connector pins oxidize in humid environments, resulting in intermittent communication with the controller.

Design weaknesses include lack of hot-swap capability and minimal self-diagnostics—most faults are only detected when process values become erratic. For preventive maintenance, site engineers should:

- Perform annual loop calibration checks using a certified mA source

- Inspect module seating and backplane contact integrity during scheduled outages

- Store spares in static-shielded, climate-controlled environments

- Monitor for unexplained process drift as an early indicator of module aging

ALSTOM V4555724-0100

Lifecycle Status and Migration Strategy

ALSTOM ceased production of the V4555724-0100 following its integration into GE, and the entire TCS platform is now classified as legacy. GE no longer provides repair services or firmware updates, and technical documentation is restricted. Continued operation carries mounting risk: functional spares are scarce, and counterfeit or untested units increasingly appear in the gray market.

Short-term mitigation options include:

- Procuring pre-tested, burn-in-verified modules from specialized industrial automation suppliers

- Implementing redundant measurement paths where feasible (e.g., dual transmitters on critical loops)

- Performing board-level rework (capacitor replacement, conformal coating renewal) through qualified third parties

For long-term reliability, GE recommends migrating to the Mark VIe control platform. This transition involves replacing the TCS chassis, I/O modules, operator workstation, and re-engineering the control application. While requiring significant investment, the upgrade delivers modern cybersecurity compliance, enhanced diagnostics, remote access capabilities, and a supported lifecycle through 2040+. For plants with remaining economic life, this migration is the only sustainable path forward.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: