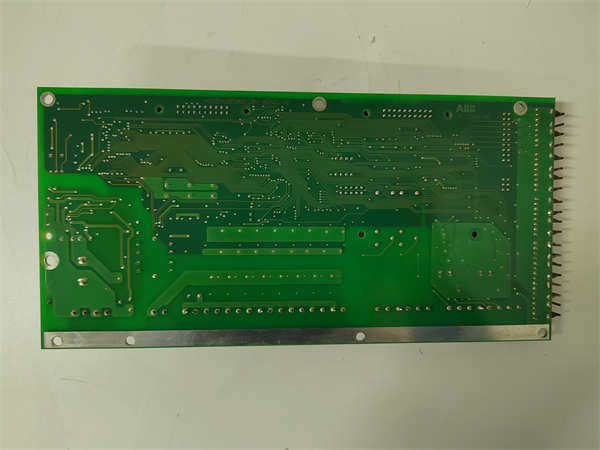

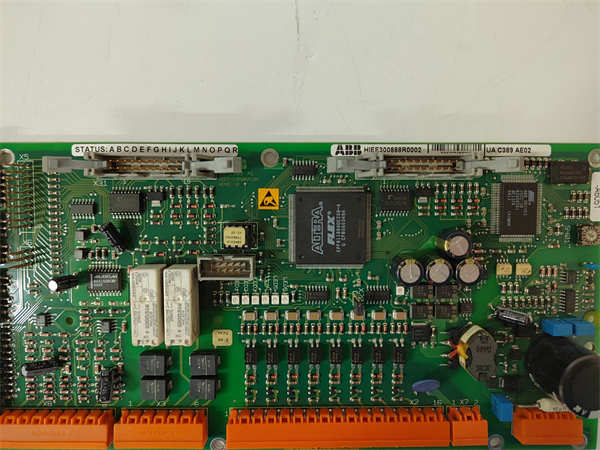

Description

Key Technical Specifications (for Spare Part Verification)

- Product Model: UAC389AE02

- Order Code: HIEE300888R0002

- Manufacturer: ABB Ltd.

- System Family: AC 800M (part of 800xA DCS platform)

- Module Type: Communication interface module (CIM)

- Protocol Support: PROFIBUS DP (Decentralized Periphery), configurable as Master or Slave

- Communication Speed: Up to 12 Mbps (selectable via configuration)

- Physical Interface: RS-485 via 9-pin D-sub connector (isolated)

- Backplane Connection: Proprietary AC 800M parallel bus (requires compatible I/O base)

- Diagnostic Features: LED indicators for Power, Module OK, PROFIBUS Activity, and Fault

- Redundancy: Supports redundant configuration with dual modules (requires proper 800xA engineering)

- Configuration Tool: Control Builder M (within 800xA Engineering Studio)

- Certification: CE, UL, IEC 61131-2 compliant

System Role and Downtime Impact

The UAC389AE02 serves as a critical bridge between the AC 800M controller and field-level devices using the PROFIBUS DP protocol—commonly found in legacy installations involving ABB or third-party variable frequency drives (VFDs), remote I/O stations (e.g., ET200M), smart valve positioners, and analyzers. In a typical refinery, chemical plant, or power facility, dozens of field devices may depend on a single UAC389AE02 module for real-time data exchange. If the module fails—due to hardware fault, configuration corruption, or communication timeout—all connected PROFIBUS devices become unreachable, leading to loss of control, forced manual operation, or automatic safety derating. In non-redundant configurations (still common in older systems), this results in immediate process disruption. Even in redundant setups, improper synchronization or outdated firmware can prevent seamless failover, extending recovery time.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the UAC389AE02 is vulnerable to several age-related failure mechanisms after 10–15 years of continuous operation. The most frequent issue is RS-485 transceiver degradation, often caused by repeated ground potential differences or surge events on long PROFIBUS trunks, leading to intermittent communication or complete link dropout. The isolated DC/DC converter powering the field interface can also fail due to capacitor aging, causing loss of signal isolation and potential backplane damage. Additionally, the module’s firmware image—stored in flash memory—can become corrupted if subjected to frequent power cycling without proper shutdown procedures, especially in unstable grid environments. Environmental factors such as high ambient temperature or dust ingress accelerate component stress. Recommended maintenance includes: verifying termination and shielding integrity on the PROFIBUS cable annually, monitoring bus diagnostics via 800xA for cyclic redundancy errors, inspecting module LEDs for abnormal behavior, and maintaining spares under controlled storage conditions (15–25°C, low humidity).

-

ABB UAC389AE02 HIEE300888R0002

Lifecycle Status and Migration Strategy

ABB has formally discontinued the UAC389AE02 (HIEE300888R0002), with no direct replacement offered in current AC 800M portfolios. Newer systems utilize Ethernet-based field connectivity (e.g., PROFINET via AC 800M CI874 or PN/PN couplers), reflecting the industry-wide shift away from serial fieldbuses. Continuing to rely on this obsolete module introduces significant operational and cybersecurity risks—particularly as PROFIBUS lacks modern authentication or encryption features. Secondary market units may be untested, mismatched in firmware version, or previously damaged. As a short-term mitigation, facilities should:

- Maintain at least one tested spare per critical application

- Archive original GSD files and Control Builder M configuration projects

- Verify PROFIBUS slave device compatibility before module replacement

For long-term sustainability, ABB recommends migrating to PROFINET-based communication using modern modules such as the CI874 (HIEE400040R0001) or integrating protocol gateways (e.g., HMS Anybus X-gateway) to bridge existing PROFIBUS segments to Ethernet/IP or PROFINET networks. This approach preserves legacy field devices while enabling integration with updated 800xA architectures, improved diagnostics, and enhanced network security. Full migration requires re-engineering communication topology, updating device descriptions, and re-commissioning I/O—but delivers greater bandwidth, reduced wiring, and alignment with IEC 62443 standards. Early collaboration with ABB or certified system integrators is essential to develop a cost-effective, phased transition plan aligned with plant modernization schedules.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: