Description

Key Technical Specifications (For Spare Part Verification)

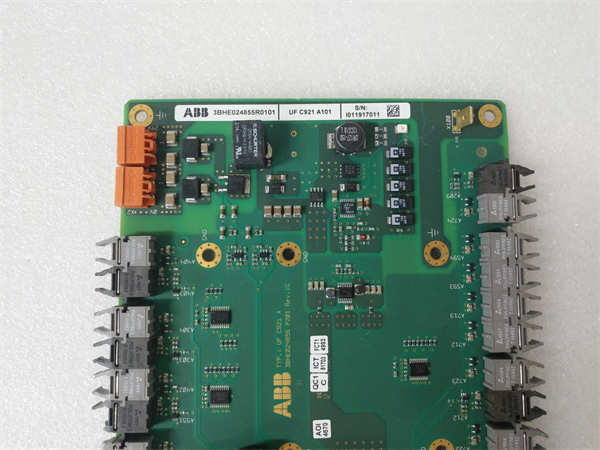

- Product Model: UFC921A101

- ABB Order Code: 3BHE024855R0101

- Manufacturer: ABB

- System Family: AC 800M (part of System 800xA architecture)

- Function: PROFIBUS DP master communication interface for AC 800M controllers

- Protocol Support: PROFIBUS DP (Class 1 and Class 2), compliant with IEC 61158

- Communication Speed: Up to 12 Mbps (configurable)

- Max Slave Devices: Supports up to 126 PROFIBUS slaves per segment

- Redundancy: Compatible with redundant AC 800M CPUs when used with appropriate cabling and GSD files

- Mounting: Plug-in module in AC 800M controller rack via backplane

- Diagnostics: Integrated LEDs for Power, Run, BF (Bus Fault), and Module Status

- Firmware Dependency: Requires specific firmware version aligned with Control Builder M project

System Role and Downtime Impact

The UFC921A101 is a critical enabler of distributed I/O in legacy ABB AC 800M systems, commonly deployed in power plants, water treatment facilities, and industrial process lines. It connects the central controller to remote I/O stations—often located hundreds of meters away—carrying real-time data for analog inputs, digital outputs, motor starters, and intelligent field devices.

In non-redundant configurations, which are typical in mid-sized installations, a failure of this module results in an immediate and total loss of communication with all downstream PROFIBUS devices. Consequences include:

- Loss of feedback from pumps, valves, and sensors

- Deactivation of interlocks and sequence logic dependent on remote signals

- Operator alarms flooding due to “device offline” diagnostics

- Potential forced shutdown if safety-critical measurements are lost

Recovery requires replacement with a functionally identical unit and re-establishment of bus parameters. Without a verified spare, downtime can exceed 48 hours, especially if original GSD files or network topology documentation are missing.

Reliability Analysis and Common Failure Modes

Despite solid industrial design, aging UFC921A101 modules exhibit predictable failure patterns after 10–15 years of service:

- PROFIBUS transceiver IC degradation: The RS-485 driver chips (e.g., SN65HVD series) fail due to repeated ESD events, ground potential differences, or cable faults, leading to “Bus Fault” (BF) LED activation.

- Onboard memory corruption: Configuration stored in flash becomes unreadable after excessive write cycles or power glitches, causing boot loops or incorrect baud rate settings.

- Backplane connector fretting: Thermal cycling induces micro-movements in edge connectors, resulting in intermittent communication with the AC 800M CPU.

- Power regulation instability: Aging capacitors in the local DC-DC converter cause voltage ripple, triggering unexpected resets during high bus traffic.

- GSD file mismatch: Replacement units must match the exact firmware and device profile used in the original Control Builder M project—a major challenge without engineering archives.

Recommended preventive actions:

- Maintain complete backups of PROFIBUS network configuration, including GSD files and device addresses

- Inspect terminal blocks and shielding continuity annually

- Monitor system logs for “Cyclic Communication Lost” or “Slave Not Responding” events

- Store at least two tested spares in ESD-safe, climate-controlled conditions

Lifecycle Status and Migration Strategy

ABB has discontinued the UFC921A101 in favor of modern Ethernet-based communication modules such as the CI874 (PROFINET) or CI867 (Modbus TCP / EtherNet/IP). While the AC 800M platform remains supported, this specific PROFIBUS module is no longer repairable or available new.

Short-term mitigation options include:

- Procuring verified-used units from decommissioned sites or ABB-certified surplus channels

- Engaging specialized third-party firms for board-level repair or firmware recovery

- Installing external PROFIBUS repeaters or diagnostic taps to isolate faults and extend module life

The long-term strategic path is migration to Ethernet-based field networks:

- Replace UFC921A101 with CI874 (for PROFINET) or CI867 (for Modbus TCP)

- Upgrade remote I/O stations to Ethernet-capable models (e.g., ABB TB5xx or third-party equivalents)

- Retain existing field wiring where possible using media converters or gateway devices

- Reconfigure communication in Control Builder M with minimal logic changes

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: