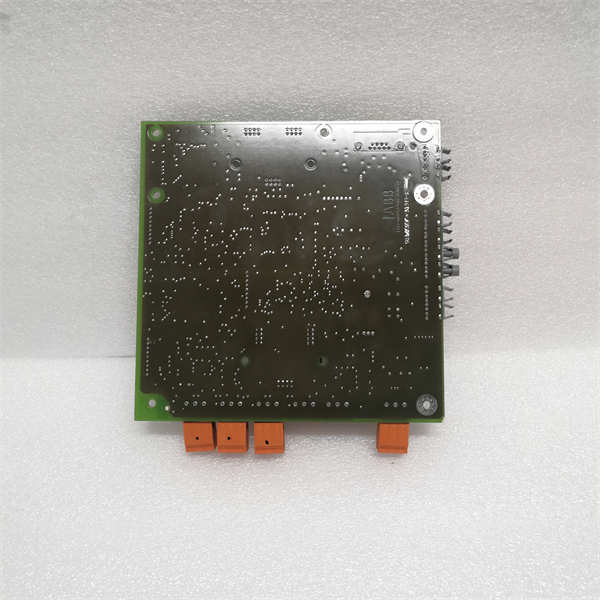

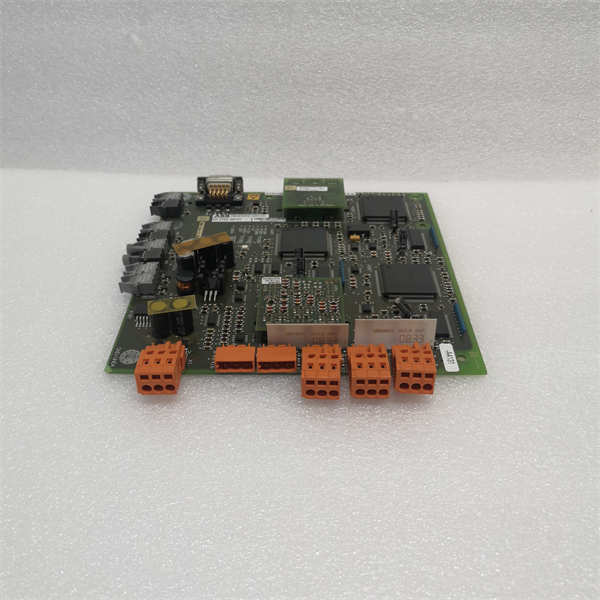

Description

Key Technical Specifications (Spare Part Verification)

- Product Model: UFC762AE101

- Manufacturer Part Number: 3BHE006412R0101

- Manufacturer: ABB

- Product Family: AC 800M Controller

- Processor Type: 32-bit RISC processor (PowerPC-based)

- Program Memory: Flash-based, non-volatile

- Execution Speed: ~0.15 µs per Boolean instruction

- Communication Interfaces: Dual redundant Profibus DP, serial port (RS-232/485), backplane to I/O modules

- Redundancy Support: Hot-standby with matching UFC762AE101 unit

- Mounting: DIN rail in AC 800M rack

- Operating Temperature: 0°C to +60°C

- Power Supply: Supplied via system backplane (24 V DC nominal)

System Role and Downtime Impact

The UFC762AE101 is the core processing unit of the AC 800M controller, widely deployed in ABB 800xA systems from the early 2000s through the 2010s. It executes real-time control logic for critical processes such as boiler combustion, turbine sequencing, and chemical dosing. In redundant configurations, it synchronizes state with its backup counterpart to enable seamless failover.

Failure of this CPU—especially in non-redundant applications—results in complete loss of automated control over all associated I/O and field devices. This typically forces a controlled or emergency shutdown of the process unit. Even in redundant setups, a single CPU failure increases vulnerability during maintenance windows or transient grid disturbances. Given its central role, replacement delays directly extend plant outage duration, with potential impacts on safety, environmental compliance, and revenue.

Reliability Analysis and Common Failure Modes

After 10–20 years of continuous operation, the UFC762AE101 is prone to several age-related failure mechanisms. The most critical is flash memory wear-out or corruption, which can cause boot failures or unexpected reboots due to checksum errors in the application code or firmware.

Other common issues include:

- Degradation of onboard electrolytic capacitors in the DC/DC converter circuits, leading to voltage instability and spontaneous resets

- Oxidation or fretting corrosion on backplane connectors, causing intermittent communication with I/O modules or the redundant partner

- Battery-backed RAM failure (in earlier firmware variants), resulting in loss of retained variables after power loss

The module provides basic status LEDs (RUN, STOP, I/O COMM) but lacks advanced diagnostics such as memory health indicators or temperature monitoring. Troubleshooting often requires connection to Control Builder M software or analysis of event logs from the 800xA engineering station.

Recommended preventive actions:

- Maintain a verified backup of the application project and firmware image

- Perform annual inspection of the CPU’s physical condition (bulging capacitors, discoloration)

- Clean backplane contacts during scheduled outages using electronic-grade contact cleaner

- Monitor for unexplained task overruns or communication timeouts as early warning signs

ABB UFC762AE101 3BHE006412R0101

Lifecycle Status and Migration Strategy

ABB has officially discontinued the UFC762AE101 (3BHE006412R0101). While still operational in thousands of legacy installations, it is no longer manufactured, and factory repair services are largely unavailable. New units cannot be ordered; remaining inventory exists only through industrial surplus channels or specialized refurbishers—at prices typically ranging from 7,000, often without warranty.

Short-term risk mitigation includes:

- Securing at least one tested spare CPU and storing it in ESD-safe, climate-controlled conditions

- Engaging third-party firms that offer board-level reconditioning (capacitor replacement, memory refresh)

- Implementing manual bypass procedures for non-critical loops during extended CPU unavailability

For long-term sustainability, ABB recommends migration to newer AC 800M CPUs such as the UFC760BE101 or UFC769AE101, which offer enhanced processing power, larger memory, and native Ethernet/IP or PROFINET support. Migration involves:

- Rebuilding the control application in a compatible version of Control Builder M

- Updating hardware configuration and I/O mapping

- Revalidating logic, alarms, and sequence timing

While requiring engineering effort, this transition extends system life, improves cybersecurity posture, and ensures continued access to technical support and spares. For facilities planning digital transformation, this step also enables integration with ABB Ability™ analytics and remote monitoring services.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: