Description

Key Technical Specifications (For Spare Part Verification)

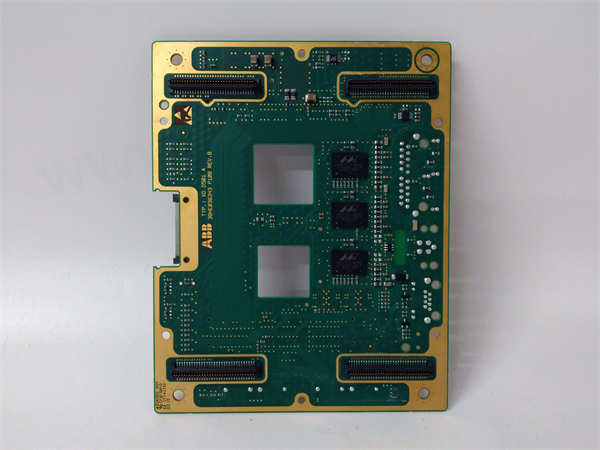

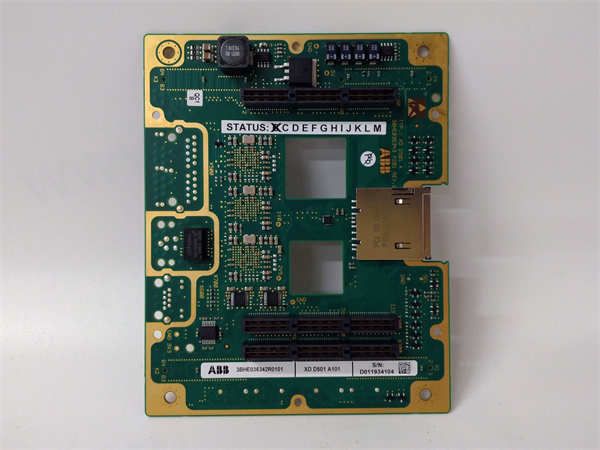

- Product Model: XDD501A101

- Manufacturer: ABB

- System Family: AC 800M controller in System 800xA architecture

- ABB Order Code: 3BHE036342R0101

- Input Channels: 16 isolated digital inputs

- Input Voltage Range: 24 VDC nominal (18–30 VDC acceptable)

- Input Current: ~7 mA per channel at 24 VDC

- Isolation: Channel-to-channel and channel-to-backplane isolation (reinforced insulation per IEC 61010)

- Diagnostic Coverage: Per-channel open-circuit and short-circuit detection

- Backplane Interface: Mounts on TB820/TB840 baseplate with S800 I/O bus connection

- LED Indicators: Power OK, Module OK, and individual channel status LEDs

- Safety Certification: Suitable for use in SIL 2/3 applications when configured in accordance with IEC 61508

-

XDD501A101 3BHE036342R0101

System Role and Downtime Impact

The XDD501A101 serves as a primary discrete signal acquisition module in ABB System 800xA installations across power, oil & gas, and chemical processing facilities. It interfaces with critical field devices—such as valve position feedback, pump run status, and emergency stop buttons—and delivers validated binary data to the AC 800M CPU for logic execution, alarm generation, and safety interlocks. In safety instrumented functions (SIFs), this module often forms part of the sensor layer for shutdown sequences.

If the XDD501A101 fails—due to internal circuit fault, backplane communication loss, or power instability—it may report incorrect states (e.g., “valve closed” when open). In non-redundant configurations, this can cause:

- False triggering of process trips

- Inhibition of startup sequences

- Loss of operator situational awareness

- Violation of safety function integrity in certified SIFs

Given its role in both basic process control and safety layers, unplanned failure carries operational and compliance consequences.

Reliability Analysis and Common Failure Modes

Although engineered for industrial environments, the XDD501A101 is now operating beyond its intended service life, with several age-related vulnerabilities:

- Input optocoupler degradation: The isolating optoisolators experience reduced CTR (current transfer ratio) over time, leading to missed transitions under marginal input voltage conditions.

- Backplane connector corrosion: Oxidation on the DIN rail baseplate contacts causes intermittent communication, often manifesting as sporadic channel dropouts without module fault indication.

- Power supply capacitor aging: Onboard decoupling capacitors lose capacitance, increasing susceptibility to voltage sags and noise-induced resets.

- LED indicator burnout: While not affecting function, failed status LEDs hinder troubleshooting during outages.

- Field wiring stress: Poorly terminated or unshielded cables introduce ground loops or EMI, overwhelming input hysteresis and causing chatter.

Recommended preventive actions include:

- Performing annual functional tests using a calibrated 24 VDC source on all channels

- Verifying diagnostic flags in Control Builder M or 800xA Workplace

- Inspecting terminal blocks for signs of overheating or loose connections

- Ensuring proper grounding of shielded field cables at one end only

- Avoiding unnecessary hot swaps to preserve backplane integrity

-

XDD501A101 3BHE036342R0101

Lifecycle Status and Migration Strategy

ABB has formally discontinued the XDD501A101 as part of the S800 I/O product evolution. The current recommended replacement is the XDD502A—a functionally equivalent but actively supported module with improved diagnostics and lower power consumption. However, direct substitution requires:

- Verification of terminal wiring compatibility (pinout is identical)

- Update of I/O configuration in Control Builder M

- Re-validation of any associated safety loops

Short-term risk mitigation includes:

- Securing tested spares with verified channel response and diagnostic behavior

- Maintaining accurate as-built documentation of field device mapping

- Implementing external signal monitoring for ultra-critical inputs

Long-term, facilities should integrate this module into a broader System 800xA lifecycle plan, potentially upgrading to S800 I/O Gen 2 modules that offer enhanced cybersecurity, predictive diagnostics, and seamless integration with ABB Ability™ asset performance tools.

Continued operation without a structured obsolescence strategy increases exposure to undetected failures, regulatory non-compliance in safety-critical applications, and escalating spare part costs. Proactive migration—not just inventory stocking—is essential for sustained operational integrity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: