Description

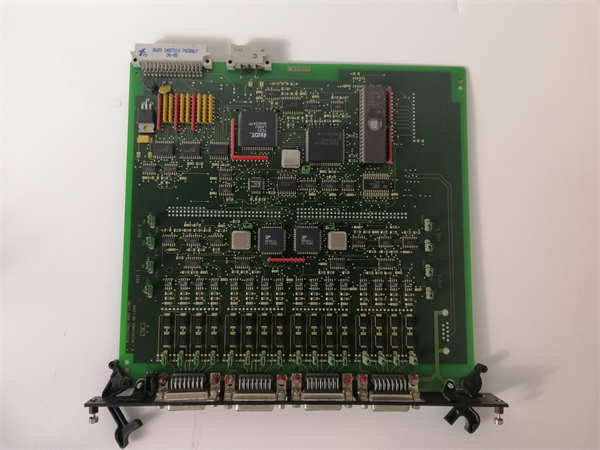

Key Technical Specifications (For Spare Verification)

- Product Model: IR139-1

- Manufacturer: ALSTOM Power Automation (legacy)

- System Integration: Typically mounted in ALSTOM turbine control cabinets (e.g., UT series) alongside speed governors and I/O modules

- Relay Type: Electromechanical or solid-state relays configured in a de-energize-to-trip (fail-safe) architecture

- Input Signals: Hardwired discrete signals from protection sensors (e.g., Bently proximity probes, pressure switches, speed pickups)

- Output Contacts: Form C (SPDT) or Form A (NO) contacts rated for 24–125 VDC/VAC, suitable for driving trip solenoids or interposing relays

- Redundancy: May support dual-channel or voting logic depending on system configuration

- Status Indication: Local LEDs for power, relay status, and fault conditions (varies by revision)

- Mounting: DIN rail or panel-mounted within control enclosure

- Compliance: Designed to meet pre-IEC 61508 safety standards; commonly used in API 612/670-compliant turbine installations

System Role and Downtime Impact

The IR139-1 serves as a last line of defense in ALSTOM turbine protection schemes. Unlike software-based trips, it often implements direct hardwired logic—ensuring that even if the main controller fails, a physical overspeed or low-oil-pressure condition will still trigger a mechanical shutdown. This makes it a safety-critical component in power generation, petrochemical, and industrial drive applications.

Failure modes carry severe consequences:

- Stuck-energized relay: Prevents turbine trip during a real fault → risk of catastrophic overspeed, equipment destruction, or personnel injury

- False de-energization: Causes spurious turbine trip → unplanned outage, thermal stress, lost revenue

Because the IR139-1 is typically not redundant and deeply embedded in proprietary wiring architectures, replacement requires exact functional matching. In many plants, no spare exists—or the spare lacks test documentation—making recovery from failure highly disruptive.

Reliability Analysis and Common Failure Points

Despite its robust design, the IR139-1 is vulnerable to age-related degradation:

- Relay contact welding: Repeated high-current switching (e.g., into inductive solenoid loads) can fuse contacts closed—a dangerous failure mode that disables trip capability.

- Coil burnout or driver transistor failure: Prevents relay energization during normal operation, leading to nuisance trips.

- PCB trace corrosion or solder joint fatigue: Caused by humidity, thermal cycling, or hydrogen exposure in generator environments.

- Capacitor/resistor drift in timing or filtering circuits: Alters response characteristics, potentially delaying trip activation.

A key limitation is the lack of self-diagnostics or remote health monitoring. Most faults are only discovered during functional testing or after a process incident. To reduce risk, operators should:

- Conduct annual manual trip tests using simulated sensor inputs

- Inspect relays for signs of arcing, discoloration, or mechanical binding

- Verify coil resistance and contact continuity with calibrated multimeters

- Maintain detailed as-built drawings of trip logic wiring

ALSTOM IR139-1

Lifecycle Status and Migration Strategy

ALSTOM no longer supports the IR139-1. GE (which acquired ALSTOM’s power business in 2015) does not offer direct replacements, and original engineering documentation is often inaccessible. Continued reliance on this module poses significant safety integrity and regulatory compliance risks, especially under modern functional safety frameworks (e.g., IEC 61511).

Short-Term Mitigations:

- Source and functionally test used units through specialized industrial automation resellers

- Implement external watchdog layers, such as a standalone overspeed protection system (e.g., Bently Nevada 3500/53 or Woodward ProTech 2T)

- Create a “trip validation” procedure using portable test simulators during outages

Long-Term Migration Path:

The recommended approach is full turbine control system modernization, which includes replacing legacy trip logic with certified safety PLCs or dedicated protection platforms:

- Woodward MicroNet Plus or ProTech GII: SIL 3-certified turbine protection with modular I/O

- Bently Nevada 3500/94 + 3500/53: Integrated vibration and speed-based trip solution

- Siemens S7-400F or Rockwell GuardLogix: For integrated control and safety in combined-cycle or cogeneration plants

These systems provide:

- Full diagnostic coverage and event logging

- Compliance with IEC 61508/61511

- Remote access and cybersecurity features

- Decades of future support

While capital-intensive, such upgrades eliminate single-point hardware obsolescence risks and align aging turbine assets with contemporary operational and safety standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: