Description

Key Technical Specifications (For Spare Part Verification)

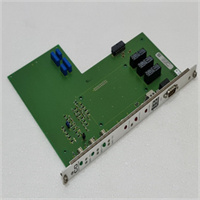

- Product Model: AB121

- Manufacturer: ALSTOM Power Automation

- System Family: ADVANT / MICAF distributed control and protection platforms

- Module Type: Analog input interface (typically 8–16 channels)

- Input Types: Voltage (0–10 V), current (4–20 mA), or RTD (depending on variant)

- Resolution: 12–16 bits (system-dependent)

- Isolation: Channel-to-channel or group isolation (varies by configuration)

- Scan Rate: Typically 100–500 ms per channel

- Diagnostic Features: Limited LED indicators; no per-channel diagnostics

- Power Requirement: +5 VDC and ±15 VDC from system backplane

- Mounting: Proprietary rack/backplane in ALSTOM control chassis

- Operating Temperature: 0°C to 55°C

System Role and Downtime Impact

The AB121 serves as a foundational analog input module in legacy ALSTOM turbine and generator control systems, commonly found in fossil-fuel and hydroelectric power plants. It digitizes critical field signals—such as bearing temperature, lube oil pressure, and exhaust gas readings—for use in regulatory control, alarm annunciation, and protective interlocks. Failure of this module can result in loss of multiple process variables, potentially causing control loops to revert to manual mode, triggering nuisance alarms, or—more seriously—disabling safety-related shutdown logic. In non-redundant configurations, a single AB121 fault may necessitate derating or temporary shutdown of the prime mover until replacement is installed.

Reliability Analysis and Common Failure Modes

Although engineered for industrial environments, the AB121 is susceptible to age-related degradation due to its decades-long service life. Common failure modes include drift in analog-to-digital converter (ADC) circuits, leading to inaccurate readings; electrolytic capacitor aging in onboard power regulation stages, causing intermittent resets; and corrosion on backplane connectors, resulting in communication dropouts or channel loss. Additionally, exposure to electrical noise or ground loops—common in older plant wiring—can induce signal errors that mimic sensor faults.

A notable design limitation is the absence of granular diagnostics; technicians often cannot distinguish between a faulty module, bad sensor, or wiring issue without external calibration tools. The module also lacks hot-swap capability, requiring system downtime for replacement. Preventive maintenance should emphasize: (1) periodic loop calibration using precision signal sources; (2) thermal inspection of terminal blocks and backplane contacts; (3) verification of shield grounding integrity; and (4) functional testing during scheduled outages to validate signal fidelity across full range.

ALSTOM AB121

Lifecycle Status and Migration Strategy

ALSTOM discontinued the AB121 and its associated ADVANT platform years ago. GE Vernova no longer manufactures, repairs, or supports this hardware. Technical documentation is scarce, and spare parts exist only in limited surplus inventories—often without traceability or testing records. Continued reliance introduces significant operational risk, especially in regulated environments where equipment reliability is audited.

Short-term mitigation includes securing tested units from decommissioned sites or commissioning third-party firms for component-level refurbishment. However, these options become less viable as failure rates rise and expertise dwindles.

The sustainable solution is migration to a modern, supported control architecture such as GE’s Mark* VIe or an open-platform DCS with SIL-rated I/O. Equivalent analog input functionality can be achieved using modules compliant with IEC 61508 and offering enhanced features like HART communication, channel diagnostics, and remote configuration. Migration requires re-engineering I/O marshaling, updating control logic, and re-commissioning affected loops—but delivers long-term benefits in safety, maintainability, and integration with digital asset management systems. A phased approach, starting with highest-risk or most degraded modules, is recommended to balance cost, risk, and operational continuity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: