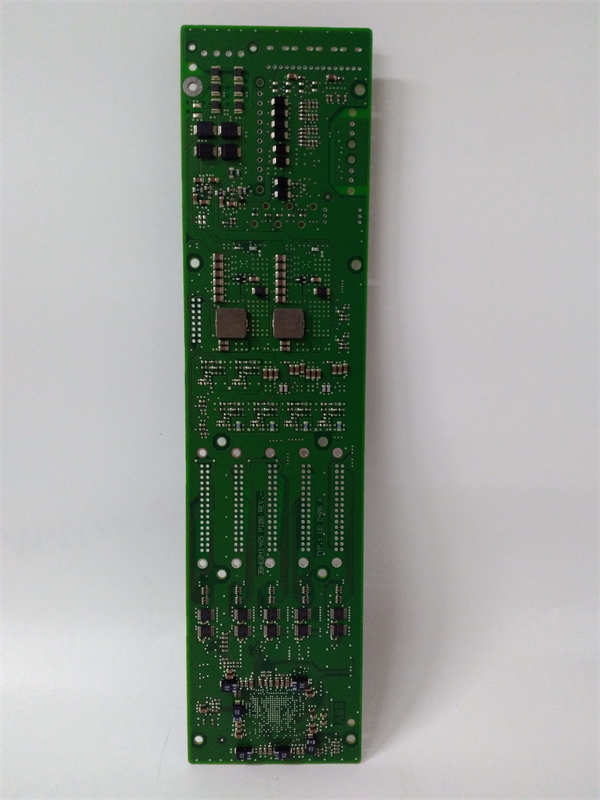

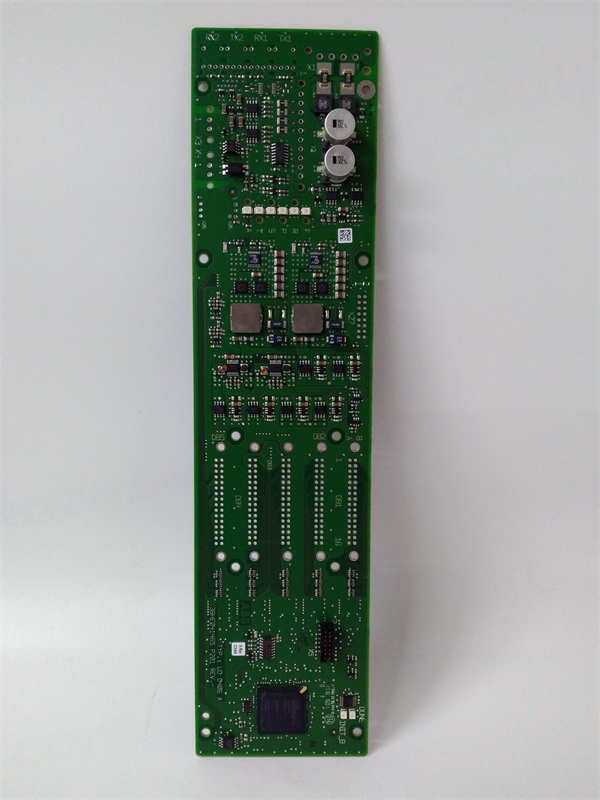

Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: UDD406A

- Manufacturer: ABB

- System Family: AC 800M controller in System 800xA architecture

- ABB Order Code: 3BHE041465P201

- Output Channels: 16 solid-state sourcing outputs (PNP-type)

- Output Voltage Range: 20.4–28.8 VDC (derived from external 24 VDC supply)

- Output Current per Channel: Max 0.5 A

- Total Module Current: Max 4 A (shared across all channels)

- Short-Circuit Protection: Electronic current limiting with auto-retry

- Isolation: Reinforced insulation between logic and field sides (per IEC 61010)

- Backplane Interface: Mounts on TB820/TB840 baseplate with S800 I/O bus

- LED Indicators: Power OK, Module OK, and individual channel status LEDs

- Diagnostic Features: Per-channel open-load and short-circuit detection reported via I/O bus

-

UDD406A 3BHE041465P201

System Role and Downtime Impact

The UDD406A is a key actuation interface in ABB System 800xA installations, commonly used in power plants, water treatment facilities, and industrial process lines. It converts digital commands from the AC 800M CPU into controlled 24 VDC signals that energize low-power field devices—such as pilot relays, alarm beacons, small solenoids, and positioner enable circuits.

If the UDD406A fails—due to internal semiconductor damage, power supply issues, or backplane communication loss—the connected devices become unresponsive. While not typically used for high-power motor control, its outputs often enable critical sequences (e.g., “allow start” signals to motor starters or reset commands to safety relays). A complete module failure can therefore:

- Prevent equipment startup

- Disable alarm annunciation

- Break safety interlock chains

- Cause partial process shutdowns

In non-redundant I/O configurations, this represents a single point of failure for up to 16 control functions.

Reliability Analysis and Common Failure Modes

Despite solid-state design, the UDD406A is subject to aging effects after years of continuous operation:

- Output transistor degradation: Repeated switching under inductive loads (e.g., relay coils without flyback diodes) causes cumulative stress on MOSFETs, leading to increased on-resistance, overheating, or short-circuit failure.

- Power rail instability: Aging decoupling capacitors reduce noise filtering on the internal logic supply, potentially causing erratic channel behavior during voltage transients.

- Backplane connector fatigue: Thermal cycling and vibration loosen the mechanical connection to the baseplate, resulting in intermittent communication or total dropout.

- Open-load misdiagnosis: Degraded field wiring or disconnected devices may trigger persistent “open-load” diagnostics, masking actual functional faults.

- LED indicator failure: Burnt-out status LEDs hinder visual troubleshooting but do not affect output functionality.

Recommended preventive maintenance includes:

- Verifying output voltage under load during scheduled outages

- Ensuring all inductive loads are protected with external flyback diodes

- Inspecting terminal tightness and signs of discoloration due to overheating

- Monitoring diagnostic logs in 800xA for recurring channel faults

- Avoiding operation near the 4 A total current limit to reduce thermal stress

-

UDD406A 3BHE041465P201

Lifecycle Status and Migration Strategy

ABB has officially discontinued the UDD406A as part of the S800 I/O product rationalization. The recommended replacement is the UDD407A, a functionally similar module with enhanced diagnostics, lower power consumption, and continued manufacturing support. Direct substitution is generally possible because:

- Pinout and terminal layout are identical

- Electrical ratings are comparable (0.5 A/channel, 4 A total)

- Configuration in Control Builder M requires minimal changes

However, validation of load compatibility and re-testing of associated logic sequences are essential.

Short-term risk mitigation involves:

- Securing at least one verified spare UDD406A with functional channel testing

- Documenting exact load types and current draw per channel

- Implementing external monitoring for critical outputs (e.g., auxiliary contact feedback)

Long-term, asset owners should incorporate this module into a broader I/O modernization plan, potentially migrating to S800 I/O Gen 2 platforms that offer predictive health monitoring, improved cybersecurity, and integration with ABB Ability™ cloud services.

Continued use of the UDD406A without a formal obsolescence strategy increases the likelihood of unexpected downtime, especially as semiconductor wear accumulates beyond design margins. A proactive migration approach ensures sustained reliability and compliance with evolving operational technology standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: