Description

Key Technical Specifications (For Spare Parts Verification)

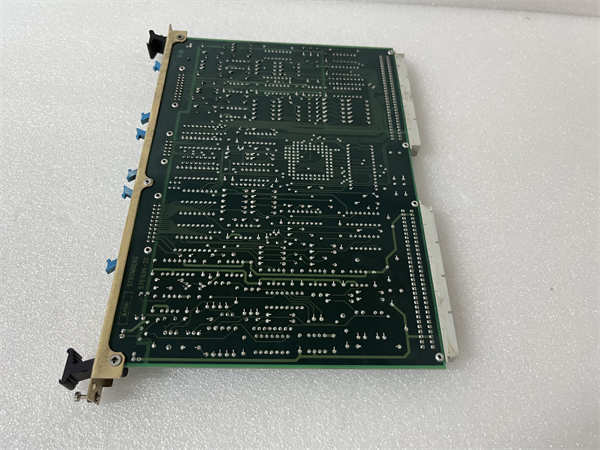

- Product Model: SCYC51020

- Manufacturer: ABB

- System Family: SATT 190 Distributed Control System (DCS)

- Processor Type: Motorola 68030-based industrial CPU

- Memory: Onboard RAM (typically 2–4 MB), backed by lithium battery; program stored in EPROM modules

- I/O Capacity: Supports up to 2,048 I/O points via remote I/O subsystems (e.g., SYCI/SYAI modules)

- Communication Interfaces: Dual redundant SATT Fieldbus (proprietary token-passing network) for I/O and peer-to-peer communication

- Redundancy: Supports 1:1 hot standby configuration with synchronization via dedicated link

- Power Requirement: +5 VDC and ±12 VDC supplied via backplane in SYMP cabinet

- Mounting: Installed in standard SYMP processor rack (3U height, 19″ width)

- Battery Backup: Contains internal lithium battery (typically 3.6 V) for RAM retention during power loss

System Role and Downtime Impact

The SCYC51020 serves as the brain of the SATT 190 DCS, commonly deployed in power generation, water treatment, and industrial process facilities from the late 1980s through the 1990s. It continuously executes ladder logic or function block programs, scans remote I/O racks, and communicates real-time data to operator consoles (e.g., SYOS stations). If this CPU fails—due to memory corruption, battery depletion, or hardware fault—the entire control loop for its assigned process area collapses. In non-redundant configurations, this forces operators into manual mode or triggers a controlled shutdown. Given the age of these systems, many sites lack robust manual fallback procedures, making CPU failure a high-consequence event with potential safety and environmental implications.

Reliability Analysis and Common Failure Modes

Despite rugged industrial design, the SCYC51020 is now well beyond its intended service life. Common failure mechanisms include:

- Lithium battery depletion: The onboard battery typically lasts 8–12 years. Once depleted, RAM contents (including runtime variables and temporary configurations) are lost on power cycle, causing program reset or boot failure.

- EPROM degradation: Older program storage modules suffer from charge leakage over decades, leading to checksum errors or corrupted logic during startup.

- Backplane connector corrosion: Oxidation on gold fingers or socket contacts causes intermittent communication or power delivery issues, often manifesting as random reboots.

- Capacitor aging: Electrolytic capacitors on the power regulation circuit degrade, introducing noise or voltage droop that destabilizes the CPU core.

Recommended preventive actions:

- Replace the internal lithium battery every 7–8 years, even if the system appears functional

- Perform annual cold-start tests to verify program reload integrity from EPROM

- Clean backplane connectors with contact enhancer and inspect for fretting corrosion

- Maintain at least one fully configured spare CPU in powered standby or climate-controlled storage

ABB SCYC51020 58052582G

Lifecycle Status and Migration Strategy

ABB officially ended support for the SATT 190 platform in the early 2000s, with the SCYC51020 classified as obsolete for over 15 years. No new units are available from the manufacturer, and authorized repair services have been discontinued. Continuing to operate this hardware carries substantial risk: spares are untraceable, firmware recovery tools are scarce, and engineering expertise is dwindling.

For facilities unable to fund immediate migration, viable interim strategies include:

- Securing tested, configured spares with full boot and I/O scan validation reports

- Implementing board-level refurbishment (battery replacement, capacitor rework, socket cleaning)

- Archiving original EPROM images and creating backup configuration sets

ABB’s recommended long-term migration path is to transition to the System 800xA platform. This requires full re-engineering of control logic, I/O rewiring or marshaling, and operator station replacement. Alternatively, third-party solutions such as soft-PLC emulation or I/O gateway retrofits can extend system life by 5–10 years while preserving field wiring. However, these approaches do not restore OEM support and must be evaluated against cyber-security and regulatory compliance requirements.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: