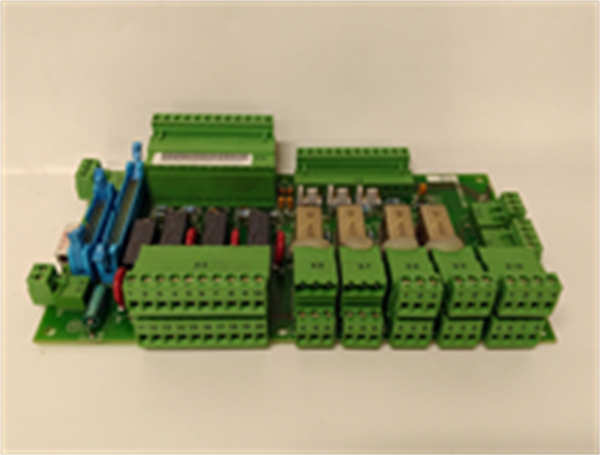

Description

Technical Specifications (For Spare Parts Verification)

- Product Model: SNAT602TAC

- Manufacturer: ABB

- Associated System: SACE Tmax T6 / T7 Low-Voltage Circuit Breakers

- Function Type: Shunt Trip Actuator (Remote Trip Coil)

- Control Voltage Rating: 24–250 V AC/DC (universal coil)

- Mounting Position: Left-side accessory compartment on Tmax frame

- Mechanical Interface: Compatible with Tmax T6N, T6S, T7S frames (630–1600 A)

- Electrical Connection: 2-terminal screw clamp (max 2.5 mm² wire)

- Operating Temperature: -25°C to +70°C

- Compliance: IEC/EN 60947-2, CE marked

System Role and Downtime Impact

The SNAT602TAC is an electromechanical shunt trip accessory installed on ABB SACE Tmax circuit breakers in medium-to-large industrial power distribution panels. It allows external control systems—such as fire alarm panels, PLC safety relays, or SCADA commands—to remotely open the breaker during emergencies or process faults. If this module fails (e.g., coil burnout or mechanical jam), the breaker remains “locked” in the closed position, rendering automated or manual remote tripping impossible. In critical applications—such as data center UPS feeds, chemical plant motor control centers, or hospital backup power systems—this single point of failure can prevent safe isolation during faults, potentially leading to equipment damage, regulatory non-compliance, or extended unplanned downtime during maintenance.

Reliability Analysis and Common Failure Modes

Although robust in design, the SNAT602TAC exhibits predictable aging patterns due to its electromechanical nature and operational environment. The most frequent failure mode is coil burnout, typically caused by prolonged energization beyond the recommended 100 ms pulse duration—often due to faulty control logic or sticking relay contacts in upstream safety circuits. A secondary issue is mechanical binding of the trip lever, resulting from dust ingress, corrosion in humid environments, or lack of periodic exercise in infrequently operated systems.

The inherent weakness lies in its dependency on a single-point actuation mechanism with no self-diagnostics. Unlike modern electronic trip units, it provides no feedback on coil health or operational readiness. Additionally, the terminal block is prone to loosening over time due to thermal cycling, increasing contact resistance and risk of overheating.

As a maintenance best practice, facilities should implement a preventive verification program: annually test remote trip functionality under load (where safe), inspect terminals for discoloration or oxidation, and verify control voltage waveform integrity using an oscilloscope to ensure clean, short-duration pulses. Units showing delayed response (>200 ms) or requiring repeated actuation attempts should be preemptively replaced.

SNAT602TAC ABB

Lifecycle Status and Migration Strategy

ABB officially discontinued the SNAT602TAC as part of its transition from the legacy Tmax platform to the Tmax XT and Emax 2 families. No direct “drop-in” replacement exists, and continued use carries significant risks: dwindling global inventory, absence of factory support, and increasing counterfeit parts in the gray market.

For facilities unable to execute a full panel upgrade immediately, two interim strategies are viable:

- Strategic Stockpiling: Acquire verified genuine units now to cover 5–7 years of operational need.

- Functional Retrofit: Replace only the breaker frame with a Tmax XT model (e.g., T7S XT) that supports modern shunt trip accessories (e.g., ST/XT series), which offer improved durability and optional status feedback contacts.

The long-term migration path endorsed by ABB is a phased upgrade to the Tmax XT platform. This requires replacing the entire breaker but retains the same physical dimensions and busbar interfaces in most cases, minimizing panel modifications. While re-engineering of control wiring may be needed, the new system gains compatibility with ABB’s Ability™ EDCS for digital monitoring, significantly enhancing asset visibility and predictive maintenance capabilities. Engineering services should include arc flash reassessment and coordination study updates as part of the migration scope.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: