Description

Technical Specifications (For Spare Parts Verification)

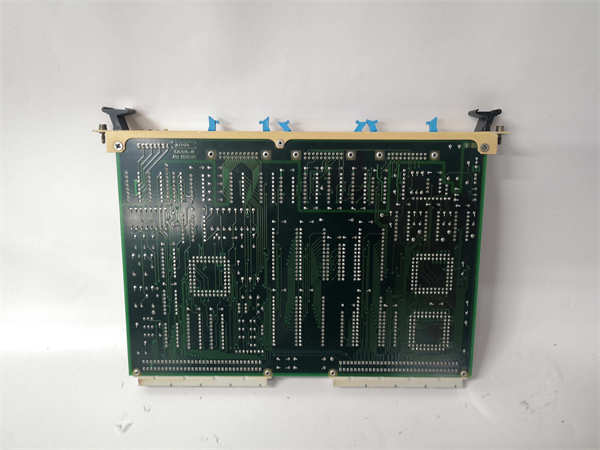

- Product Model: SCYC51010 58052515G

- Manufacturer: ABB

- System Platform: AC 800M within ABB 800xA DCS

- Module Type: Communication processor / fieldbus interface

- Supported Protocols: Profibus DP and Profibus PA (via coupler)

- Physical Interface: RS-485 (9-pin D-sub or terminal block, depending on carrier)

- Redundancy Support: Yes – supports redundant configuration in paired CI854/CI853 carriers

- Data Rate: Up to 12 Mbps (Profibus DP)

- Mounting: Pluggable module for PM86x/PM85x controller racks or remote I/O stations

- Diagnostic Features: LED indicators for module status, bus activity, and fault; detailed diagnostics via 800xA engineering station

- Power Consumption: Supplied via backplane; typical <5 W

System Role and Downtime Impact

The SCYC51010 is a critical communication enabler in legacy ABB 800xA systems, commonly deployed in power plants, refineries, and water treatment facilities. It resides either in the main controller rack or in remote I/O cabinets, translating between the internal AC 800M backplane protocol and external Profibus segments that connect dozens—sometimes hundreds—of field devices.

If this module fails or loses synchronization, all connected Profibus slaves become unreachable. The AC 800M controller typically logs a “communication fault” and may place affected control loops into manual or hold mode. In severe cases—such as loss of boiler feedwater pump status or turbine trip signals—the system could initiate a partial or full plant shutdown. Because the SCYC51010 often handles safety-related or regulatory-compliant measurements, its failure also impacts compliance reporting and alarm management. Replacement requires physical module swap and potential reinitialization of the Profibus master, usually during a planned outage window.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the SCYC51010 exhibits several age- and environment-related vulnerabilities:

- RS-485 transceiver degradation: The Profibus driver ICs are sensitive to repeated electrical overstress from ground loops or lightning-induced surges on field cables, leading to intermittent communication or complete port failure.

- Firmware corruption: Though rare, flash memory errors can occur due to power cycling without proper shutdown, causing the module to boot into a non-operational state.

- Backplane connector fatigue: Thermal expansion/contraction over years of operation can loosen the edge connector, resulting in intermittent contact and cyclic dropouts.

- Capacitor aging on internal power rails: Affects stability of the local 3.3V/5V logic supplies, potentially causing watchdog resets or erratic behavior under load.

A key limitation is the lack of hot-swap capability in early AC 800M systems—replacing the module typically requires powering down the entire controller or I/O station, increasing downtime exposure.

Preventive maintenance recommendations include:

- Installing Profibus surge protectors at cabinet entry points

- Verifying signal waveform integrity with an oscilloscope during major outages

- Monitoring 800xA diagnostic logs for “cyclic redundancy check (CRC) errors” or “slave timeout” trends

- Storing spares in ESD-safe, dry environments to preserve component integrity

ABB SCYC51010 58052515G

Lifecycle Status and Migration Strategy

ABB has officially discontinued the SCYC51010 as part of its transition to Ethernet-based field connectivity (e.g., PROFINET, EtherNet/IP) in modern 800xA releases. The module is no longer supported under standard service agreements, and factory repair is unavailable. Continued use carries significant operational risk due to diminishing spare availability and lack of cybersecurity updates.

Short-term mitigation should focus on:

- Securing a minimum of two fully tested spares with verified Profibus communication under load

- Documenting Profibus GSD files and network configuration to accelerate recovery

- Isolating critical Profibus segments onto dedicated SCYC51010 modules to limit fault propagation

The long-term migration path endorsed by ABB is to replace Profibus infrastructure with Ethernet-based alternatives:

- Upgrade to AC 800M controllers with built-in PROFINET interfaces (e.g., PM866AK01 + CI874)

- Replace Profibus field devices with PROFINET or HART-over-Ethernet equivalents

- Utilize ABB’s Network Manager in 800xA R6+ for seamless protocol integration

This transition eliminates dependency on obsolete serial fieldbuses, improves data bandwidth, enables remote diagnostics, and aligns the system with current IEC 62443 security practices. While requiring upfront engineering investment, it ensures operational continuity for the next decade or more.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: