Description

Key Technical Specifications (For Spare Parts Verification)

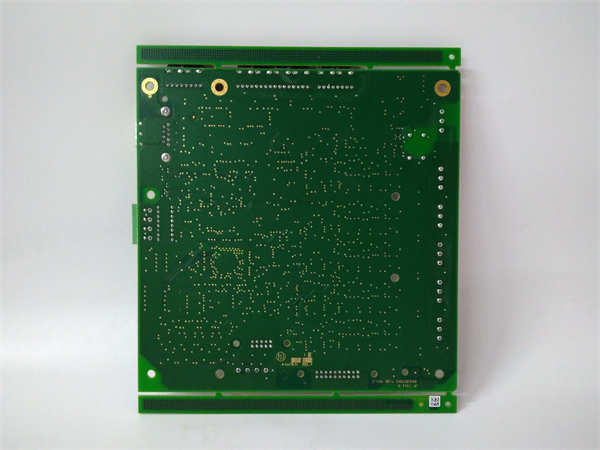

- Product Model: UFC911B106

- Manufacturer: ABB

- System Platform: Freelance 2000 / AC 800F DCS

- Order Code: 3BHE037864R0106

- Function: Profibus DP Master/Slave communication module

- Supported Protocol: Profibus DP (IEC 61158), compliant with ABB S800 I/O specification

- Communication Speed: Up to 1.5 Mbps (configurable)

- Max. Connected Stations: Up to 31 remote I/O stations per module

- Power Supply: +5 VDC via AC 800F backplane

- Mounting: Plug-in module for AC 800F controller rack

- Diagnostics: Front-panel LEDs for RUN, COMM, and ERROR status

System Role and Downtime Impact

The UFC911B106 serves as the critical fieldbus gateway in an AC 800F system, linking the central CPU (e.g., UFC921A101) to remote I/O clusters via Profibus DP. In typical architectures, a single UFC911B106 may manage dozens of I/O modules across multiple field junction boxes. If this module fails—due to hardware fault, firmware crash, or communication timeout—all connected I/O stations become unreachable. The result is immediate loss of sensor inputs and actuator outputs for that segment, often triggering safety interlocks or uncontrolled process drift. In continuous operations such as chemical plants or power auxiliary systems, this can lead to partial or full plant shutdown until the module is replaced or bypassed.

Reliability Analysis and Common Failure Modes

Although designed for industrial use, the UFC911B106 is now operating well beyond its intended service life. Many units have accumulated 15+ years of continuous operation, increasing vulnerability to component-level degradation.

Common failure modes include:

- Profibus transceiver IC failure: Caused by repeated electrical surges from field cabling or improper grounding, leading to one-way or total communication loss.

- Internal oscillator drift: Aging crystal components cause timing errors at higher baud rates (e.g., 1.5 Mbps), resulting in cyclic redundancy check (CRC) failures and station dropouts.

- Backplane connector fatigue: Repeated thermal cycling leads to micro-cracks in solder joints or pin wear, causing intermittent contact.

- Firmware corruption: Rare but possible due to power glitches during operation, especially if the system lacks clean UPS support.

Design weaknesses include:

- No built-in isolation on the Profibus port (relies on external isolators);

- Limited diagnostic granularity—only basic LED indicators, no detailed error logging without engineering tool access;

- Dependency on stable +5 VDC supply; voltage sags can trigger silent communication stalls.

Preventive maintenance recommendations:

- Inspect and reseat the module annually to ensure solid backplane contact;

- Verify Profibus termination resistors and cable shielding integrity at both ends;

- Monitor communication error counters via Freelance Engineering Tool during routine checks;

- Keep a verified spare module powered in a test rack periodically to prevent “shelf death.”

-

UFC911B106 3BHE037864R0106

Lifecycle Status and Migration Strategy

ABB has fully withdrawn the AC 800F platform from active support. The UFC911B106 is obsolete with no factory replacements. Continuing to operate systems dependent on this module carries significant operational risk due to unpredictable spare availability and lack of firmware or security updates.

Interim mitigation strategies include:

- Procuring only from suppliers who provide full functional test reports (including Profibus traffic simulation at multiple baud rates);

- Implementing external Profibus repeaters with diagnostics to isolate segment faults;

- In redundant CPU configurations, ensuring both controllers have independent UFC911B106 modules to avoid common-cause failure.

For long-term sustainability, ABB recommends migrating to the AC 800M platform under the Ability™ System 800xA architecture. The equivalent functionality is provided by the CI854A (3BSE020360R1) Profibus DP communication module, which integrates with PM86x-series CPUs. This migration requires:

- Replacement of the entire controller rack and power system;

- Reconfiguration of I/O addressing and GSD file integration in Control Builder M;

- Retraining of maintenance staff on the new engineering environment.

While migration is capital-intensive, it eliminates dependency on obsolete hardware and enables future-ready capabilities such as OPC UA, cybersecurity hardening, and cloud connectivity. For facilities not ready for full replacement, maintaining a small pool of rigorously tested spares—coupled with enhanced monitoring—is the most practical short-term strategy.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: