Description

Key Technical Specifications (for Spare Verification)

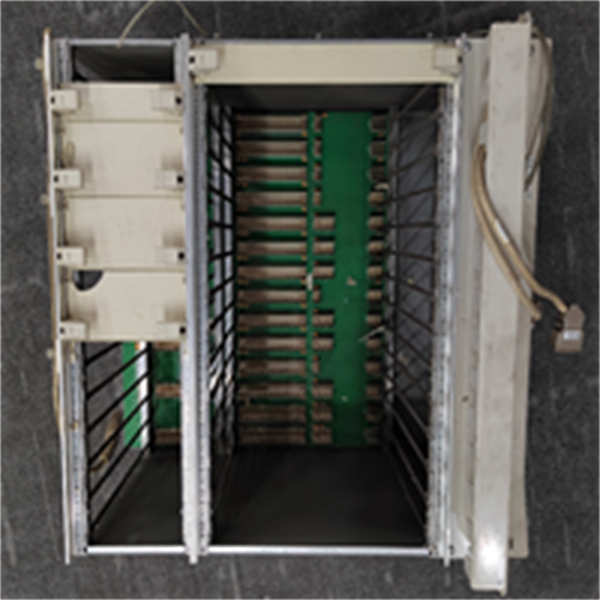

- Product Model: RF522

- Manufacturer: ABB

- Part Number: 3BSE000743R1

- Revision: R1

- System Family: ABB AC 800M / 800xA distributed control system

- Function: Dual redundant PROFIBUS DP master interface (RS-485 physical layer)

- Supported Data Rate: Up to 1.5 Mbps

- Max Slave Devices: 126 per bus (with repeaters)

- Redundancy Mode: Hot-standby (one active, one backup channel)

- Installation Slot: Requires dedicated slot in AC 800M I/O baseplate (e.g., TB840/TB850)

- Power Supply: +5 V and ±12 V from backplane

- Diagnostic Indicators: Per-channel LEDs for “RUN,” “TX/RX,” and “FAULT”

- Firmware Dependency: Must match version of connected CPU (e.g., PM864) and I/O modules

System Role and Downtime Impact

The RF522 serves as a critical communication gateway in legacy ABB 800xA systems, enabling the AC 800M controller to connect to PROFIBUS-based remote I/O racks—commonly used for motor control centers (MCCs), valve terminals, and drive panels in power, water, and industrial plants. Its redundant architecture ensures that a single cable or port failure does not disrupt field communication. However, if the RF522 module itself fails (e.g., due to internal component degradation), both communication channels may be lost, causing all downstream PROFIBUS slaves to go offline. In applications such as boiler feedwater control or wastewater treatment, this can lead to automatic safety trips, regulatory non-compliance, or extended unplanned downtime. Given its role in maintaining data continuity between control logic and field devices, the RF522 is a high-consequence single point of failure in aging installations.

Reliability Analysis and Common Failure Modes

Despite its robust design, the RF522 is now susceptible to age-related failures after 10–20 years of service. The most common issues include:

- PROFIBUS transceiver IC degradation, leading to intermittent communication errors or complete port failure

- Electrolytic capacitor aging on the internal DC-DC converter, causing voltage instability and module resets

- Corrosion or oxidation on the DIN 41612 backplane connector pins, resulting in poor contact and cyclic dropouts

- Firmware corruption during power cycling, especially if the module lacks clean shutdown procedures

The module’s reliance on precise timing for PROFIBUS token passing makes it sensitive to power quality; voltage sags or surges can trigger undervoltage lockout or latch-up conditions. Additionally, the absence of modern ESD protection on older revisions increases vulnerability during handling or cabinet maintenance.

Recommended preventive measures include:

- Monitoring 800xA system logs for “Fieldbus Communication Fault” or “RF522 Channel Switch” events

- Performing periodic thermal imaging of the I/O cabinet to detect abnormal heating on the module

- Ensuring clean, stable 24 VDC supply to the AC 800M power units to minimize backplane ripple

- Keeping spare modules powered in a test rack to prevent “shelf failure” due to capacitor drying

ABB RF522 3BSE000743R1

Lifecycle Status and Migration Strategy

ABB has officially discontinued the RF522 as part of the broader obsolescence of the AC 800M platform’s early-generation I/O modules. No new units are available through official channels, and technical documentation is increasingly difficult to access. Continued use carries significant operational risk, particularly in facilities without tested spares.

Short-term mitigation includes sourcing pre-tested, functionally verified units from specialized vendors who perform full protocol-level validation using PROFIBUS analyzers and live AC 800M test benches. Board-level repair is possible but constrained by obsolete semiconductor availability.

For long-term sustainability, ABB recommends migrating to the AC 800M High Availability (HA) architecture with modern communication modules such as the CI874 (PROFIBUS) or CI864 (Modbus TCP), which offer enhanced diagnostics, cybersecurity features, and compatibility with 800xA 6.0+. This migration typically involves:

- Replacing the I/O baseplate and communication modules

- Updating firmware and Control Builder M project libraries

- Revalidating redundancy switchover behavior

While requiring engineering effort, this path restores vendor support, improves network resilience, and aligns the system with current industrial communication standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: