Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: 0015-A2024

- Manufacturer: Applied Materials, Inc.

- System Family: Typically integrated into Centura, Producer GT, or Endura PVD/CVD platforms

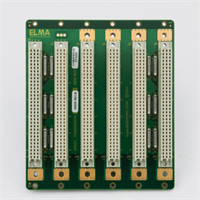

- Form Factor: Proprietary PCB assembly with custom connectors (often DIN 41612 or high-density AMP-style)

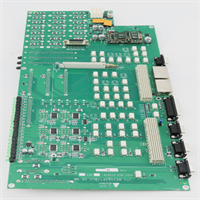

- Primary Function: Signal conditioning and control logic for variable capacitors or motorized stub tuners in auto-matching RF networks

- Input/Output Interfaces: Analog sensor feedback (capacitor position, forward/reflected power), digital control lines to stepper/servo actuators, RS-485 or proprietary serial link to main controller

- Power Requirements: +5 V, +12 V, ±15 V DC (typically supplied by system backplane)

- Firmware Dependency: Contains device-specific calibration maps; firmware version must match tool recipe database

- Environmental Rating: Designed for cleanroom operation (Class 1–10), low outgassing materials

- Diagnostic Indicators: Onboard LEDs for power, communication status, and fault codes (tool-specific interpretation required)

System Role and Downtime Impact

The 0015-A2024 serves as a critical intermediary in the RF delivery chain of legacy Applied Materials etch and deposition systems. It interprets commands from the main host controller and drives the mechanical or electronic components of the matching network to maintain optimal impedance between the RF generator and plasma load. During high-precision processes like dielectric etch or barrier metal deposition, even minor tuning delays or inaccuracies can cause plasma instability, leading to particle generation, non-uniform films, or wafer scrap.

If this module fails:

- The auto-match function is disabled, forcing manual tuning or process abort

- The tool may enter “RF Fault” or “Match Error” state, halting production

- Repeated attempts to run without proper matching can damage the RF generator or chamber components

- Mean time to recover (MTTR) can exceed 72 hours if a verified spare is not on hand, due to diagnostic complexity and tool recalibration requirements

In a 300mm fab, such downtime can cost hundreds of thousands of dollars in lost output and requalification expenses.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the 0015-A2024 is now well beyond its intended service life. Common failure mechanisms include:

- Electrolytic capacitor degradation: Onboard filtering capacitors dry out, causing voltage droop during actuator movement and triggering false overcurrent faults

- Connector fretting corrosion: Repeated thermal cycling in the tool environment leads to intermittent contact in high-pin-count backplane connectors

- Firmware corruption: Units with battery-backed SRAM lose calibration coefficients after prolonged idle periods, resulting in erratic tuning behavior

- Analog sensor front-end drift: Precision op-amps and ADC references age, causing position feedback errors that destabilize the control loop

Recommended preventive actions:

- Perform quarterly functional tests using AMAT’s diagnostic software (e.g., Aptiva or legacy Host Test)

- Inspect for bulging capacitors or discoloration near power regulators during PM events

- Maintain a log of match response times as a leading indicator of performance degradation

- Store spares in ESD-safe, temperature-controlled environments with periodic power cycling (every 6 months)

Lifecycle Status and Migration Strategy

Applied Materials has formally discontinued support for the 0015-A2024 as part of broader obsolescence management for pre-2010 tool architectures. No new units are available through official channels, and repair services are restricted to customers with legacy support agreements.

Continued operation carries significant risk:

- Secondary market units often lack traceability and may have been harvested from failed tools

- Mismatched firmware versions can cause tool-level communication errors that are difficult to isolate

- Lack of engineering documentation limits third-party repair success rates

Interim mitigation strategies include:

- Securing units only from suppliers providing full functional test reports under simulated RF load conditions

- Implementing board-level refurbishment (capacitor replacement, connector reflow) by specialized electronics repair firms

- Archiving original firmware and calibration files via tool diagnostics before failure occurs

The strategic path forward is tool retrofit or platform migration. Applied Materials offers Refurbished Tool Programs and Technology Refresh Packages that replace legacy RF control subsystems with modern, digitally managed architectures (e.g., based on the Endura Avenir or Producer® XP platforms). While capital-intensive, such upgrades restore OEM support, improve process repeatability, and reduce long-term spare parts dependency. For tools nearing end-of-life, a cost-benefit analysis should weigh ongoing maintenance risk against redeployment or retirement.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: