Description

Key Technical Specifications (For Spare Parts Verification)

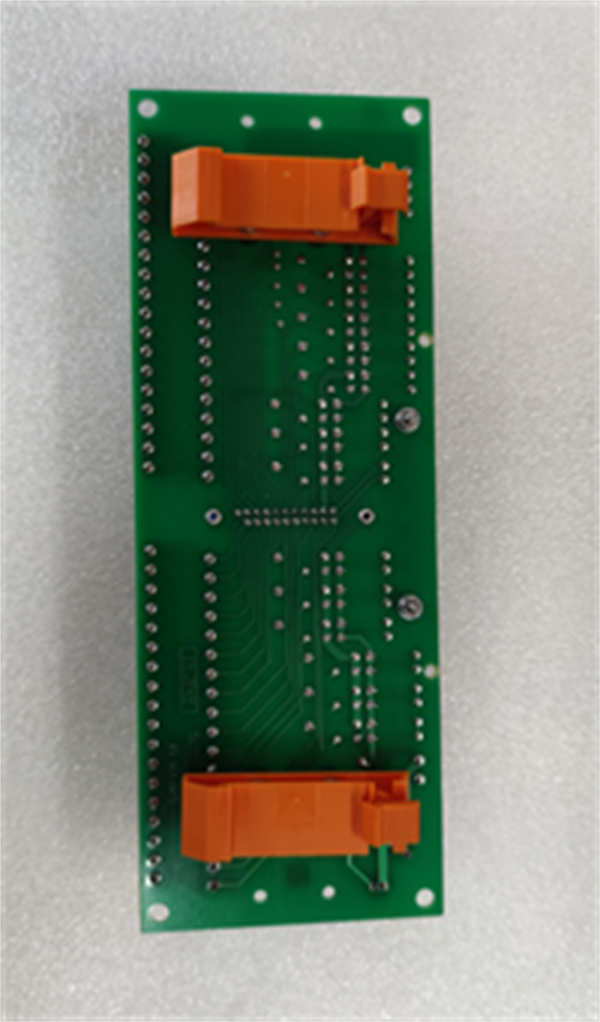

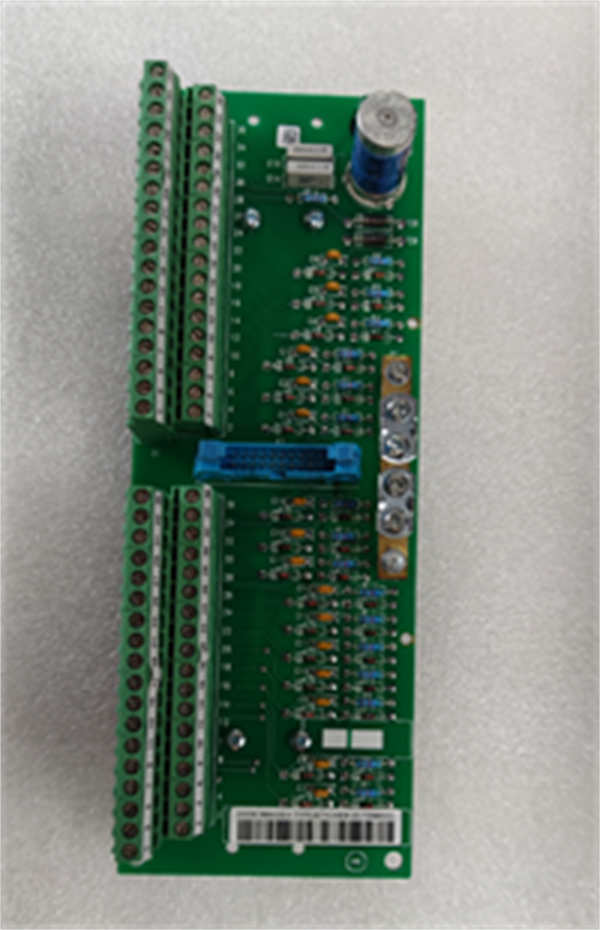

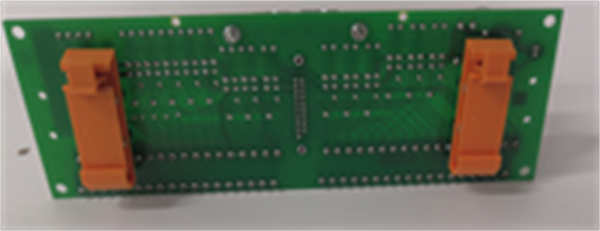

- Product Model: SCYC55830

- Drawing Number: 58063282A

- Manufacturer: ABB

- System Family: MasterPiece 200 / MasterPiece 300 (MP200/MP300)

- Board Type: Communication interface or I/O backplane adapter (exact function varies by system configuration)

- Physical Form: Standard MP300 plug-in card, approx. 220 mm × 160 mm

- Connector Type: Dual-edge gold-plated connector compatible with MP300 backplane

- Power Requirement: Supplied via backplane (+5 VDC, ±12 VDC rails)

- Mounting: Vertical insertion into MP300 chassis slot

- Indicators: Typically includes LED status indicators for power and activity

- Compatibility: Requires MP300 CPU (e.g., SCYC51000) and matching power supply (e.g., SCYC55000 series)

System Role and Downtime Impact

The SCYC55830 serves as a critical internal interface within the ABB MasterPiece 300 controller chassis. Depending on the system configuration, it may function as a remote I/O link driver, a serial communication gateway (e.g., to MODBUS or PROFIBUS), or a backplane signal conditioner for analog/digital modules. In operational plants—such as hydroelectric stations or paper mills still running MP300 systems—this board is often part of the core control loop infrastructure. If it fails, the result is typically an immediate loss of I/O communication, causing all connected field devices (valves, sensors, motors) to go offline. Since MasterPiece systems lack modern redundancy in most legacy deployments, this single-point failure usually forces a full process halt until the board is replaced. Recovery time can extend to days if a verified spare is not immediately available.

Reliability Analysis and Common Failure Modes

The SCYC55830, like most electronics from the 1990s, suffers primarily from electrolytic capacitor aging. These components dry out over time, leading to power rail instability, intermittent resets, or complete board malfunction. A secondary but critical failure mode is corrosion at the edge connector, caused by decades of thermal cycling and environmental humidity, resulting in poor contact with the backplane and erratic communication errors.

The board’s design lacks modern protection features: it is sensitive to power supply transients and offers no self-diagnostics, making fault isolation difficult without spare hardware for swap testing. Additionally, the absence of conformal coating in many production batches leaves traces vulnerable to sulfur-induced silver migration in industrial atmospheres.

Maintenance recommendations include: performing annual visual inspections for bulging capacitors or white residue (electrolyte leakage), cleaning the edge connector with contact enhancer during scheduled outages, verifying stable backplane voltages under load, and maintaining at least one tested spare in climate-controlled storage. Functional validation should be conducted using a known-good MP300 test rack before installation in live systems.

ABB SCYC55830 58063282A

Lifecycle Status and Migration Strategy

ABB officially ended support for the entire MasterPiece 200/300 platform over two decades ago. No new units are manufactured, and original documentation is archived. Continued operation carries significant risk: spare parts are irreplaceable once depleted, and system vulnerabilities cannot be patched. Regulatory audits under functional safety standards (e.g., IEC 61511) increasingly question the use of unsupported control hardware.

As a short-term mitigation, facilities may source and functionally test surplus boards, or engage specialized third-party repair services for component-level refurbishment—though long-term reliability remains uncertain.

The definitive solution is migration to a modern ABB platform. ABB recommends transitioning to the AC 800M controller within the System 800xA architecture. This requires full re-engineering: new I/O cabinets, updated logic programming (conversion from MasterPiece Ladder to Structured Text in Control Builder M), and integration with modern HMI/SCADA. While capital-intensive, this path restores access to cybersecurity updates, remote diagnostics, and lifecycle support. For budget-constrained sites, hybrid approaches—such as wrapping the MP300 in a protocol gateway to feed data to a supervisory layer—can extend life temporarily but do not eliminate core obsolescence risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: