Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: TC520 3BSE001449R1

- Manufacturer: ABB

- System Platform: ABB AC 800M (part of System 800xA architecture)

- Compatible Modules: Standard 8-channel I/O modules including DI810, DO810, AI810, AO810

- Terminal Type: Screw-clamp, front-accessible, max conductor size 2.5 mm² (AWG 14)

- Backplane Connector: 44-pin DIN 41612 female connector (Type C)

- Mechanical Fixing: Snap-on DIN rail mount with module retention latch

- Number of Terminals: 18 (for 8 I/O channels + common/power/ground)

- Operating Temperature: 0°C to +55°C

- Physical Labeling: Must include “TC520” and “3BSE001449R1”; revision code (e.g., Rev A) may affect compatibility with certain module batches

System Role and Downtime Impact

The TC520 3BSE001449R1 is a passive but mission-critical component in ABB AC 800M I/O stations. It does not process signals but enables the secure mounting of I/O modules and provides the field wiring interface. In practice, every digital or analog I/O point in an AC 800M system depends on a functional TC520 base. If a TC520 fails—due to cracked housing, stripped terminals, or damaged backplane pins—the associated I/O module becomes unusable. During a module failure event, the absence of a spare TC520 prevents recovery, even if the replacement module is available. In continuous processes such as power generation, water treatment, or chemical manufacturing, this can delay restoration by days or weeks, leading to extended downtime, manual operation risks, or regulatory non-compliance.

Reliability Analysis and Common Failure Modes

As a mechanical-electrical interface, the TC520 is prone to wear and environmental degradation despite having no active electronics. The most common failure mode is mechanical fatigue: repeated insertion and removal of I/O modules can deform the plastic latch or wear the guide rails, resulting in poor module seating and intermittent backplane contact. Terminal screws may strip due to over-torquing during maintenance, making secure wiring impossible. In humid or corrosive environments, terminal blocks can develop oxidation or galvanic corrosion (especially with mixed-metal conductors), increasing contact resistance and causing signal dropouts that mimic sensor or module faults. Additionally, the polycarbonate housing can become brittle over time, particularly when exposed to UV light or cleaning solvents, leading to cracks during handling.

Preventive maintenance should include visual inspection of the latch mechanism, torque verification of terminal screws (~0.6 Nm), and checking for discoloration or pitting on metal contacts. Technicians should avoid forcing modules into worn bases, as this can damage the backplane connector. Since the unit has no diagnostics, functional verification requires installing a known-good I/O module and confirming communication with the controller.

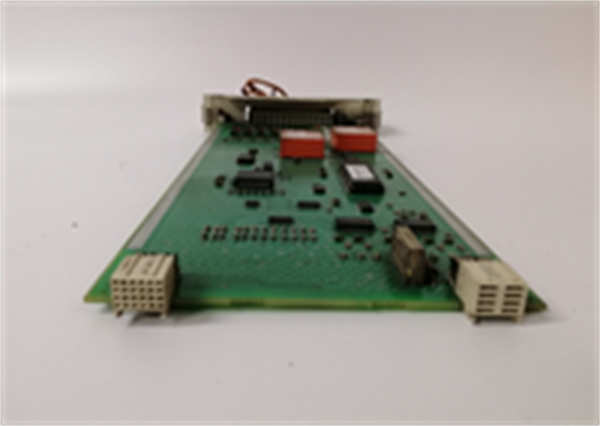

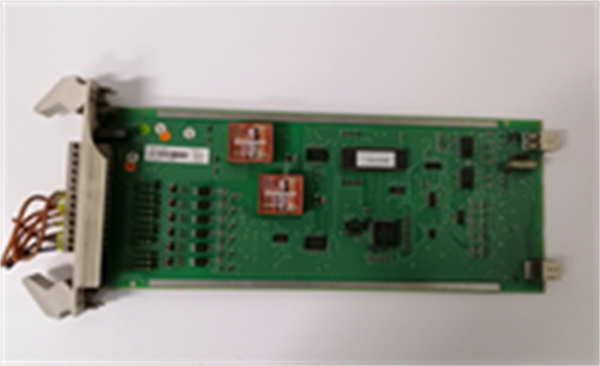

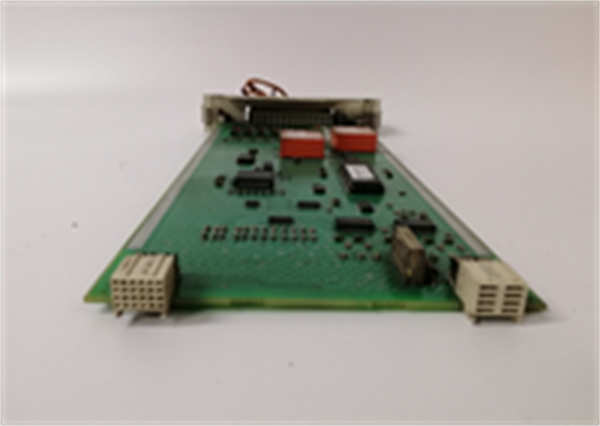

ABB TC520 3BSE001449R1

Lifecycle Status and Migration Strategy

ABB has officially discontinued the TC520 3BSE001449R1 as part of the phase-out of first-generation AC 800M I/O hardware. No new units are manufactured, and ABB no longer stocks replacements or provides technical support for compatibility issues. Continued use carries significant risk: inventory is finite, pricing is unstable, and used units may have hidden mechanical damage.

Short-term mitigation includes auditing existing spares, salvaging units from decommissioned cabinets, or sourcing from specialized obsolescence vendors who perform mechanical integrity checks. However, these options do not eliminate long-term vulnerability.

ABB’s recommended migration path is to transition to the AC 800M Next Generation I/O platform, which uses the TB840 (3BSE042288R1) or TB850 series terminal bases. This upgrade requires:

- Replacing all TC520 bases with TB840/TB850 units

- Installing compatible next-gen I/O modules (e.g., DI840 instead of DI810)

- Updating hardware configuration in Control Builder M

- Re-terminating field wiring (though cabinet layout often remains unchanged)

While this involves upfront engineering, it restores access to factory support, improves diagnostic visibility, and extends system life expectancy. For facilities unable to execute full migration, maintaining a minimum reserve of two verified TC520 units—each inspected for latch function, terminal integrity, and backplane pin alignment—is the only practical contingency to ensure rapid recovery during I/O module failures.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: