Description

Key Technical Specifications (For Spare Parts Verification)

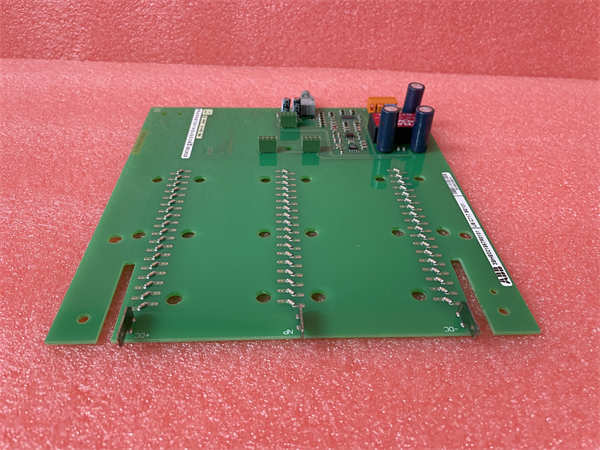

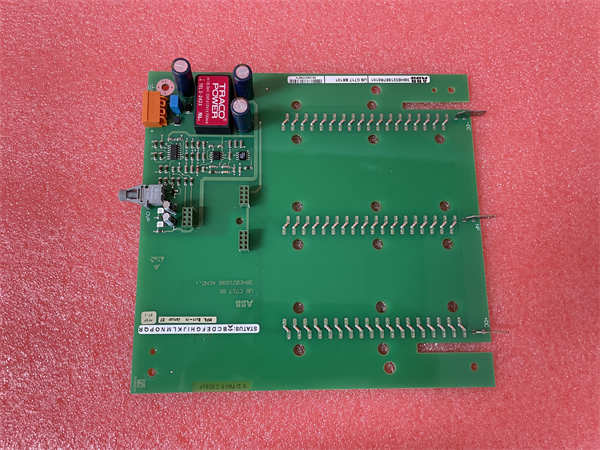

- Model Number: UBC717BE101

- Manufacturer: ABB

- System Family: Advant Controller 450 (AC 450) – part of the MasterPiece 200/Advant OCS platform

- Module Type: Controller base unit (backplane carrier)

- Compatible CPUs: PM510V16, PM511V16 (Master/Slave redundant pairs)

- Slot Capacity: Supports up to 8 I/O or communication modules in a single rack

- Redundancy Support: Yes – designed for dual-rail redundant AC 450 configurations

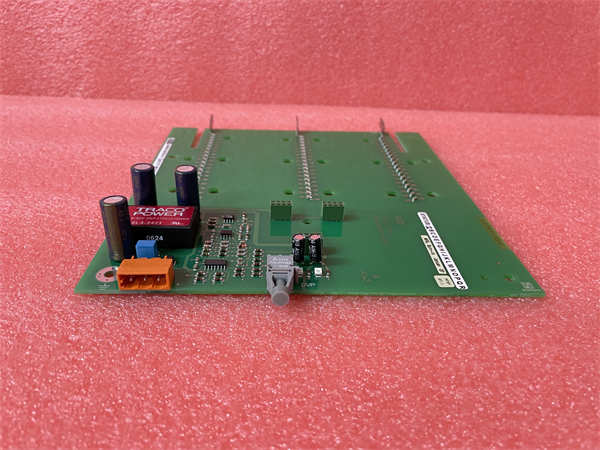

- Power Input: +5 VDC and +24 VDC from system power supplies via backplane connectors

- Mechanical Form Factor: 19-inch rack mountable, 6U height

- Bus Architecture: Proprietary parallel backplane bus for high-speed CPU-to-I/O communication

- Diagnostic Indicators: Integrated LEDs for power, CPU status, and redundancy sync

System Role and Downtime Impact

The UBC717BE101 serves as the foundational hardware platform for the ABB AC 450 controller, commonly deployed in power generation, water treatment, and heavy industrial facilities installed between the late 1990s and early 2010s. It is not a processing unit itself but provides the critical electrical and mechanical interface that allows the CPU (e.g., PM511V16) and I/O modules to function as a cohesive control system. In a redundant setup, two UBC717BE101 units operate in tandem to ensure continuous operation during failover.

If this base unit fails—due to cracked traces, connector damage, or power distribution faults—the entire controller rack becomes inoperable. Since the AC 450 typically controls core processes (e.g., boiler feedwater, turbine sequencing, or chemical dosing), such a failure can result in a complete plant trip or forced manual operation, carrying significant safety, environmental, and financial consequences. Unlike modular I/O cards, the base unit cannot be bypassed or hot-swapped in most legacy installations.

Reliability Analysis and Common Failure Modes

Although mechanically robust, the UBC717BE101 is susceptible to long-term degradation due to its age and operating environment. Common failure mechanisms include:

- Backplane trace fatigue: Repeated thermal expansion/contraction over 15–25 years can cause micro-cracks in PCB traces, especially near high-current power paths, leading to intermittent voltage drops or total loss of power to modules.

- Connector pin corrosion or wear: The edge connectors that interface with CPU and I/O modules are prone to oxidation in humid environments, resulting in poor contact resistance and communication errors.

- Capacitor leakage or bulging: Onboard decoupling capacitors may degrade, causing local power instability that affects CPU synchronization in redundant systems.

- Mechanical stress damage: Improper module insertion/removal over decades can warp the guide rails or crack mounting points, compromising module seating.

Design weaknesses include lack of conformal coating (in early revisions) and reliance on precise mechanical alignment for reliable bus communication. For preventive maintenance, site engineers should:

- Perform annual visual inspection for PCB discoloration, capacitor swelling, or bent pins

- Measure backplane voltages at test points under load to detect droop

- Clean module slots with ESD-safe contact cleaner during scheduled outages

- Ensure proper airflow to prevent localized overheating

ABB UBC717BE101 3BHE021887R0101

Lifecycle Status and Migration Strategy

ABB has formally discontinued the AC 450 platform, including the UBC717BE101, with no direct replacement offered within the same architecture. Official support is limited to extended maintenance contracts, and new units are unavailable through ABB channels. Continued operation relies entirely on existing inventory or refurbished units, introducing supply chain vulnerability.

As an interim measure, facilities may:

- Stockpile tested, functional spares with documented performance history

- Engage specialized third-party repair services capable of board-level rework

- Implement external watchdog systems to detect controller hang states

For strategic sustainability, ABB recommends migration to the System 800xA platform with AC 800M controllers (e.g., PM866). This transition involves:

- Replacing the entire AC 450 rack with a new AC 800M station

- Converting application logic from Composer/PG2 to Control Builder M

- Retaining field wiring through compatible I/O modules (e.g., S800 series with terminal units like TU842)

- Revalidating all control and safety interlocks per current standards

Given the UBC717BE101’s role as a single point of failure in aging infrastructure, organizations should treat its obsolescence as a Tier-1 operational risk and prioritize either secure sparing or structured migration planning.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: