Description

Technical Specifications (For Spare Parts Verification)

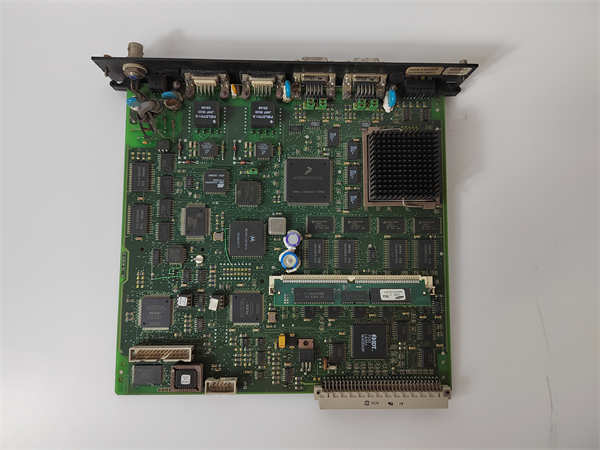

- Product Model: UT150-1

- Manufacturer: ALSTOM

- Protection Functions: Definite/time-inverse overcurrent (phase & earth), instantaneous overcurrent

- Input Ratings: 1 A or 5 A CT secondary (selectable via internal links)

- Operating Voltage: 24–250 V DC or 110/230 V AC (auxiliary supply, model-dependent)

- Trip Output: 1 x normally open (NO) and 1 x normally closed (NC) electromechanical contact

- Setting Method: Plug-in modules with dial-adjustable time/current curves (IEC/IEEE standards)

- Enclosure: Flush-mount metal case, typically 160 x 160 mm front panel

- Standards Compliance: IEC 60255 (legacy editions), EN 50170

- Key Identifier: Label on front or side plate showing “UT150-1”, serial number, and auxiliary voltage code

System Role and Downtime Impact

The UT150-1 is typically installed in medium-voltage switchgear panels at industrial plants, water utilities, and older distribution substations, serving as the frontline protection for outgoing feeders or large motors. It operates independently of SCADA—relying on electromechanical or early solid-state logic to detect overloads and short circuits. If this relay fails to operate during a downstream fault, it can lead to equipment damage, fire risk, or cascading outages. Conversely, a spurious trip due to aging components can cause unplanned process shutdowns. In facilities without modern backup protection schemes, the UT150-1 remains a single point of failure with direct safety and operational consequences.

Reliability Analysis and Common Failure Modes

Although robustly built, the UT150-1 is now decades beyond its design life. Common failure modes include: mechanical wear in the induction disc mechanism (leading to timing drift), oxidation of plug-in setting modules causing incorrect pickup values, and degradation of internal wiring insulation resulting in intermittent operation. Units with solid-state variants may suffer from capacitor drying or semiconductor leakage. A critical vulnerability is the reliance on physical dials and jumpers—settings can shift due to vibration or accidental tampering, and there is no event logging to trace misoperation.

Preventive maintenance should include annual functional testing using a primary or secondary injection test set to verify pickup accuracy and operating time against original curves. Inspect plug-in modules for corrosion, clean contact surfaces, and secure all terminal screws. Where possible, install external sealant on setting dials to prevent unauthorized changes. Given the lack of self-diagnostics, scheduled replacement—even if the unit appears functional—is strongly advised in critical applications.

ALSTOM UT150-1

Lifecycle Status and Migration Strategy

The UT150-1 has been obsolete for more than 15 years, with GE Grid Solutions offering no support, spare parts, or calibration services. Continued use exposes operators to increasing risk of non-compliance with modern protection coordination standards and difficulty sourcing verified replacements.

As a short-term measure, some specialized vendors offer refurbished units with recalibration certificates, but long-term reliability remains uncertain. Maintaining a small inventory of tested spares is prudent for essential sites.

The recommended migration path is replacement with a modern numerical relay such as the GE Multilin™ UR series (e.g., L90, F650) or MiCOM P142/P143 (Schneider Electric). These provide IEC 61850 communication, oscillography, sequence-of-events recording, and remote setting management—features absent in the UT150-1. Migration typically involves minimal rewiring (retaining existing CTs and trip coils) but requires re-engineering of protection settings and integration into substation automation systems. Early planning allows phased replacement during scheduled outages, minimizing disruption while significantly enhancing grid resilience and compliance.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: