Description

Key Technical Specifications (For Spare Parts Verification)

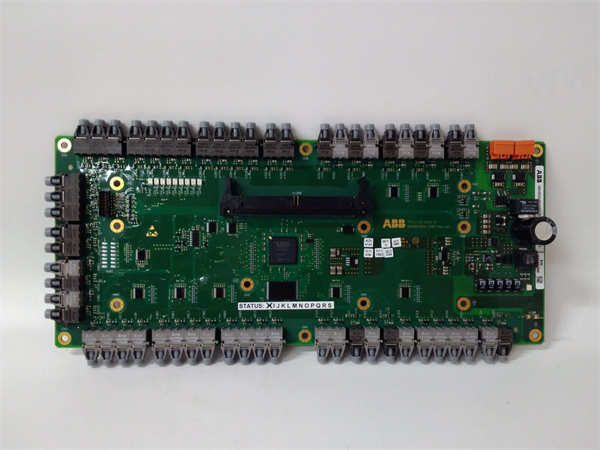

- Product Model: UFC921A101

- Manufacturer: ABB

- System Platform: Freelance 2000 / AC 800F DCS

- Order Code: 3BHE024855R0101

- Processor: Motorola PowerPC 603e, 66 MHz

- User Program Memory: 4 MB Flash

- RAM: 16 MB

- Communication Interfaces: Integrated S800 I/O bus; redundant Profibus DP port for remote I/O

- Power Supply: +5 VDC (via backplane)

- Mounting: Plug-in module for AC 800F rack (e.g., AF 800F), supports hot-swap in redundant configurations

- Status Indicators: Front-panel LEDs for RUN, STOP, ERROR, and I/O COMM

-

UFC921A101 3BHE024855R0101

System Role and Downtime Impact

The UFC921A101 is the central brain of an AC 800F controller station. In non-redundant installations, any hardware or software failure—such as a crash, communication lockup, or power anomaly—will cause immediate disconnection of all connected I/O subsystems (S800/S900 modules). This typically triggers an uncontrolled shutdown of the associated process segment. Common applications include chemical batch reactors, boiler combustion systems, and municipal water treatment plants. Given that these are often continuous processes, a single CPU failure can lead to unplanned downtime lasting hours or days, with significant operational and safety consequences.

Reliability Analysis and Common Failure Modes

Despite being out of production for over a decade, many UFC921A101 units remain in service due to robust initial design. However, component aging has significantly increased failure rates.

Common failure modes include:

- Flash memory corruption or write-protection failure: NAND Flash cells degrade after years of operation, leading to program load errors or checksum mismatches during boot.

- Dried-out electrolytic capacitors: Internal power-filtering capacitors lose capacitance over time, causing voltage instability and spontaneous resets—especially in high-temperature environments.

- Backplane connector oxidation: Corrosion or mechanical wear on gold fingers results in intermittent communication or complete signal loss.

- Profibus DP transceiver damage: Susceptible to electrical surges from field wiring, causing permanent port failure.

Design weaknesses include:

- No battery backup for runtime parameters (only program stored in Flash);

- Sensitivity to +5 VDC supply ripple (tolerance ±5%);

- Lack of modern cybersecurity features (e.g., no secure boot or encrypted communication).

Preventive maintenance recommendations:

- Clean backplane contacts every 24 months using electronics-grade contact cleaner;

- Monitor cabinet temperature—keep below 50°C to slow capacitor aging;

- Regularly back up application logic via Freelance Engineering Tool and verify Flash integrity;

- Maintain at least one fully tested spare module if operating in non-redundant mode.

-

UFC921A101 3BHE024855R0101

Lifecycle Status and Migration Strategy

ABB has officially ended support for the AC 800F platform. The UFC921A101 is no longer manufactured, and technical assistance is minimal. Continued operation carries substantial risks: scarcity of authentic spares, escalating costs, and inability to meet modern industrial security standards (e.g., IEC 62443).

Interim mitigation options include:

- Sourcing verified used or NOS (New Old Stock) units from reputable suppliers with full functional testing;

- Engaging specialized third-party repair services for board-level restoration (e.g., capacitor replacement, Flash reprogramming);

- Implementing temporary redundancy where rack hardware permits.

ABB’s recommended migration path is to ABB Ability™ System 800xA with AC 800M controllers. The direct functional successor is the PM864A (3BSE038327R1) or higher-performance variants. This transition requires:

- Re-engineering of control logic (Freelance projects cannot be directly imported into Control Builder M);

- Replacement of controller racks, power supplies, and I/O baseplates (though field wiring to S800 I/O can often be retained);

- Upgrade of operator stations to the 800xA environment.

While the upfront investment is notable, the long-term benefits include ongoing vendor support, enhanced cybersecurity, and seamless integration with MES and IIoT platforms—making it a justifiable total cost of ownership (TCO) decision for critical infrastructure. For budget-constrained facilities, phased migration—starting with the highest-risk or most frequently failing nodes—is a pragmatic approach.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: