Description

Key Technical Specifications (For Spare Parts Verification)

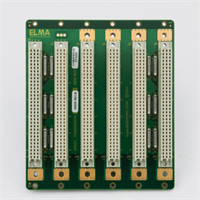

- Product Model: LE109A

- Manufacturer: ALSTOM (Alstom Grid)

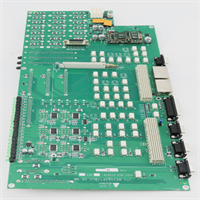

- System Family: Likely part of the L90/L85/LE-series protection architecture used in early digital substation systems

- Module Type: Digital I/O or analog input interface unit (exact function varies by system configuration)

- Mounting: Proprietary rack or chassis slot within Alstom protection panel

- Power Supply: Typically ±12 V / +5 V DC via backplane

- Communication: Proprietary serial bus or parallel interface to main CPU module (e.g., LE100 series controller)

- Input/Output Capacity: Varies—may support contact inputs, RTD signals, or mA-level analog inputs depending on variant

- Diagnostic Indicators: Basic LEDs for power and activity (if equipped)

- Firmware Dependency: Hard-coded logic; hardware revision must match system firmware version

- Environmental Rating: Designed for indoor substation or control room use (IEC 60255 compliant at time of manufacture)

System Role and Downtime Impact

The LE109A functions as a peripheral interface within Alstom’s legacy protection schemes for thermal power plants, hydro stations, or transmission substations. It typically gathers status from breakers, disconnect switches, temperature sensors, or auxiliary relays and forwards this data to the central protection processor. In some configurations, it may also drive trip coils or alarm outputs. A failure can result in loss of visibility into critical equipment status, delayed fault response, or—in worst cases—inability to initiate a protective trip during an internal fault. Given its role in safety-critical infrastructure, such a failure may necessitate derating of generation units or manual override procedures, increasing operational risk and regulatory exposure.

Reliability Analysis and Common Failure Modes

As a product from the 1990s–early 2000s, the LE109A is prone to several aging-related issues:

- Electrolytic capacitor failure in onboard power regulation circuits, causing intermittent resets or complete loss of function.

- Optocoupler degradation in digital input channels, leading to false “open” or “closed” indications from field devices.

- Backplane connector corrosion or mechanical wear, resulting in communication dropouts between the LE109A and the main controller.

- Latch-up or ESD damage on CMOS logic ICs due to inadequate grounding or switching transients in high-energy environments.

A significant limitation is the absence of standardized diagnostics or remote health monitoring. Fault isolation often requires substitution with a known-good module—a challenge when spares are scarce. Additionally, the module contains no user-replaceable components, and its proprietary form factor prevents direct third-party alternatives.

Preventive maintenance should include: annual inspection for capacitor bulging or discoloration, cleaning of backplane contacts, verifying grounding integrity of the protection panel, and maintaining offline backups of system configuration and wiring diagrams.

ALSTOM LE109A

Lifecycle Status and Migration Strategy

Following Alstom’s exit from the grid business and its acquisition by GE (now GE Vernova), the LE109A and associated platforms have been formally discontinued. No new units are produced, and technical support is restricted to legacy service contracts with limited scope. Continued operation relies on dwindling spare inventories, increasing vulnerability to extended outages.

Short-term mitigation includes securing tested modules from retired installations, engaging specialized repair firms for board-level rework (e.g., capacitor replacement, reflow soldering), and implementing external monitoring to detect signal anomalies.

For long-term resilience, migration to a modern protection platform—such as GE’s UR series (e.g., G60, T60) or Multilin™ 8 Series—is strongly advised. This transition involves replacing the entire I/O and control architecture, re-engineering protection logic, and revalidating coordination studies—but delivers benefits including IEC 61850 compliance, cybersecurity hardening, remote diagnostics, and ongoing vendor support, effectively eliminating dependency on obsolete hardware like the LE109A.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: