Description

Key Technical Specifications (For Spare Part Verification)

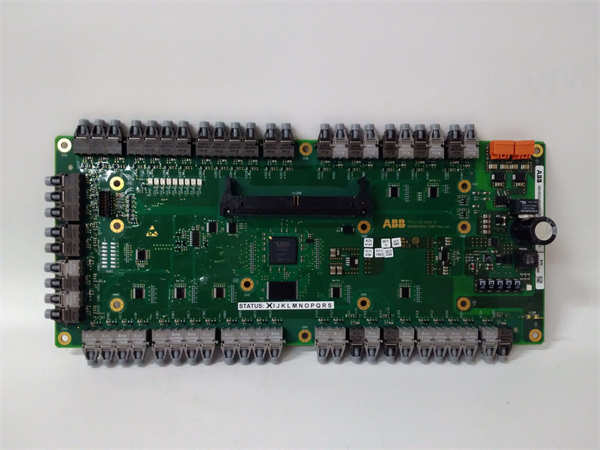

- Product Model: UNS0119A-P

- Manufacturer: ABB

- System Platform: AC 800PEC (Power Electronics Controller)

- Hardware Revision: V101 (must match exactly for compatibility)

- Function: Hosts real-time control algorithms, PWM generation, protection logic, and I/O synchronization

- Slot Position: Leftmost slot (CPU slot) in AC 800PEC chassis

- Communication Interfaces: Dual redundant fiber-optic links (for I/O sync), 10/100 Mbps Ethernet (engineering access), serial debug port

- Power Supply: +5 VDC and +3.3 VDC via backplane (no external power required)

- Onboard Memory: Flash for application storage; some variants use battery-backed RAM for configuration retention

- Compatible Backplane: Requires UNBP01 or UNBP02 series backplane

-

UNS0119A-P,V101 3BHE029153R0101

System Role and Downtime Impact

This module functions as the computational heart of the AC 800PEC system, deployed in mission-critical energy infrastructure such as HVDC converter stations, dynamic reactive compensation (STATCOM/SVC), and heavy industrial drives (e.g., rolling mills, mine hoists). It executes microsecond-level control loops that directly govern semiconductor switching (IGBTs/IGCTs) to regulate voltage, current, and power flow.

If the UNS0119A-P fails—due to software crash, communication loss, or hardware fault—the entire power electronics system enters a safe shutdown state. Consequences include:

- Immediate blocking of HVDC transmission, disrupting inter-regional power flow;

- Loss of dynamic voltage support from FACTS devices, risking grid instability;

- Emergency stop of industrial drives, potentially causing mechanical stress or production loss.

In utility or heavy-industry settings, such an event can trigger cascading operational and financial impacts, including regulatory reporting obligations and extended recovery timelines.

Reliability Analysis and Common Failure Modes

Despite a designed service life of 15–20 years, the V101 revision of this module exhibits predictable aging characteristics:

- Common Failure Modes:

- Dried-out electrolytic capacitors on the power rails, leading to excessive ripple and spontaneous resets;

- Depleted backup batteries (e.g., CR2032 or NiMH), resulting in loss of IP configuration or calibration data after power interruption;

- Degraded optical transceivers, causing intermittent or total loss of I/O synchronization over fiber;

- Micro-cracks in PCB traces due to thermal cycling, especially near clock and power circuits.

- Design Weaknesses:

- Reliance on battery-backed RAM for non-volatile data—failure to replace batteries proactively leads to configuration loss;

- Limited thermal margin in early designs, accelerating component wear in high-ambient environments;

- Susceptibility to ground loops and voltage transients if site grounding is suboptimal.

- Preventive Maintenance Recommendations:

- Replace backup batteries every 24 months and verify data retention;

- Perform annual infrared thermography to ensure module surface temperature remains below 65°C;

- Clean cabinet air filters and ensure forced ventilation is functional;

- Maintain secure backups of the full application project (.apc/.hex files) and network settings for rapid recovery.

-

UNS0119A-P,V101 3BHE029153R0101

Lifecycle Status and Migration Strategy

- Official Status and Risks:

ABB has formally declared UNS0119A-P obsolete. Continued operation entails significant risks:- Extremely limited spare availability with escalating costs;

- No access to firmware updates, security patches, or official engineering support;

- Third-party repairs lack access to original diagnostics, reducing success rates.

- Interim Mitigation Measures:

- Establish a minimum strategic spare inventory (recommended: 2+ units), tested and stored in climate-controlled conditions;

- Partner with specialized service providers for board-level repair (e.g., capacitor replacement, reballing);

- Implement a “cold standby” strategy in non-critical systems to enable manual failover during outages.

- Migration Path:

ABB’s recommended upgrade path is migration to the AC 800PEC e platform, centered on the UNS0120A-P (3BHE041627R0101) CPU module. This newer platform offers enhanced processing power, Gigabit Ethernet, and extended lifecycle support. The migration involves:- Hardware replacement (new CPU, compatible backplane, potential I/O adaptation);

- Application re-engineering using the updated PETool software environment;

- Re-certification of protection and control logic, particularly for grid-connected systems.

For budget-constrained sites, partial migration to an AC 800M + PCM600 architecture is feasible but requires redesign of PWM interfaces and protection schemes. A feasibility study should be initiated during the next scheduled major outage window.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: