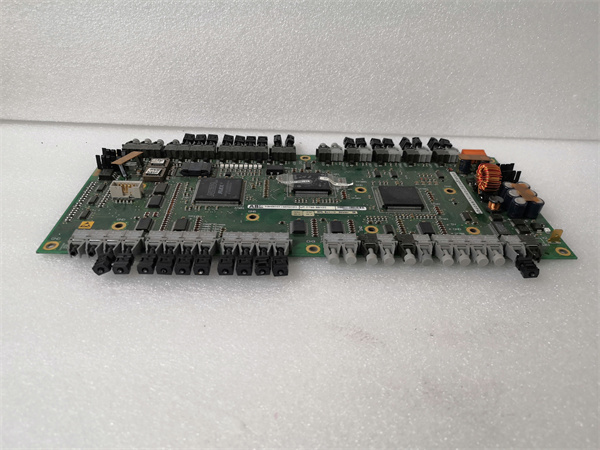

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: UFC760BE142

- ABB Part Number: 3BHE004573R0142

- Manufacturer: ABB Automation Products

- System Family: AC 800M (part of ABB’s Extended Automation System 800xA)

- Module Type: Main CPU / Controller Module

- Processor: Embedded PowerPC-based architecture

- Memory: Onboard RAM and flash (configuration stored on removable memory module, e.g., MB312A)

- Communication Interfaces:

- Dual redundant Profibus DP (for I/O)

- Ethernet (for engineering station, 800xA connectivity, and peer-to-peer)

- Serial port (RS-232 for diagnostics)

- Redundancy Support: Hot-standby with UFC760BE142 pair (via CRB810 redundancy link)

- Diagnostic Indicators: Multiple LEDs for RUN, STOP, I/O COMM, REDUNDANCY STATUS, and ERROR

- Power Consumption: ~10–15 W (varies with load)

- Mounting: DIN rail or rack-mounted within AC 800M cabinet

- Operating Temperature: 0°C to +55°C

System Role and Downtime Impact

The UFC760BE142 is the brain of the ABB AC 800M controller, responsible for executing safety-critical and process control logic in industries such as power generation, oil & gas, mining, and water treatment. In a redundant configuration, two UFC760BE142 modules operate in hot standby—one active, one synchronized. If the active unit fails, the standby takes over within milliseconds. However, if a second failure occurs before replacement (or in a non-redundant system), the entire control application halts, leading to:

- Loss of motor control, valve positioning, and interlocks

- Forced plant trip or emergency shutdown

- Potential safety incidents or environmental compliance breaches

Given its central role, the availability of functional spares directly impacts operational resilience and regulatory compliance.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the UFC760BE142—introduced in the early 2000s—is now susceptible to age-related degradation:

- Flash memory wear-out on internal storage, causing boot failures or corrupted firmware

- Capacitor aging in power regulation circuits, leading to voltage instability or spontaneous reboots

- Connector fatigue on backplane pins due to thermal cycling, resulting in intermittent communication

- Battery-backed RAM issues (if used with older memory modules), causing configuration loss

- Firmware/software version mismatches during replacement, triggering compatibility faults

A critical vulnerability is dependency on legacy components (e.g., discrete PowerPC support chips) that are no longer manufactured. Additionally, the module lacks modern cybersecurity features (e.g., secure boot, encrypted firmware), increasing risk in connected environments.

Recommended preventive maintenance:

- Regularly back up application code and hardware configuration via Control Builder M

- Monitor CPU load and scan time trends for early signs of degradation

- Inspect status LEDs and system logs for recurring sync or communication errors

- Verify redundancy switchover functionality during planned outages

- Store spare units with memory modules inserted in ESD-safe, climate-controlled conditions

ABB UFC760BE142 3BHE004573R0142

Lifecycle Status and Migration Strategy

ABB has formally declared the UFC760BE142 end-of-life, with last-time buy windows closed years ago. Official support is limited to extended service contracts, and newer versions of Control Builder M may drop compatibility. Spare parts are only available through third-party brokers, often without testing certification.

Short-term mitigation:

- Secure multiple tested, matched spares (including compatible memory modules like MB312A)

- Implement board-level repair programs with specialized industrial electronics firms

- Isolate AC 800M networks from corporate IT infrastructure to reduce cyber exposure

Long-term strategic path:

Migrate to ABB’s AC 800M High Performance (HP) series (e.g., UFC911BE) or transition to the next-generation Ability™ System 800xA with AC 900F/AC 500 platforms. These offer:

Migrate to ABB’s AC 800M High Performance (HP) series (e.g., UFC911BE) or transition to the next-generation Ability™ System 800xA with AC 900F/AC 500 platforms. These offer:

- Modern multi-core processors and larger memory capacity

- Enhanced cybersecurity (IEC 62443 compliance)

- Seamless integration with ABB Ability cloud analytics

- Continued software support and spare parts availability

Migration requires recompilation of control logic, I/O re-mapping, updated HMI graphics, and functional safety re-validation—a capital-intensive project best executed during major plant turnarounds. Given the high risk of sudden hardware failure, migration planning should be prioritized immediately to avoid unplanned, high-impact downtime.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: