Description

Technical Specifications (For Spare Part Verification)

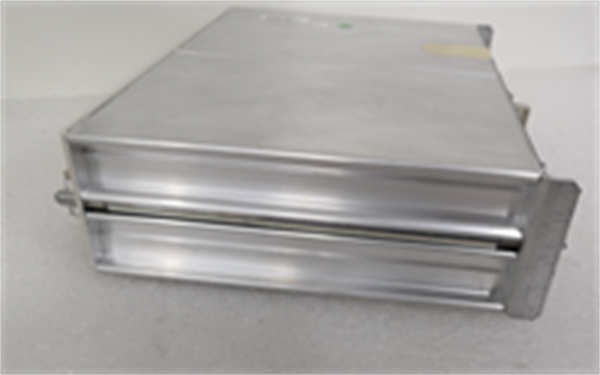

- Product Model: TC512V1

- ABB Order Code: 3BSE018059R1

- Manufacturer: ABB

- System Platform: AC 800M (part of ABB’s 800xA automation architecture)

- Module Type: PROFIBUS DP Master communication interface

- Bus Protocol: PROFIBUS DP (Class 1 and Class 2 services supported)

- Communication Speed: Configurable from 9.6 kbps to 12 Mbps

- Max Slave Devices: Up to 126 per segment (depending on configuration and GSD files)

- Electrical Interface: RS-485 via 9-pin D-SUB connector (isolated)

- Isolation Voltage: 500 V RMS between field bus and system ground

- Redundancy Support: Supported in redundant AC 800M configurations (hot standby)

- Physical Form: Standard AC 800M module, front-panel LEDs for PWR, RUN, COM, and BF (bus fault)

System Role and Downtime Impact

The TC512V1 is a critical communication gateway in ABB’s AC 800M-based control systems, commonly deployed in power plants, water treatment facilities, and industrial process lines. It allows the AC 800M controller to function as a PROFIBUS DP master, directly polling and controlling remote I/O stations (e.g., ABB CI854-based racks), variable frequency drives (VFDs), valve positioners, and smart transmitters that support PROFIBUS PA/DP.

If this module fails or loses bus synchronization, all connected PROFIBUS devices become unreachable. In a water pumping station, this could mean loss of motor status and flow control; in a boiler system, it may disable burner management or feedwater regulation. Because many of these devices are not hardwired to the main controller, their data disappears entirely from the 800xA operator environment, potentially triggering alarms or safety interlocks. In non-redundant installations, a single TC512V1 failure can cripple an entire process unit, leading to unplanned downtime.

Reliability Analysis and Common Failure Modes

The TC512V1 integrates high-speed serial communication circuitry that is sensitive to long-term electrical stress. The most common failure point is the RS-485 transceiver IC, which can degrade due to repeated exposure to ground potential differences, ESD events, or lightning-induced surges—especially in outdoor or poorly grounded installations. This often manifests as intermittent “bus fault” (BF LED blinking) or complete communication dropout.

Another vulnerability lies in the isolation barrier components (optocouplers and DC/DC converters). Over time, these can lose efficiency, leading to signal distortion or power instability on the field side. Additionally, the module’s firmware, stored in non-volatile memory, can become corrupted after years of operation or during unclean power cycles, causing boot failures or incorrect PROFIBUS parameter loading.

Preventive maintenance should include: inspecting PROFIBUS cabling for proper termination (120 Ω at both ends), shield grounding at one point only, and absence of spur lines; monitoring for cyclic redundancy check (CRC) errors in 800xA diagnostics; and verifying bus voltage levels (typically 3–5 V peak-to-peak differential). Any spare TC512V1 must be tested with a live PROFIBUS network—including at least two slave devices—at multiple baud rates before being accepted into inventory.

ABB TC512V1 3BSE018059R1

Lifecycle Status and Migration Strategy

ABB has officially discontinued the TC512V1 as part of its transition away from legacy fieldbus modules toward Ethernet-based communication. While the AC 800M platform remains supported, newer projects use modules like the TK851 (PROFINET) or TB510 (Modbus TCP/EtherNet/IP). The TC512V1 is no longer produced, and ABB provides only limited technical support under legacy agreements.

Continued reliance on this module carries significant risk: authentic spares are dwindling, and counterfeit units may lack proper isolation or firmware integrity. Firmware mismatches can also cause compatibility issues with updated 800xA engineering tools.

Short-term mitigation includes securing only fully tested, traceable units and maintaining a backup configuration file (.prj or .gcf) that includes the exact GSD revisions used.

For long-term sustainability, ABB recommends migrating PROFIBUS segments to PROFINET using the TK851 communication module. This requires replacing slave devices or using PROFINET-to-PROFIBUS gateways (e.g., ABB TB540) for brownfield integration. Alternatively, consolidating legacy field devices onto a modern remote I/O platform (e.g., ABB Ability™ Smart Sensor with wireless gateway) reduces bus complexity. While migration demands engineering effort, it improves cybersecurity, diagnostics, and future spare parts availability. Facilities planning operational life beyond 2030 should prioritize this transition to maintain system reliability and compliance with evolving industrial networking standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: