Description

Key Technical Specifications (For Spare Verification)

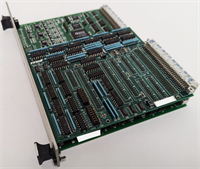

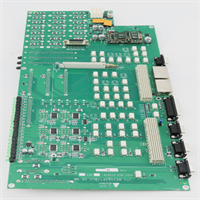

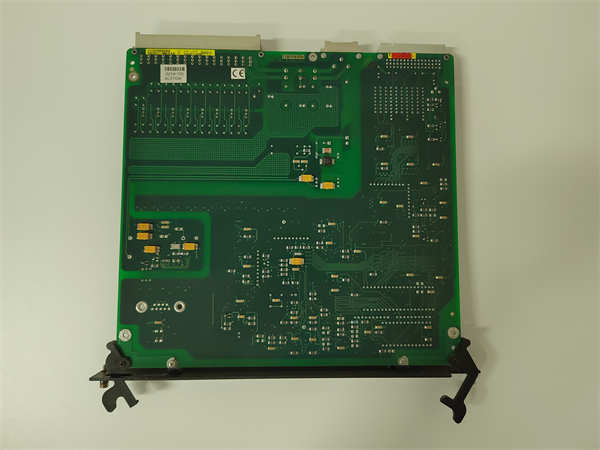

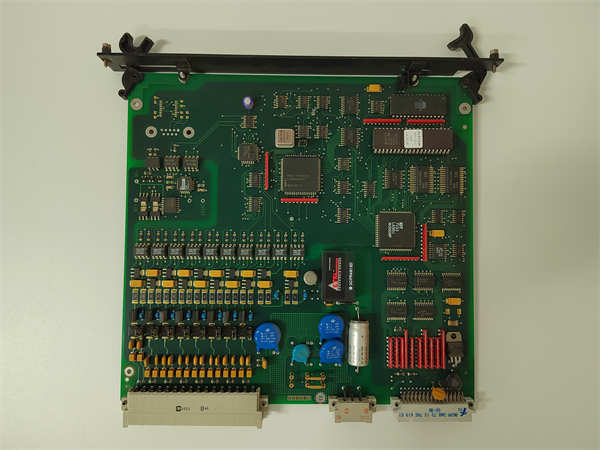

- Product Model: AH116-2

- Manufacturer: ALSTOM Power Automation (legacy product line)

- System Integration: Installed in ALSTOM turbine control cabinets as part of the I/O subsystem for UT-series controllers

- Input Channels: Typically 4 to 8 isolated analog inputs (exact count varies by revision)

- Input Types: 4–20 mA current loops (most common), ±10 VDC, or passive RTD/mV (depending on jumper or DIP switch configuration)

- Isolation: Galvanic isolation between field side and controller side (typically 500–1000 VDC)

- Output Interface: Conditioned signals routed to backplane or terminal blocks for connection to speed governors, sequencers, or trip logic

- Power Supply: ±15 VDC and/or +24 VDC from system power rails

- Status Indicators: May include power OK LED; no per-channel diagnostics

- Form Factor: DIN rail-mountable or rack-mounted PCB with removable terminal blocks

System Role and Downtime Impact

The AH116-2 is a foundational component in the analog signal chain of legacy ALSTOM turbine control systems. It interfaces directly with critical sensors such as lube oil pressure transmitters, bearing temperature RTDs, steam pressure gauges, and vibration probes. Accurate signal conditioning by this module is essential for:

- Stable speed and load control

- Reliable alarm annunciation

- Correct activation of emergency trips (e.g., low oil pressure shutdown)

Failure or drift in the AH116-2 can lead to erroneous process readings, causing:

- Unplanned turbine trips due to false alarms

- Undetected degradation of mechanical conditions (e.g., rising bearing temperature masked by offset error)

- Poor control performance, increasing wear or reducing efficiency

Reliability Analysis and Common Failure Points

Despite industrial-grade construction, the AH116-2 is prone to several age-related failure modes:

- Operational amplifier (op-amp) drift: Causes gain or offset errors in signal scaling—particularly problematic for low-level inputs like RTDs.

- Isolation barrier breakdown: Compromises safety and introduces ground loops, leading to noise-induced instability.

- Electrolytic capacitor aging: In power filtering or reference circuits, resulting in ripple or unstable output.

- Terminal block corrosion or cold solder joints: Creates intermittent connections, manifesting as sporadic signal dropouts.

- Jumper/DIP switch oxidation: Leads to incorrect range selection (e.g., 4–20 mA interpreted as 0–10 V), causing large measurement errors.

A major limitation is the lack of self-diagnostics or digital communication—faults are only detectable through external validation (e.g., HART communicator or calibrated simulator). To mitigate risk, maintenance teams should:

- Perform annual loop calibration using precision current/voltage sources

- Inspect PCBs for bulging capacitors or discolored components

- Clean and reseat terminal blocks during outages

- Maintain records of as-found/as-left calibration data

ALSTOM AH116-2

Lifecycle Status and Migration Strategy

ALSTOM no longer supports the AH116-2. Following GE’s acquisition of ALSTOM Power in 2015—and subsequent business restructurings—official documentation, repair services, and spare parts have been discontinued. Continued use carries significant operational and compliance risks, especially in regulated power generation environments.

Short-Term Mitigations:

- Acquire and functionally test used modules from specialized industrial surplus vendors

- Implement external signal validation using portable calibrators during routine rounds

- Stock critical spares in climate-controlled storage with periodic power-cycling

Long-Term Migration Path:

The sustainable solution is full I/O modernization as part of a broader turbine control system upgrade. Recommended approaches include:

- Replace with universal analog input modules from platforms like:

- Emerson DeltaV CHARMs

- Siemens ET 200SP AI modules

- Rockwell Automation 1756-IF16H (for high-density applications)

- Integrate with a modern turbine control retrofit (e.g., GE Steam Turbine Control Retrofit, Woodward MicroNet Plus, or Siemens T3000)

- Adopt HART or Foundation Fieldbus transmitters to enable digital diagnostics and reduce analog signal chain complexity

These upgrades provide:

- Improved accuracy and noise immunity

- Remote diagnostics and predictive maintenance

- Compliance with cybersecurity standards (e.g., NERC CIP, IEC 62443)

- Decades of vendor support

While requiring engineering investment, migrating away from obsolete modules like the AH116-2 eliminates single-point failure risks and ensures reliable, safe operation of critical rotating assets well into the future.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: