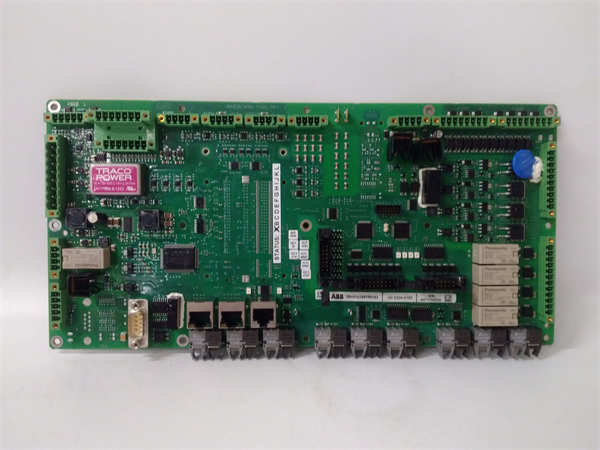

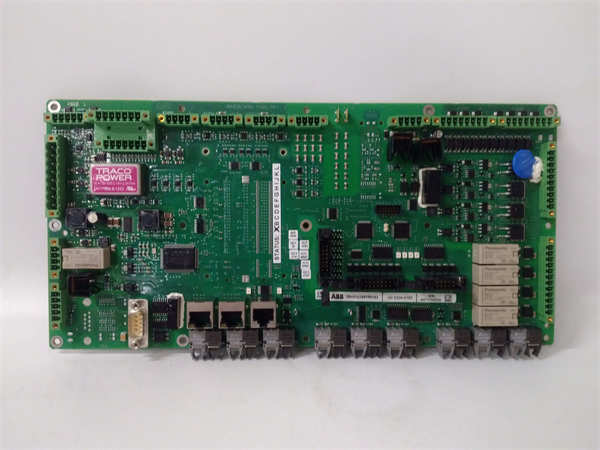

Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: UCD224A103

- Manufacturer: ABB

- System Family: S800 I/O for AC 800M (part of System 800xA architecture)

- ABB Order Code: 3BHE023681R0103

- Input Channels: 4, fully differential and individually isolated

- Supported Signal Types: 0/4–20 mA (loop-powered or passive), 0–10 V, ±10 V

- Input Impedance: ~250 Ω for current inputs; >100 kΩ for voltage inputs

- HART Support: Transparent pass-through on all channels (no internal modem; requires external HART multiplexer or handheld)

- Isolation: Channel-to-channel and channel-to-backplane isolation rated at 300 VAC RMS

- Accuracy: ±0.1% of full scale (typical at 25°C)

- LED Indication: One per channel (green = normal, red = fault)

- Backplane Compatibility: Requires S800 baseplate (e.g., TB840/TB850) with standard DIN-rail mounting

-

UCD224A103 3BHE023681R0103

System Role and Downtime Impact

The UCD224A103 is a foundational analog input module in legacy ABB AC 800M-based process control systems, widely deployed in power plants, refineries, and chemical facilities. It interfaces directly with field transmitters to digitize critical process variables such as boiler drum level, turbine bearing temperature, or reactor pressure. Each channel operates independently with galvanic isolation, preventing ground loops and enhancing noise immunity—essential in electrically noisy industrial environments. If this module fails—due to sensor supply loss, ADC drift, or isolation barrier breakdown—the associated control loops lose their primary feedback signal. This can trigger alarms, force loops into manual mode, or—more severely—cause cascade trips if the signal is used in safety interlocks (e.g., high-pressure shutdown). Because analog signals are continuous, even partial degradation (e.g., offset error) may go undetected until process deviation occurs, making reliability paramount.

Reliability Analysis and Common Failure Modes

Although designed for industrial robustness, the UCD224A103 is now operating beyond its intended service life, exposing several aging-related vulnerabilities. The most common failure points include:

- Degraded input isolation barriers: Over time, the optocouplers and isolation amplifiers can lose performance due to thermal stress, leading to crosstalk or ground-loop-induced noise.

- Sensor supply voltage drift: The internal 24 VDC loop power source may sag under load due to aging regulators, causing transmitter brownout and signal dropout.

- ADC reference instability: Precision voltage references on the analog front-end can drift, introducing offset or gain errors that compromise measurement accuracy.

- Connector corrosion: Moisture ingress in non-climate-controlled panels can oxidize terminal block screws or backplane contacts, increasing contact resistance and causing intermittent readings.

Preventive maintenance should include periodic calibration verification against a known standard, inspection of terminal tightness and signs of overheating, monitoring of channel diagnostic LEDs, and ensuring ambient temperature remains within specification. Special attention should be paid to modules in high-humidity or high-vibration areas, where mechanical fatigue accelerates failure.

-

UCD224A103 3BHE023681R0103

Lifecycle Status and Migration Strategy

ABB has discontinued the UCD224A103, with official support redirected to newer S800 analog modules such as the UCD224A105 (enhanced diagnostics) or UCD227A (higher density). No direct drop-in replacement exists for the 3BHE023681R0103 revision, and new units are unavailable from ABB. Continued use relies on surplus inventory, which carries risks of calibration drift, hidden damage, or counterfeit labeling. Short-term risk mitigation includes maintaining a calibrated spare unit, implementing redundant measurements for critical loops, and documenting baseline signal behavior to detect early anomalies. For long-term sustainability, ABB recommends migrating to current-generation S800 analog input modules, which offer improved accuracy, built-in self-diagnostics, and better integration with modern asset management tools via Asset Optimization in System 800xA. This migration requires updating the hardware configuration in Control Builder M, re-verifying loop tuning, and potentially reassigning I/O tags—but it eliminates future obsolescence exposure and enhances system resilience. Facilities unable to execute full migration should establish a formal obsolescence management plan, prioritizing high-criticality analog inputs for early replacement.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: