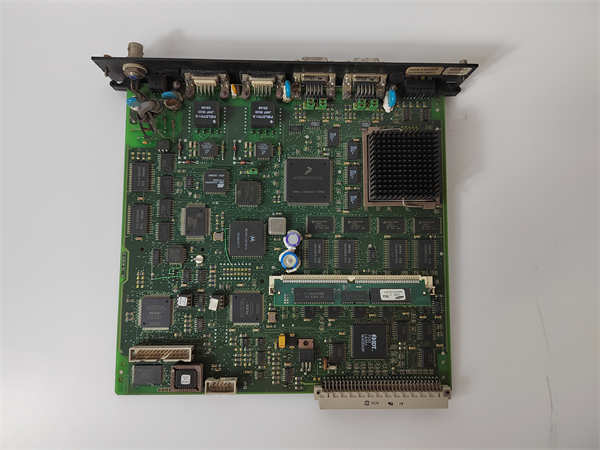

Description

Key Technical Specifications (For Spare Verification)

- Product Model: UT150

- Manufacturer: ALSTOM Power (legacy)

- System Type: Electro-hydraulic turbine control and protection system

- Architecture: Centralized control cabinet with analog/digital I/O, relay logic, and dedicated speed governors

- Control Functions: Speed regulation, load control, ramp/soak sequencing, synchronization, trip logic (e.g., high vibration, low lube oil pressure)

- I/O Types: Hardwired 4–20 mA, RTD, proximity probe (bently-style), discrete inputs/outputs

- Redundancy: Limited—typically single-channel with mechanical backup overspeed trips

- Operator Interface: Local pushbuttons, selector switches, and analog meters; optional remote HMI via serial link

- Communication: Proprietary serial protocols (e.g., Modbus RTU in later versions); no native Ethernet

System Role and Downtime Impact

The ALSTOM UT150 is a mission-critical control system in power plants, cogeneration facilities, and industrial sites relying on steam or combustion turbines for mechanical drive or electricity generation. It directly governs turbine speed during startup, synchronizes with the grid, maintains load demand, and executes rapid shutdowns upon detection of unsafe conditions (e.g., bearing failure, loss of lubrication).

Failure of the UT150—whether due to power supply collapse, I/O card fault, or logic controller malfunction—can result in:

- Uncontrolled turbine acceleration (if overspeed protection fails)

- Inability to start or load the unit, causing energy shortfalls

- Spurious trips, leading to lost revenue and thermal stress on equipment

Because the UT150 often lacks modern redundancy or remote diagnostics, troubleshooting can take days, especially when original documentation or trained personnel are unavailable. In regulated environments, prolonged outages may trigger compliance reporting or penalties.

Reliability Analysis and Common Failure Points

The UT150, typically installed in the 1980s–1990s, exhibits predictable aging issues:

- Electrolytic capacitor degradation: In power supplies and analog signal conditioners, causing voltage droop or noise-induced false trips.

- Relay contact welding or oxidation: Mechanical relays used in trip circuits may fail safe (open) or dangerous (stuck closed).

- Backplane connector fatigue: Repeated thermal cycling loosens DIN or edge connectors, creating intermittent signals.

- Obsolete semiconductor obsolescence: Custom ASICs or early microcontrollers are no longer replaceable; firmware cannot be recovered without original PROMs.

- Hydraulic interface drift: Analog servo-valve drivers lose calibration, affecting throttle response accuracy.

A major vulnerability is the tight coupling between protection and control functions—a fault in the governor section can inadvertently disable trip logic, violating safety integrity principles. To mitigate risk, operators should:

- Perform annual functional tests of all trip paths (e.g., simulate low oil pressure)

- Maintain calibrated spare cards in dry, temperature-controlled storage

- Document wiring and jumper settings before any maintenance

- Install external vibration and speed monitoring as independent oversight

ALSTOM UT150

Lifecycle Status and Migration Strategy

ALSTOM’s power automation business has undergone multiple ownership changes (GE, then formation of GE Steam Power, and partial divestitures). The UT150 is no longer supported by any OEM, with no official repair services, software tools, or replacement parts available.

Short-term options include:

- Engaging specialized third-party firms that reverse-engineer and refurbish UT150 modules

- Implementing “black box” emulation using programmable logic controllers (PLCs) to replicate I/O behavior

- Installing parallel protection systems (e.g., Bently Nevada 3500 or Woodward ProTech) for critical trip functions

Long-term, the only sustainable solution is full control system modernization. Leading approaches include:

- Replacement with GE’s Mark VIe* (for gas turbines) or Steam Turbine Control Retrofit (STCR) solutions

- Migration to open-platform systems like Emerson Ovation, Siemens T3000, or Rockwell Automation PlantPAx with turbine-specific function blocks

- Integration of digital twin models for predictive performance optimization

Such upgrades restore cybersecurity, improve diagnostic coverage, enable remote operation, and extend turbine life by 20+ years—making them essential for asset owners committed to reliability and regulatory compliance in the 2030s and beyond.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: