Description

Technical Specifications (For Spare Part Verification)

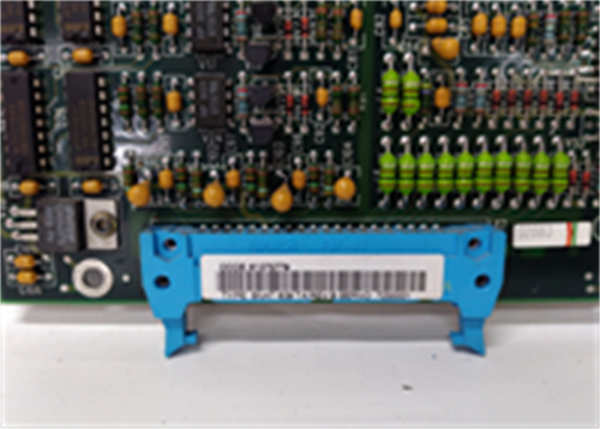

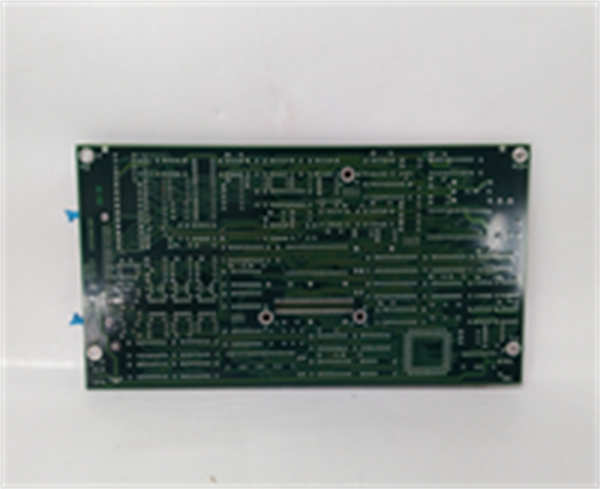

- Product Model: SNAT609TAI

- Manufacturer: ABB

- System Platform: AC 800M (part of ABB 800xA distributed control system)

- Module Type: Analog input module, temperature-specific

- Input Channels: 8 differential inputs

- Supported Sensor Types: Pt100, Pt1000, Ni100 RTDs; J, K, T, E, N, R, S thermocouples

- Input Resolution: 16-bit A/D conversion

- Accuracy: ±0.1% of full scale (typical for RTD), ±0.25% for thermocouples (with cold junction compensation)

- Isolation: Channel-to-bus isolation (500 V RMS)

- Backplane Interface: Proprietary AC 800M I/O bus

- Physical Form: Standard AC 800M module, front-panel status LEDs, removable terminal block

System Role and Downtime Impact

The SNAT609TAI is installed in the I/O chassis of an ABB AC 800M controller and serves as the primary interface for temperature sensors in process-critical applications—such as reactor monitoring, boiler feedwater control, or compressor bearing protection. Unlike generic analog inputs, this module includes built-in linearization, cold junction compensation, and sensor diagnostics tailored for thermal measurements.

If the module fails or provides inaccurate data, the control system may misinterpret process conditions. In a distillation column, for example, a faulty reading could cause overheating or flooding. In safety-related loops (e.g., turbine exhaust temperature), degraded signal integrity might prevent a timely trip, violating functional safety requirements. Because temperature is often a key variable in regulatory compliance (e.g., EPA, API standards), loss of reliable measurement can force operational curtailment or shutdown.

Reliability Analysis and Common Failure Modes

Despite its industrial-grade design, the SNAT609TAI is vulnerable to long-term degradation:

- Cold junction compensation (CJC) sensor drift: The onboard temperature sensor used for thermocouple reference can drift over time, especially in high-ambient environments, leading to systematic offset errors.

- Reference voltage instability: Aging of precision voltage references affects all channels simultaneously, causing gain errors that are difficult to detect without calibration.

- Terminal block corrosion: In humid or corrosive plants (e.g., offshore, pulp & paper), oxidation on screw terminals increases contact resistance, inducing noise or open-circuit faults.

- Power supply ripple sensitivity: Degraded internal filtering capacitors make the module susceptible to noise from shared 24 V DC supplies, manifesting as erratic readings or channel dropouts.

Recommended maintenance practices include:

- Performing annual calibration using certified temperature simulators across multiple points (e.g., 0°C, 100°C, 300°C)

- Verifying CJC accuracy by comparing ambient readings with a calibrated thermometer

- Inspecting terminal tightness and applying anti-oxidant compound in harsh environments

- Monitoring 800xA diagnostic logs for “INPUT FAULT”, “SENSOR ERROR”, or “DIAGNOSTIC WARNING”

SNAT609TAI ABB

Lifecycle Status and Migration Strategy

ABB has officially discontinued the SNAT609TAI as part of its transition toward unified I/O platforms. It is no longer listed in current catalogs, and technical support is restricted to legacy service agreements. Continuing to operate systems dependent on this module carries significant risk: genuine spares are scarce, prices have escalated, and uncalibrated units from the gray market may compromise measurement integrity.

Short-term mitigation includes securing only traceable, factory-tested units and maintaining a master calibration record for each installed module.

The recommended migration path is to replace the SNAT609TAI with the AI810 or AI815 analog input modules in combination with external temperature transmitters (e.g., ABB TTF series). While this adds a layer of hardware, it offers superior diagnostics, HART communication, and compatibility with modern 800xA features like asset management and predictive maintenance. Alternatively, for new retrofits, ABB promotes the AC 800M PM86x CPU with TB850/TB851 baseplates supporting AI880A high-density analog modules, which consolidate multiple functions into fewer slots.

Migration requires re-engineering the control logic in Control Builder M and updating I/O tags in System 800xA, but preserves the core application structure. ABB provides migration engineering services, including configuration conversion, FAT, and site commissioning. For facilities planning operation beyond 2030, this upgrade is essential to ensure measurement reliability, regulatory compliance, and long-term supportability.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: