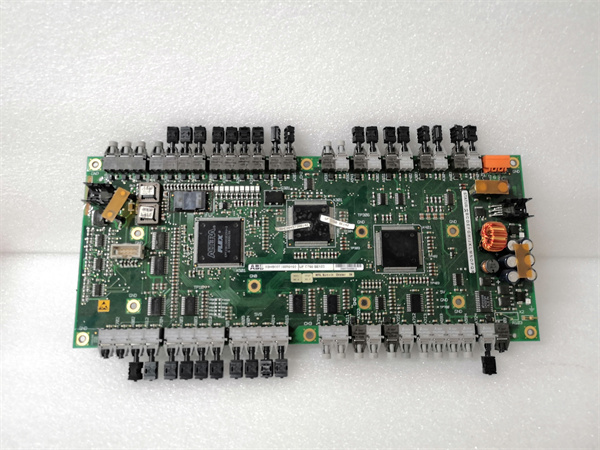

Description

Key Technical Specifications (For Spare Part Verification)

| Parameter | Specification |

|---|---|

| Product Model | UFC760BE142 / 3BHE004573R0142 |

| Manufacturer | ABB |

| System Family | SATT 190 / SATT 200 DCS (predecessor to 800xA) |

| Output Voltage | +24 V DC (regulated) |

| Output Current | Typically 10 A continuous (system-dependent) |

| Input Voltage | 115/230 V AC ±10%, 50/60 Hz (auto-ranging) |

| Redundancy Support | Yes – designed for parallel operation with identical unit in N+1 configuration |

| Mounting | Rack-mounted in SATT power chassis (e.g., UFC9xx series) |

| Cooling | Convection or forced air (depending on cabinet design) |

| Protections | Over-current, over-voltage, short-circuit, and thermal shutdown |

| Indicators | LED for POWER OK, FAULT, and sometimes REDUNDANCY STATUS |

| Efficiency | ~75–80% (typical for era) |

| Isolation | Reinforced isolation between AC input and DC output |

System Role and Downtime Impact

The UFC760BE142 is the backbone of the SATT 190/200 control system’s electrical infrastructure. It powers all logic processors (e.g., UFC710), I/O modules (e.g., PCD232A101 digital inputs, UFD203A101 outputs), and communication interfaces within a control rack. In redundant configurations, two UFC760BE142 units share the load; if one fails, the other should carry full demand without interruption.

However, if both units fail—or if a single non-redundant PSU fails—the entire SATT rack loses power. This results in an immediate and total loss of automatic control: motors stop responding, valves freeze, interlocks deactivate, and operator HMIs go blank. In critical applications like boiler control, turbine protection, or chemical reactor sequencing, this typically triggers a plant-wide emergency shutdown. Recovery requires not only PSU replacement but also full system reboot, logic reload (if battery-backed memory was lost), and safety revalidation—often taking 8–24 hours or more. In continuous-process industries, such an event can cost 2M+ in lost production and restart expenses.

Reliability Analysis and Common Failure Modes

Despite its industrial-grade design, the UFC760BE142 is now highly vulnerable due to age (many units installed in the 1990s–early 2000s). Common failure modes include:

- Electrolytic Capacitor Degradation:

- Input/output filter capacitors dry out over time, causing voltage ripple, instability, or complete shutdown.

- Often manifests as intermittent “brownout” behavior or spontaneous power cycling.

- Fan Failure (in forced-air variants):

- Overheating leads to thermal shutdown or component burnout.

- Relay or Switch-Mode Transistor Fatigue:

- High-cycle stress on power switching components causes open/short failures.

- Corrosion on Terminal Blocks or Backplane Connectors:

- Especially in humid or coastal environments, leading to high-resistance connections and voltage drop.

- Loss of Redundancy Coordination:

- Aging units may not share current properly, causing one to overload while the other idles.

🔧 Best Practice: Perform annual infrared thermography on PSU terminals, measure output ripple with an oscilloscope, and verify redundancy switchover during scheduled outages.

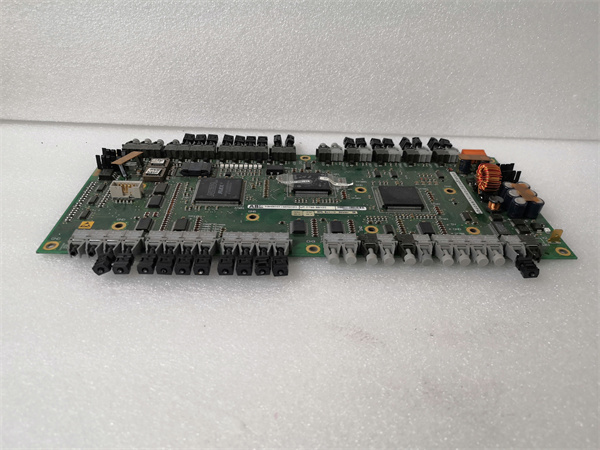

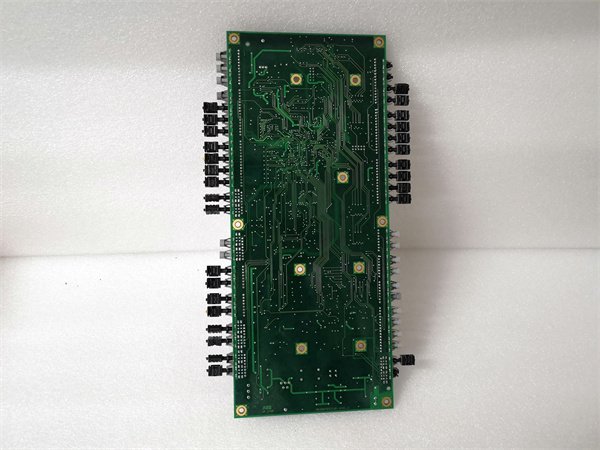

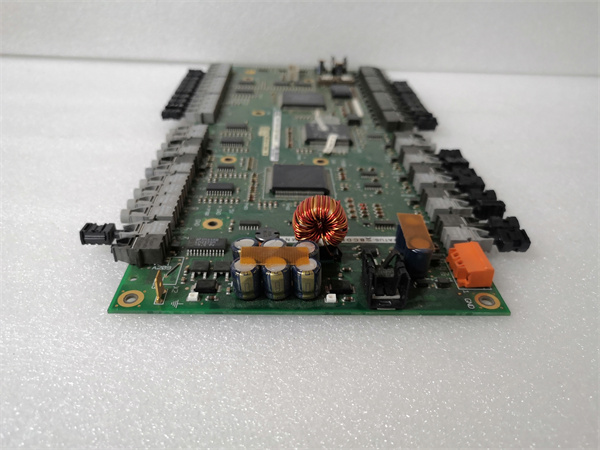

ABB UFC760BE142 3BHE004573R0142

Lifecycle Status and Migration Strategy

ABB has fully discontinued the UFC760BE142. No new units are manufactured, and official repair or calibration services are no longer offered. Technical documentation is archived but accessible only through legacy support channels.

Short-Term Mitigation:

- Maintain at least two tested spares in climate-controlled storage.

- Use third-party industrial power supplies (e.g., Mean Well, Siemens) as temporary replacements—but only with external isolation and voltage verification, as SATT logic is sensitive to noise and ground loops.

- Implement external UPS backup to reduce thermal cycling stress.

Long-Term Strategy:

Migrate from SATT 190/200 to ABB 800xA with AC 800M controllers. This includes:

- Replacing SATT racks with modern 800xA I/O and controller hardware.

- Upgrading power distribution to redundant DIN-rail PSUs (e.g., ABB CP240 series or equivalent).

- Recompiling control logic in Control Builder M.

- Validating all safety and regulatory loops per current standards (IEC 61511, etc.).

While capital-intensive, this migration eliminates single-point obsolescence risk, improves power efficiency, and restores access to cybersecurity updates and vendor support.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: