Description

Key Technical Specifications (For Spare Parts Verification)

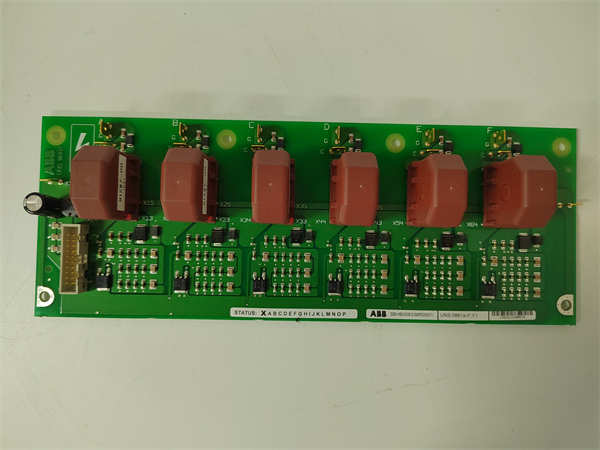

- Product Model: UNS0881A-P

- Manufacturer: ABB

- Associated System: ABB AC 800M / System 800xA

- Order Code: 3BHB006338R0001

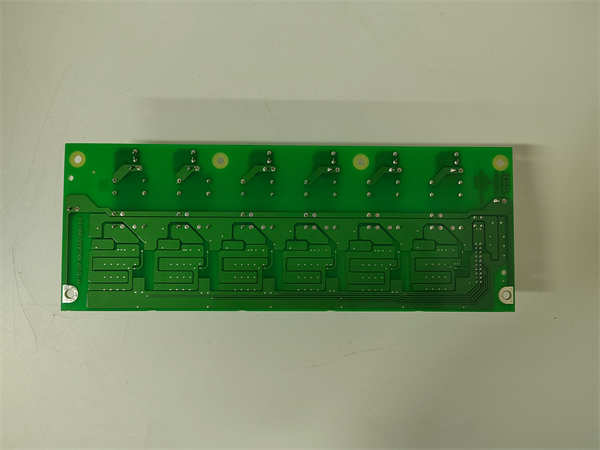

- Function: I/O module mounting base with screw-terminal field connections

- Compatibility: Supports multiple I/O module types (e.g., DI, DO, AI, AO from the TU series such as TU810, TU830)

- Wiring Type: Screw terminals for field cables (typically 0.5–2.5 mm²)

- Backplane Interface: Connects to CI854 or CI864 communication modules via DIN rail-mounted backplane

- Mechanical Format: Standard DIN rail mount, part of ABB’s modular I/O carrier system

- Physical Identification: Green housing, labeled “UNS0881A-P”, includes keyed slots to prevent incorrect module insertion

System Role and Downtime Impact

The UNS0881A-P is not an active electronic component but a critical mechanical and electrical interface in ABB AC 800M I/O stations. It serves as the foundation onto which functional I/O modules (such as digital input or analog output cards) are plugged. Without this base, field wiring cannot be connected, and modules cannot communicate with the controller via the backplane. If a base unit is damaged—due to terminal corrosion, physical breakage, or misalignment during maintenance—the entire I/O channel group becomes inoperable. In a process plant, failure of a single base can disable 8–16 I/O points, potentially causing a partial or full process shutdown if it affects safety interlocks, motor controls, or critical measurements. Replacement is not optional; it is mandatory for restoring I/O functionality.

Reliability Analysis and Common Failure Modes

Although passive, the UNS0881A-P is subject to several degradation mechanisms. The most common issue is terminal block damage caused by repeated wire insertion/removal, overtightening, or vibration-induced loosening leading to arcing and melting. Plastic housing embrittlement occurs over time in high-temperature environments (e.g., near power cabinets), making the unit prone to cracking during module replacement. Another subtle risk is misalignment of the guide rails or backplane connectors, which can bend pins on expensive I/O modules during insertion. While the base itself contains no electronics or batteries, its reliability hinges on mechanical integrity and proper installation. As a preventive measure, maintenance teams should inspect terminal tightness during routine rounds, avoid using excessive torque on screws, and store spare bases in climate-controlled conditions to prevent polymer aging. When replacing, always verify that the new (or used) base matches the exact revision to ensure compatibility with both the backplane and the I/O module form factor.

ABB UNS0881a-P,V1 3BHB006338R0001

Lifecycle Status and Migration Strategy

ABB has officially discontinued the UNS0881A-P as part of the broader phase-out of legacy AC 800M hardware. No direct replacement exists under a new order code; instead, ABB’s migration path involves upgrading to the AC 800M High Integrity or AC 500 platform, which use entirely different I/O architectures (e.g., TB5xx/TB8xx terminal bases). For sites still operating AC 800M systems, continuing to use UNS0881A-P carries significant risk: authentic units are scarce, counterfeit or refurbished units may lack proper dielectric strength, and pricing has increased substantially. In the short term, facilities should conduct an inventory audit and secure a strategic reserve of verified genuine units. Board-level repair is not feasible due to the mechanical nature of the component. Long-term, the recommended approach is to plan a staged I/O modernization—starting with non-critical loops—using ABB’s migration services to re-engineer I/O assignments onto current-generation terminal bases. This transition typically requires updated engineering in Control Builder M and may involve cabinet rewiring, but it eliminates dependency on obsolete infrastructure and restores access to full manufacturer support.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: