Description

Key Technical Specifications (For Spare Part Verification)

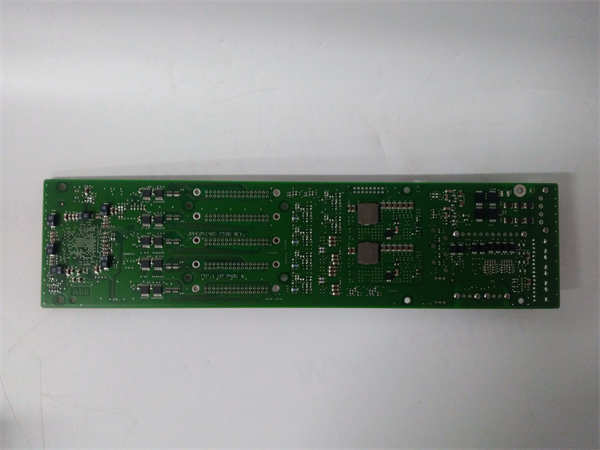

- Product Model: UDD406A

- Manufacturer: ABB

- System Family: S800 I/O for AC 800M (part of System 800xA architecture)

- ABB Order Code: 3BHE041465P201

- Output Type: 16 independent electromechanical relays (normally open, SPST)

- Contact Rating: 2 A at 250 VAC / 30 VDC (resistive load)

- Electrical Isolation: Relay contacts isolated from logic side; no channel-to-channel isolation

- LED Indication: One status LED per channel (ON = output energized)

- Backplane Compatibility: Requires S800 baseplate (e.g., TB840 or TB850) with standard DIN-rail mounting

- Power Consumption: Approx. 3.5 W (logic power from backplane; coil drive internal)

- Operating Temperature: 0°C to +60°C

-

UDD406A 3BHE041465P201

System Role and Downtime Impact

The UDD406A serves as a critical actuation interface in legacy ABB AC 800M control systems, commonly found in power generation, water treatment, and industrial manufacturing facilities. It translates controller logic signals into physical switching actions—activating pumps, opening dampers, triggering alarms, or enabling safety interlocks. Because it uses electromechanical relays, it is often specified for applications requiring galvanic isolation or switching of mixed-voltage loads. However, this also makes it a wear-prone component. If the module fails—due to relay contact welding, coil burnout, or logic-side circuit degradation—the associated field devices become unresponsive. In safety-critical sequences (e.g., emergency shutdown), such a failure could prevent proper execution of protective actions, leading to process deviation, equipment damage, or regulatory non-compliance. Unlike solid-state outputs, relay modules cannot fail silently; they typically manifest as stuck-on or stuck-off states, both of which disrupt automated operations.

Reliability Analysis and Common Failure Modes

The primary weakness of the UDD406A lies in its electromechanical relays, which have a finite mechanical and electrical life—typically rated for 100,000 to 500,000 operations under ideal conditions. In real-world applications with frequent cycling (e.g., pump control), relays can wear out prematurely. Common failure modes include:

- Contact welding: Caused by inductive load arcing or overcurrent, resulting in a permanently closed output.

- Coil open-circuit: Due to thermal stress or voltage spikes, leading to a dead channel.

- Contact oxidation: In low-current signaling applications, relays may develop high contact resistance, causing intermittent signal dropout.

Additionally, the PCB-level components—such as driver transistors and decoupling capacitors—can degrade over time, especially in high-temperature cabinets with poor ventilation. The lack of channel-to-channel isolation also means a short on one output can affect neighboring circuits. Preventive maintenance should focus on: periodic functional testing of each channel under load, visual inspection for burnt relay housings or discoloration, monitoring ambient temperature around the I/O rack, and avoiding use in high-cycle (>1 Hz) applications where solid-state alternatives would be more suitable.

-

UDD406A 3BHE041465P201

Lifecycle Status and Migration Strategy

ABB officially discontinued the UNS0122A-P as part of the broader phase-out of the AC 800M PM86x platform. While the AC 800M architecture continues in newer variants (e.g., PM866A with updated carriers), the UNS0122A-P has no direct drop-in successor. Continued use carries significant risk: inventory is exhausted at ABB, forcing users to rely on third-party brokers where counterfeit or previously failed units may circulate. Lead times are unpredictable, and pricing has increased by 300–500% over the past five years.

As an interim measure, facilities should secure at least one verified spare per critical controller and consider board-level refurbishment services that replate connectors and reinforce PCB traces. However, these are temporary fixes.

The recommended migration path is a full transition to the AC 800M PM866A/PM867 platform or, for greenfield compatibility, to ABB’s Ability™ System 800xA with latest-generation controllers. This requires hardware replacement, application code conversion (from CBM to PG2), and I/O re-commissioning. ABB provides migration tools and engineering services to streamline this process, and the investment is justified by restored access to support, cybersecurity updates, and long-term spare availability. For sites unable to fund full migration, a risk-mitigated approach includes documenting exact configuration, isolating non-critical functions, and implementing enhanced monitoring to detect early signs of carrier-related instability.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: