Description

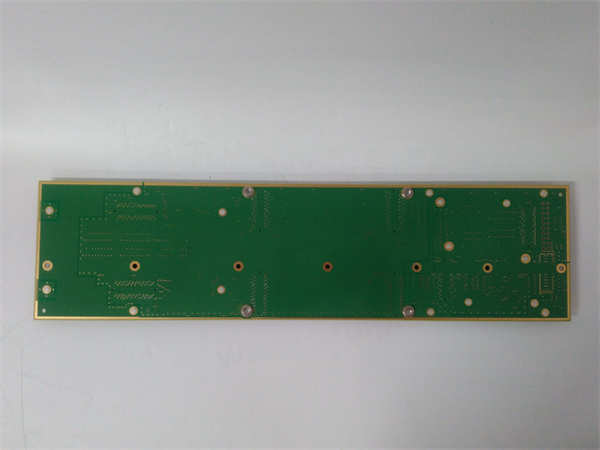

Key Technical Specifications (for Spare Parts Verification)

- Product Model: XXD129A01

- Manufacturer Part Number: 3BHE012436R0001

- Manufacturer: ABB

- System Family: PEC800 (Power Electronics Controller 800)

- Platform Used In: ACS1000, ACS6000 medium-voltage AC drives

- Function: Main backplane (motherboard) for PEC800 control unit

- Slots Supported: Hosts CPU, I/O, fiber optic interface, and power supply modules

- Connectors: High-density DIN 41612-type backplane connectors

- Power Rails: Distributes ±15 V, +5 V, +24 V to daughter cards

- Mechanical Interface: Mounts inside PEC800 enclosure with EMI shielding

- Revision Sensitivity: Hardware revision must match PEC800 firmware and module set

- Diagnostic Features: Limited—failure typically inferred from system boot errors or card communication loss

-

XXD129A01 3BHE012436R0001 PEC800-BP

System Role and Downtime Impact

The PEC800-BP backplane (XXD129A01 / 3BHE012436R0001) is the foundational hardware platform of the PEC800 controller, which governs gate firing, protection logic, and communication in ABB’s medium-voltage drive systems. It electrically and mechanically integrates all critical control modules—including the main CPU, gate driver interfaces, and fieldbus communication cards. If the backplane fails due to trace damage, connector wear, or power rail collapse, the entire PEC800 unit becomes inoperable, leading to immediate drive shutdown. In applications such as mine hoists, large compressors, or ship propulsion, this results in total loss of motor control, often triggering emergency stops and extended production halts. Because the PEC800 is a single-point control system with no hot-swap or redundant backplane option, failure necessitates full controller replacement or repair—making this component mission-critical.

Reliability Analysis and Common Failure Modes

Despite robust industrial construction, the PEC800-BP is vulnerable to long-term degradation due to thermal stress and mechanical fatigue. The most common failure mode involves cracked solder joints or delaminated PCB traces around high-current power pins, exacerbated by repeated thermal cycling during drive start-stop operations. Connector sockets can lose retention force over time, causing intermittent contact with daughter cards—manifesting as random resets or module detection failures. Another risk is corrosion on exposed contacts in humid or chemically aggressive environments, particularly if cabinet sealing has degraded. Although passive, the backplane contains filtering capacitors that can age, leading to voltage ripple and unstable logic operation. For preventive maintenance, technicians should inspect for physical board warping, clean connectors with contact enhancer, verify stable power rails under load using a test chassis, and ensure proper airflow around the PEC800 enclosure. Storing spare backplanes in anti-static, climate-controlled conditions is essential to preserve integrity.

-

XXD129A01 3BHE012436R0001 PEC800-BP

Lifecycle Status and Migration Strategy

ABB has discontinued the PEC800 platform, including the XXD129A01 backplane, with no direct successor within the same architecture. Official manufacturing ceased years ago, and new units are unavailable through ABB channels. Support is limited to legacy service contracts, and spare parts exist only in the secondary market—often without functional verification. Continuing to operate with this obsolete backplane carries severe risk: a single failure can immobilize multi-megawatt drive systems for weeks while sourcing a replacement. Short-term workarounds include sending failed units to specialized third-party repair firms capable of board-level rework or maintaining a cold spare PEC800 assembly. However, the strategic solution is migration to ABB’s Ability™ Enabled Drives, such as the ACS680 MV or DCS880 platforms, which feature modular, upgradable control systems with modern cybersecurity and remote diagnostics. Migration typically involves replacing the entire power stack or retrofitting existing transformers and switchgear with new control electronics—a capital investment that restores reliability, spares access, and compliance with current safety and communication standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: