Description

Technical Specifications (For Spare Parts Verification)

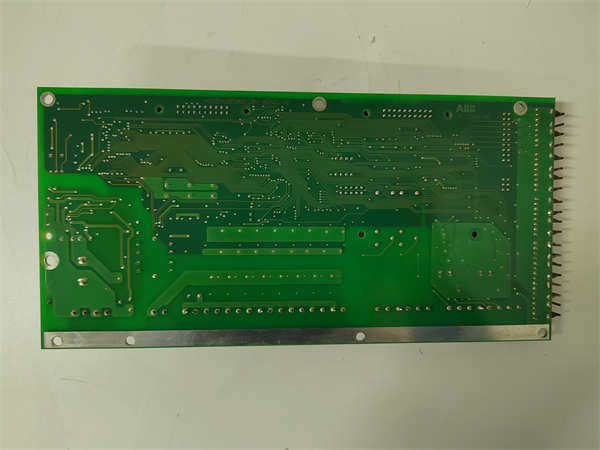

- Model: UAC389AE02 / HIEE300888R0002

- Manufacturer: ABB

- System Family: AC 800M Automation System (part of System 800xA)

- Module Type: Controller base unit (carrier) for PM8xx series CPUs

- Compatible CPUs: PM851, PM856, PM860, PM864, PM865 (depending on firmware and slot configuration)

- Backplane Interface: Proprietary high-speed parallel bus for communication with I/O modules via CI8xx communication interfaces

- Power Input: +24 VDC via redundant power supply modules (e.g., SA811)

- Mechanical Format: 19-inch rack mountable, occupies 7 module slots in an AC 800M chassis

- Diagnostic Features: Integrated LEDs for power, module status, and error indication

- Redundancy Support: Enables CPU and power supply redundancy when used in dual-controller configuration

- Physical Dimensions: Standard AC 800M form factor (approx. 230 mm height, 280 mm depth)

System Role and Downtime Impact

The ABB UAC389AE02 (HIEE300888R0002) is the physical and electrical foundation of the AC 800M controller. It does not execute logic itself but hosts the CPU, communication modules, and power interfaces that enable the entire control system to function. In applications such as power plant boiler controls, water treatment sequencing, or mining conveyor systems, this base unit is part of the central control node.

If the base unit fails—due to cracked PCB traces, damaged backplane connectors, or internal short circuits—the CPU loses communication with I/O networks (e.g., Profibus DP, Foundation Fieldbus, or AC 800M’s own S800 I/O). This results in a complete halt of control logic execution. In non-redundant systems, this causes immediate process shutdown. Even in redundant configurations, a base unit fault can trigger a switchover event that may destabilize sensitive processes if not managed properly.

Reliability Analysis and Common Failure Modes

Although the UAC389AE02 contains no active processing components, its role as a high-density interconnect platform makes it susceptible to long-term reliability issues, especially in harsh industrial environments.

Common failure modes include:

- Backplane connector wear or oxidation due to thermal cycling, leading to intermittent data errors or module misrecognition.

- PCB trace delamination or solder joint fatigue caused by vibration (common in compressor or turbine skids).

- Corrosion on power or ground planes in high-humidity environments, increasing resistance and causing voltage drops.

- Mechanical damage to mounting brackets or guide rails during maintenance, compromising module seating.

Design limitations include reliance on precise mechanical alignment—any warping of the chassis or base can prevent full connector engagement. Additionally, the unit offers minimal self-diagnostics; most faults appear only as “module not found” or “communication lost” alarms at the system level.

Preventive maintenance recommendations:

- Inspect backplane connectors annually for discoloration, debris, or bent pins.

- Verify secure mounting and chassis alignment during routine outages.

- Monitor system logs for recurring “I/O scan timeout” events that may indicate marginal base connectivity.

- Store spare units in static-safe, climate-controlled packaging to avoid latent damage.

ABB UAC389AE02 HIEE300888R0002

Lifecycle Status and Migration Strategy

ABB has discontinued the UAC389AE02 and transitioned support to newer AC 800M hardware platforms (e.g., PM86x-based controllers with updated carriers). While the AC 800M architecture remains supported, this specific base unit is no longer available as new from ABB. Continued use depends entirely on secondary-market availability, which carries risks of counterfeit parts, unknown usage history, or degraded internal components.

As an interim measure, facilities can:

- Secure tested spares from ABB-certified resellers with functional validation reports.

- Implement preventive replacement programs for units installed before 2012.

- Use system redundancy to tolerate single-point failures during critical operations.

For long-term sustainability, ABB recommends migrating to the latest AC 800M generation (e.g., PM866AK01 or PM867B) using current base units like UAC390AE01. This migration typically requires:

- Replacing the controller base and CPU module.

- Updating System 800xA software to a compatible version (e.g., 6.1 or higher).

- Retaining existing I/O modules and field wiring where possible.

- Recompiling and re-downloading control logic using Control Builder M.

While the migration involves engineering effort, it restores access to factory warranties, cybersecurity patches, and technical support. It also enables integration with modern IT/OT infrastructure via OPC UA, MQTT, and enterprise asset management systems. A phased approach—starting with non-critical controllers—allows organizations to manage risk while extending the life of their automation investment.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: