Description

Key Technical Specifications (For Spare Part Verification)

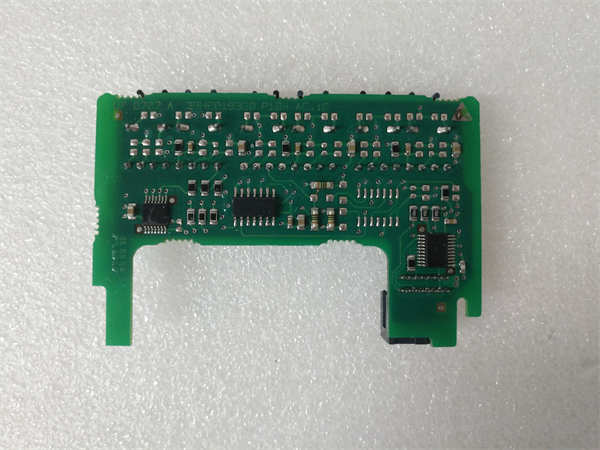

- Product Model: UFD203A101 3BHE019361R0101

- Manufacturer: ABB

- System Family: SATT 190 / SATT 200 distributed control system (predecessor to 800xA)

- Output Type: 8 channels, normally open (NO) relay contacts

- Contact Rating: 2 A at 250 V AC / 30 V DC (resistive load)

- Electrical Isolation: Galvanic isolation between logic and field sides via relay coils

- Backplane Compatibility: Requires UFD base rack (e.g., UFD900 series chassis) with compatible CPU and power modules

- Diagnostic Capability: Basic LED indication per channel (ON/OFF status); no advanced diagnostics

- Mounting: DIN-rail or rack-mounted within SATT cabinet

- Terminal Type: Screw-clamp terminals on removable connector block (typically 3BHE019362Rxxxx series)

- Response Time: <10 ms typical for contact closure/opening

- Power Consumption: Approx. 3 W from backplane

System Role and Downtime Impact

The ABB UFD203A101 serves as a key final control interface in SATT 190/200 systems, commonly deployed in fossil fuel power stations, district heating plants, and older industrial facilities. It directly energizes relays that switch auxiliary equipment—such as boiler feed pump starters, burner ignition circuits, or emergency dump valves. Unlike solid-state outputs, its electromechanical relays provide true galvanic separation and can switch both AC and DC loads. However, if the module fails (e.g., relay coil burnout or contact welding), commanded actions may not execute. In safety-critical sequences—like turbine trip or fire suppression activation—a failed output can delay or prevent protective action, potentially escalating an incident. Even in non-safety applications, loss of multiple outputs often forces manual intervention or unit derating, leading to production disruption. Recovery without a spare can take days due to the need for custom rewiring or temporary hardwired bypasses.

Reliability Analysis and Common Failure Modes

Despite its robust relay-based design, the UFD203A101 is now prone to age-related degradation. The most frequent failure mode is relay contact sticking or failure to close, caused by mechanical wear, contact oxidation, or arcing from inductive loads (e.g., solenoid valves). A second common issue is coil burnout, especially when outputs are frequently cycled beyond design life (typical relay mechanical life: 1–10 million operations). Additionally, terminal block corrosion in humid or chemically aggressive environments leads to high-resistance connections, causing voltage drop and incomplete actuation of downstream devices.

Design limitations include the absence of output feedback (no confirmation that contact actually closed) and reliance on mechanical components with finite lifespans. As a preventive measure, maintenance teams should: (1) perform annual contact resistance tests using a milliohm meter; (2) inspect terminal blocks for signs of overheating or corrosion; (3) verify actual field device operation during functional tests—not just module LED status; and (4) maintain at least one tested spare module with matching hardware revision.

ABB UFD203A101 3BHE019361R0101

Lifecycle Status and Migration Strategy

ABB has formally discontinued the UFD203A101 as part of its SATT product line phase-out. No new units are manufactured, and official support is limited to archived documentation. Continuing to operate this module introduces increasing risk of unplanned downtime due to component aging and spare scarcity.

Short-term mitigation includes sourcing verified used modules with full functional testing (including load simulation) or engaging third-party repair services for relay replacement. However, the sustainable solution is migration to a modern DCS platform. ABB’s strategic path is upgrade to the AC 800M system within 800xA, using solid-state or relay-based output modules such as the DO810 (24 V DC transistor) or DO820 (relay, 2 A). This transition requires: (1) replacement of SATT racks with AC 800M hardware; (2) re-engineering of output wiring via marshalling cabinets; and (3) conversion of control logic in Control Builder M. While requiring capital investment, this eliminates obsolescence risk, adds diagnostic feedback (e.g., open-circuit detection), and aligns the plant with current cybersecurity and operational standards. For sites extending SATT life, maintaining a “hot spare” UFD203A101—tested under actual load conditions—is a critical interim risk-control measure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: