Description

Technical Specifications (For Spare Part Verification)

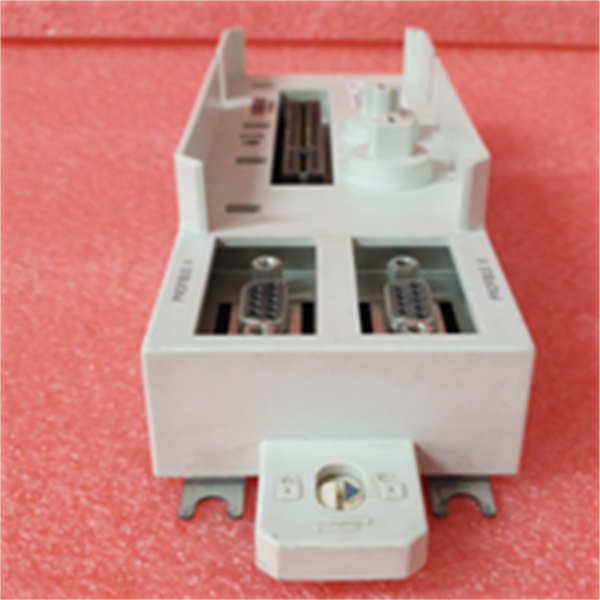

- Product Model: TP854

- Manufacturer: ABB

- Order Code: 3BSE025349R1

- System Family: ABB AC 800M automation platform

- Compatible Module: CI854 PROFIBUS DP communication interface

- Mounting Type: DIN rail mounted termination panel

- Connector Type: Screw terminals for field-side PROFIBUS cabling

- Bus Interface: RS-485 (PROFIBUS DP compliant)

- Power Supply: Powered via backplane from connected I/O module; no independent power input

- Diagnostic Indicators: LED status indicators for bus activity and fault (when used with CI854)

- Environmental Rating: Designed for industrial control cabinet use (typically 0–55°C ambient)

System Role and Downtime Impact

The TP854 serves as the field-wiring interface for the CI854 PROFIBUS DP master/slave module within ABB’s AC 800M distributed control architecture. It does not process data but provides robust, shielded termination for up to two PROFIBUS segments, ensuring signal integrity across remote I/O networks. In typical deployments—such as pulp & paper, power generation, or mining—it connects dozens of remote I/O devices (e.g., motor starters, valve positioners, sensors). Failure of the TP854 (e.g., due to terminal corrosion, internal trace damage, or connector fatigue) can cause complete loss of communication on one or both PROFIBUS lines, leading to loss of visibility and control over entire subsystems. Since redundancy is not always implemented at the termination level, such a failure often results in partial or full plant shutdown until the unit is replaced.

Reliability Analysis and Common Failure Modes

Although the TP854 contains no active electronics, it remains vulnerable to environmental and mechanical degradation. The most frequent issues arise from oxidation or loosening of screw terminals due to thermal cycling or vibration, causing intermittent bus faults that are difficult to diagnose. In high-humidity environments, moisture ingress can lead to creepage or short circuits between adjacent terminals. Additionally, repeated plugging/unplugging of the backplane connector during maintenance may wear the contact pins, increasing resistance and signal reflection on the PROFIBUS line. The unit lacks surge protection, making it susceptible to ground potential differences or induced transients from nearby heavy equipment. For preventive maintenance, technicians should periodically torque-check all field terminals, inspect for discoloration or arcing marks, verify shield grounding continuity, and ensure the unit is securely seated on the DIN rail with proper strain relief on field cables.

TP854 3BSE025349R1 ABB

Lifecycle Status and Migration Strategy

ABB has officially discontinued the TP854 (3BSE025349R1) as part of the broader phase-out of legacy AC 800M I/O components. No direct replacement is offered, and official support is restricted to existing service contracts. Continued reliance on this module poses escalating risks: spare units are increasingly scarce, counterfeit or untested parts may enter the supply chain, and system documentation may no longer be updated. As an interim measure, facilities can implement rigorous spares pooling, perform visual and electrical inspections during outages, or retrofit external PROFIBUS repeaters with built-in diagnostics to isolate faults. For strategic migration, ABB recommends upgrading to the newer AC 800M I/O modules based on PROFINET or redundant Ethernet (e.g., using CI874 or CI864 with modern termination units like TP874). This transition typically requires re-engineering the I/O topology, updating control software in Automation Builder, and re-commissioning field devices—but significantly enhances cybersecurity, diagnostics, and long-term supportability. Planning this migration during scheduled turnarounds is advisable to mitigate unplanned downtime risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: