Description

Key Technical Specifications (For Spare Parts Verification)

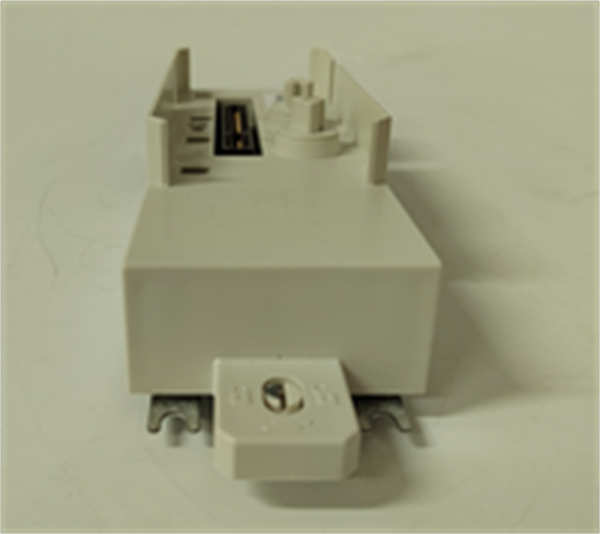

- Product Model: TP858 3BSE018138R1

- Manufacturer: ABB

- System Family: AC 800M (part of 800xA architecture)

- ABB Order Code: 3BSE018138R1

- Display Type: Monochrome STN LCD, 5.7 inches

- Resolution: 320 × 240 pixels

- Touch Technology: 4-wire resistive touchscreen

- Communication Interface: Proprietary serial link to AC 800M CPU (via backplane or dedicated cable)

- Compatible CPUs: PM860, PM861, PM864, PM865 (AC 800M series)

- Power Supply: 24 V DC (typically sourced from CPU rack or external PSU)

- Mounting: Panel-mount with IP65 front protection (when properly sealed)

- Operating Temperature: 0°C to +55°C

- Firmware Requirement: Must match version deployed in Control Builder M project

System Role and Downtime Impact

The TP858 3BSE018138R1 functions as a localized operator station directly integrated with ABB AC 800M control systems, frequently deployed in water pumping stations, auxiliary power skids, or small industrial cells where a full 800xA workstation is impractical. It enables field personnel to view real-time process graphics, acknowledge alarms, adjust setpoints, and initiate manual sequences without relying on central control room access. If this unit fails—due to screen blanking, unresponsive touch, or communication loss—on-site operators lose critical situational awareness and intervention capability. In regulated environments (e.g., water treatment), this may violate operational compliance requirements that mandate local HMI access, potentially forcing a controlled shutdown or manual bypass procedures until restored.

Reliability Analysis and Common Failure Modes

After 10–15 years of continuous operation, the TP858 3BSE018138R1 exhibits well-documented aging issues. The most prevalent failure is LCD panel degradation, including fading contrast, ghosting, vertical lines, or complete loss of backlight (in later revisions), making the display unreadable under plant lighting. Second, the resistive touchscreen suffers from mechanical wear, leading to calibration drift, dead zones, or erratic cursor jumps—particularly problematic for precise button presses in alarm management. Third, internal power supply capacitors degrade over time, causing spontaneous reboots, failure to power on, or unstable communication with the CPU.

A notable design constraint is its dependency on a direct, low-level serial protocol with no Ethernet fallback or remote diagnostics. Additionally, firmware updates require physical connection via ABB’s proprietary tools, and the monochrome display lacks modern visual indicators for network or security status.

For preventive maintenance, routinely verify screen legibility and touch accuracy across all screen regions. Monitor CPU diagnostic logs for “LOU communication lost” events. Ensure the unit is mounted away from direct sunlight and excessive heat sources. During planned outages, inspect rear connectors for corrosion and clean the touchscreen surface with non-abrasive, anti-static wipes.

TP858 3BSE018138R1 ABB

Lifecycle Status and Migration Strategy

ABB has formally discontinued the TP858 series, including part number 3BSE018138R1, as part of its transition toward modern, networked HMI solutions. No new units are manufactured, and official repair or technical support is no longer available. Continued operation relies on dwindling spare inventory, posing increasing risk to system availability.

As a short-term mitigation, secure at least one tested and verified spare unit. Prioritize vendors who provide functional test reports—including touchscreen calibration and CPU handshake validation—and avoid untested surplus stock.

For long-term sustainability, ABB’s recommended migration path is to replace the TP858 with a panel-mounted industrial PC (IPC) running System 800xA Compact HMI or Workplace Lite, connected via Ethernet to the AC 800M CPU using OPC UA or Modbus TCP. Alternatively, if the CPU firmware supports it, enable the built-in web server to allow browser-based access from any ruggedized tablet or handheld device.

This transition typically involves:

- Installing a new panel PC with appropriate environmental rating (e.g., IP65)

- Recreating or exporting existing graphics to a web-compatible format

- Configuring secure user authentication and role-based access

- Updating network segmentation and cybersecurity policies

While requiring initial engineering effort, this approach delivers color displays, multi-touch support, remote diagnostics, and alignment with current IT/OT convergence standards. A phased replacement—starting with units showing early signs of failure—is the most operationally sound strategy for maintaining continuity in legacy ABB installations.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: