Description

Key Technical Specifications (For Spare Part Verification)

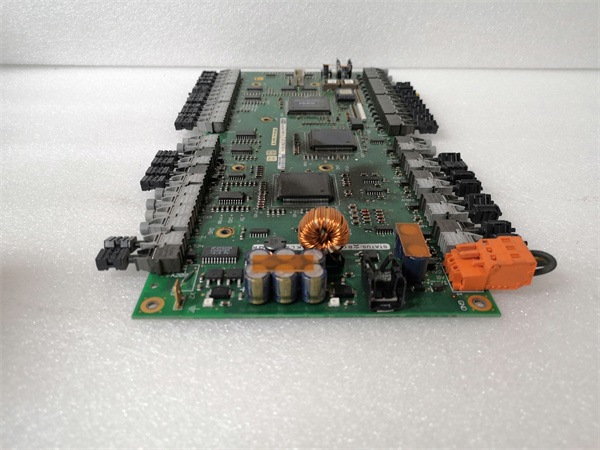

- Product Model: UFC760BE141

- ABB Order Code: 3BHE004573R0141

- Manufacturer: ABB

- System Family: AC 800M (PM86x series) within System 800xA

- Processor Type: Embedded PowerPC-based CPU with integrated co-processors

- Memory: Onboard application and configuration memory (non-volatile, battery-backed SRAM in some revisions)

- Redundancy Support: Hot-standby redundant configuration (requires paired UFC760BE141 units)

- Communication Interfaces: Dual optical or electrical PROFIBUS DP for I/O, dual Ethernet for controller-to-controller and engineering access

- Backplane Interface: Proprietary AC 800M bus for high-speed I/O data exchange

- Diagnostics: Integrated LEDs for status, error, and redundancy synchronization

- Mounting: Plug-in module in standard AC 800M rail-mounted chassis (e.g., CI854 base)

ABB UFC760BE141 3BHE004573R0141

System Role and Downtime Impact

The UFC760BE141 serves as the central processing unit in AC 800M-based control systems deployed across power generation, water treatment, mining, and oil & gas facilities. It runs safety-critical and regulatory-compliant logic for boiler controls, turbine sequencing, pump interlocks, and emission monitoring. In redundant setups, it synchronizes state with its partner to enable seamless failover.

If a UFC760BE141 fails—due to hardware fault, memory corruption, or backplane communication loss—the entire controller halts. In non-redundant systems, this results in immediate I/O freeze and process shutdown. Even in redundant pairs, a single failure degrades system resilience and often triggers alarms requiring urgent intervention. Replacement requires matching hardware revision, reinstallation of application code via Control Builder M, and full functional validation—a process that can take 24–72 hours without a pre-tested spare.

Reliability Analysis and Common Failure Modes

Despite industrial-grade design, units beyond 10–15 years exhibit consistent aging issues:

Battery-backed SRAM modules lose charge retention, leading to configuration loss during power cycles. Flash memory wear causes boot failures or corrupted firmware images. Optical transceivers on the PROFIBUS ports degrade due to heat and humidity, resulting in intermittent I/O communication. Backplane connector pins oxidize over time, increasing contact resistance and causing “Module Not Detected” errors. Additionally, internal DC/DC converters suffer from capacitor aging, leading to voltage instability under load.

Preventive maintenance recommendations include:

- Performing annual backup of application code and hardware configuration

- Verifying redundancy sync status and switchover functionality during outages

- Monitoring system logs for “Memory Error” or “Bus Fault” warnings

Storing spares in ESD-safe, dry environments with static shielding

Lifecycle Status and Migration Strategy

ABB discontinued the PM86x series, including the UFC760BE141, as part of its transition to the newer AC 800M PM866A/PM869 platforms and eventually to the Ability™ System 800xA with enhanced cybersecurity and cloud integration. Hitachi Energy no longer provides new units, repairs, or compatibility support for legacy firmware.

Short-term risk mitigation:

- Secure at least two tested UFC760BE141 modules with identical 3BHE004573R0141 codes

- Maintain a validated backup of the entire project in Control Builder M (v5.x or earlier)

- Document redundancy cabling and IP settings for rapid recovery

Long-term migration path:

- Upgrade to AC 800M PM866A or PM869 controllers, which offer pin-compatible chassis mounting and backward-compatible I/O

- Reuse existing field wiring, terminal bases, and most I/O modules

- Benefit from extended memory, faster scan times, native OPC UA, and IEC 62443 security features

- Leverage automated conversion tools in Control Builder M to migrate logic with minimal re-engineering

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: