Description

Technical Specifications (For Spare Parts Verification)

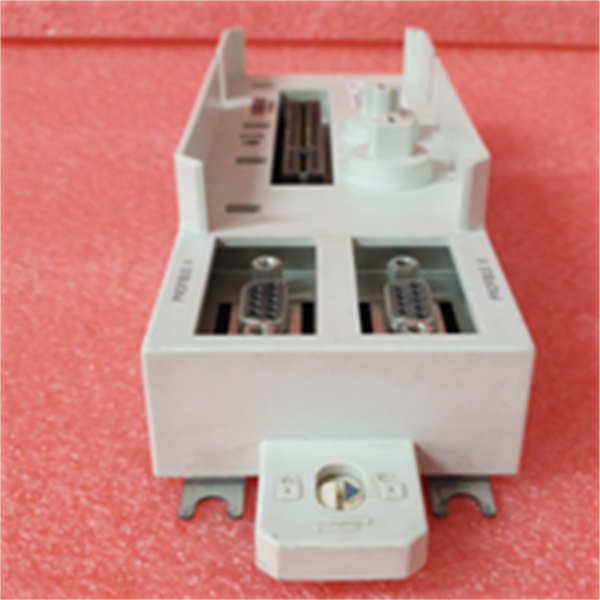

- Product Model: TP854 3BSE025349R1

- Manufacturer: ABB

- System Platform: AC 800M within ABB 800xA distributed control system

- Type: Termination panel / base unit (non-intelligent)

- Mounting: DIN rail (TS-35/7.5)

- Compatible I/O Modules: Standard 800xA I/O modules (e.g., AI810, DI810, DO810, etc.)

- Field Wiring Terminals: Screw-type or spring-clamp terminals (depending on revision), rated for 24 VDC / 250 VAC

- Power Distribution: Provides +24 VDC, GND, and logic power rails from backplane to I/O module

- Redundancy Support: Yes – used in pairs for redundant I/O configurations with RP854 redundancy panels

- Backplane Interface: Connects to CI854 communication module via ribbon cable or direct carrier

- Dimensions: Approx. 160 mm (W) × 120 mm (H) × 80 mm (D)

- Operating Temperature: 0°C to 60°C

System Role and Downtime Impact

The TP854 is a passive but essential component in legacy ABB AC 800M I/O stations. It acts as the bridge between field instrumentation wiring (from junction boxes or marshalling cabinets) and the intelligent I/O modules that process signals for the controller. Each TP854 typically hosts one I/O card handling 8–16 analog or digital channels critical to process control—such as temperature inputs, valve commands, or motor status feedback.

While the TP854 itself contains no electronics, its integrity directly affects system reliability. Loose terminals, corroded contacts, or cracked housing can lead to high-resistance connections, causing signal drift (in analog loops) or flickering states (in digital inputs). In redundant systems, a faulty TP854 may prevent proper switchover during primary module failure, defeating the purpose of redundancy. Replacement requires de-energizing the I/O station, removing all field wires, and re-terminating—a time-consuming task that often extends unplanned downtime during troubleshooting.

Reliability Analysis and Common Failure Modes

As a mechanical-electrical interface, the TP854 is prone to environmental and operational wear rather than electronic failure:

- Terminal screw loosening: Vibration from nearby pumps or compressors can gradually loosen screw terminals, increasing contact resistance and generating heat under load.

- Corrosion on copper traces: In humid or corrosive environments (e.g., coastal plants, chemical facilities), oxidation of internal busbars can degrade power delivery to the I/O module.

- Plastic housing embrittlement: Prolonged exposure to UV (if near windows) or high ambient temperatures causes the polycarbonate housing to crack, risking short circuits or unsafe access to live parts.

- Backplane connector wear: Repeated insertion/removal of I/O modules fatigues the female contacts, leading to poor mating and intermittent communication errors.

A key vulnerability is that failures are often invisible—no LEDs or diagnostics exist on the TP854 itself. Issues are only detected when the connected I/O module reports erratic behavior or channel faults.

Preventive maintenance should include:

- Torque-checking all field terminals during scheduled outages (per ABB spec: ~0.6 Nm for M3 screws)

- Inspecting for discoloration or carbon tracking near high-current terminals

- Applying anti-oxidant compound on copper surfaces in high-humidity areas

- Labeling and documenting wire positions before any removal to avoid cross-wiring

ABB TP854 3BSE025349R1

Lifecycle Status and Migration Strategy

ABB has phased out the TP854 as part of its shift toward Electronic Marshalling and compact I/O platforms (e.g., ABB Ability™ System 800xA with Compact I/O or Remote I/O over PROFINET). The TP854 is no longer listed in current price books, and new units cannot be sourced from ABB.

Immediate actions should focus on preserving existing infrastructure:

- Audit all installed TP854 units and replace those showing physical damage

- Maintain a spare pool with intact terminals and clean connectors

- Use thermal imaging during operation to detect abnormal heating at termination points

For long-term sustainability, ABB recommends migrating to modern I/O architectures:

- Option 1: Transition to Compact I/O (e.g., TU85x series with integrated terminals), which reduces footprint and improves diagnostic coverage.

- Option 2: Implement Remote I/O over Ethernet (e.g., using ABB’s IO4000 or third-party PROFINET devices), eliminating centralized termination panels entirely and enabling distributed I/O placement closer to field devices.

Both paths reduce wiring complexity, improve signal integrity, and restore access to manufacturer support. While the TP854 remains functional today, its obsolescence makes proactive planning essential to avoid future operational disruption.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: