Description

Key Technical Specifications (For Spare Part Verification)

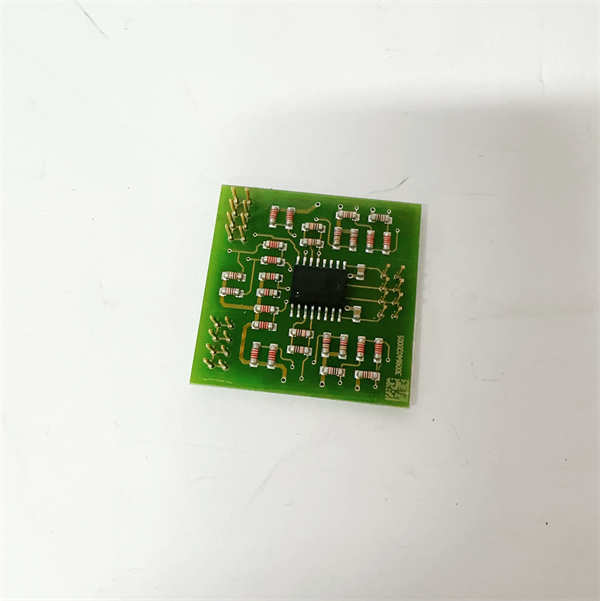

- Product Model: XVC722AE101

- ABB Order Code: 3BHB002751R0101

- Manufacturer: ABB

- Product Family: AC 800M Controller I/O Modules

- Communication Protocol: PROFIBUS DP (Decentralized Periphery)

- Operating Mode: Configurable as PROFIBUS Master or Slave

- Data Rate: Up to 12 Mbps (auto-baud or fixed)

- Electrical Interface: RS-485, 9-pin D-sub (male), isolated

- Isolation Voltage: 500 V RMS between logic and field sides

- Mounting: DIN rail within AC 800M I/O station

- Power Consumption: ~2.5 W (from backplane)

- Operating Temperature: 0°C to +60°C

- Certifications: CE, UL, CSA, IEC 61010

System Role and Downtime Impact

The XVC722AE101 serves as a critical fieldbus gateway in ABB AC 800M-based control systems, commonly deployed in power plants, water treatment facilities, and industrial manufacturing from the early 2000s through the 2010s. It connects the central controller to distributed I/O stations, variable frequency drives (VFDs), smart valve positioners, and other PROFIBUS-enabled field devices.

Failure of this module disrupts all communication on its assigned PROFIBUS segment. Depending on system architecture, this can result in:

- Loss of control over multiple motors or actuators

- Forced derating or shutdown of process units

- Cascading alarms in the Plant Information Manager or 800xA system

In non-redundant configurations—common in mid-tier applications—the loss of a single XVC722AE101 can halt an entire production line or auxiliary system. Even in redundant setups, replacement requires careful synchronization to avoid configuration mismatches.

Reliability Analysis and Common Failure Modes

Although designed for industrial robustness, units in service beyond 10–15 years exhibit several age-related failure mechanisms:

- RS-485 transceiver degradation: The isolated PROFIBUS driver ICs (e.g., ADM2486 or similar) are prone to failure due to repeated ESD events or ground potential differences, leading to bus-off conditions or intermittent communication.

- Electrolytic capacitor aging on the DC/DC isolation circuit causes voltage ripple, resulting in module resets or watchdog timeouts.

- Corrosion on the D-sub connector pins, especially in humid environments, increases contact resistance and induces signal reflections that corrupt PROFIBUS telegrams.

- Firmware corruption in rare cases, particularly after unclean power cycles, may render the module unresponsive during boot.

Design limitations include the lack of onboard diagnostics LEDs for bus traffic or error status (beyond basic “RUN” indication) and no built-in bus monitor function—making troubleshooting dependent on external tools like PROFIBUS analyzers or 800xA diagnostics.

Recommended preventive actions:

- Ensure proper PROFIBUS termination (120 Ω at both ends) and shielding grounded at one point only

- Perform periodic bus health checks using a protocol analyzer (e.g., Softing PB Analyzer)

- Inspect D-sub connectors for oxidation during maintenance outages

- Avoid daisy-chaining beyond recommended device counts or cable lengths

ABB XVC722AE101 3BHB002751R0101

Lifecycle Status and Migration Strategy

ABB has officially discontinued the XVC722AE101 (3BHB002751R0101) as part of its transition toward Ethernet-based field networks (e.g., PROFINET, Modbus TCP). While still supported in existing AC 800M systems under legacy software (e.g., Control Builder M v5.x), no new units are manufactured, and factory repair services are largely unavailable.

Current procurement options are limited to:

- Industrial surplus markets (prices typically 2,000, with no warranty)

- Third-party refurbishment services (capacitor replacement, re-flashing, functional test)

However, these carry risks of latent defects or counterfeit components.

For long-term reliability, ABB recommends migrating to modern communication modules such as:

- XVC762AE101 (PROFINET IO Controller)

- XVC732AE101 (Modbus TCP/IP Server/Client)

- XVC772AE101 (Ethernet/IP Adapter)

Migration involves:

- Updating the AC 800M hardware configuration in Control Builder M

- Replacing field devices or adding protocol gateways where necessary

- Revalidating network timing and I/O response performance

While not always requiring full system replacement, this transition future-proofs the installation against obsolescence, improves cybersecurity posture, and enables integration with ABB Ability™ digital platforms. For critical infrastructure, a phased migration during planned turnarounds is the optimal risk-balanced approach.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: