Description

Technical Specifications (For Spare Part Verification)

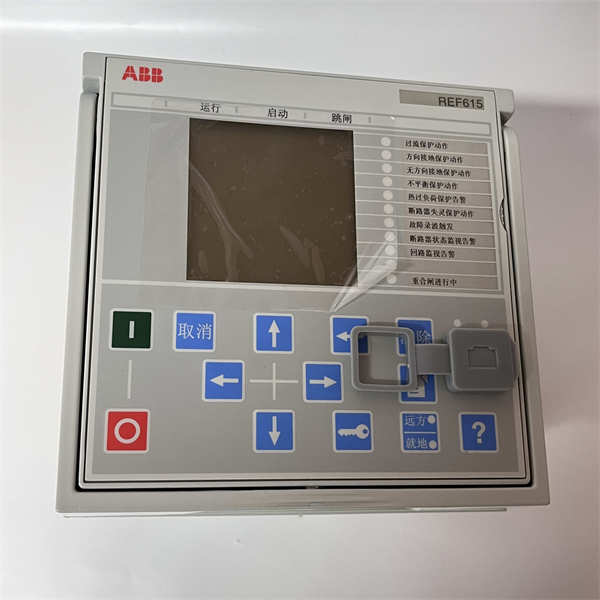

- Product Model: REF615C_E

- ABB Order Code: HCFEAEAGABC2BAA11E

- Manufacturer: ABB

- Product Line: Relion® REF615, Series C (Generation 1)

- Protection Functions: Phase overcurrent (50/51), earth-fault (50N/51N), breaker failure (50BF), thermal overload (49)

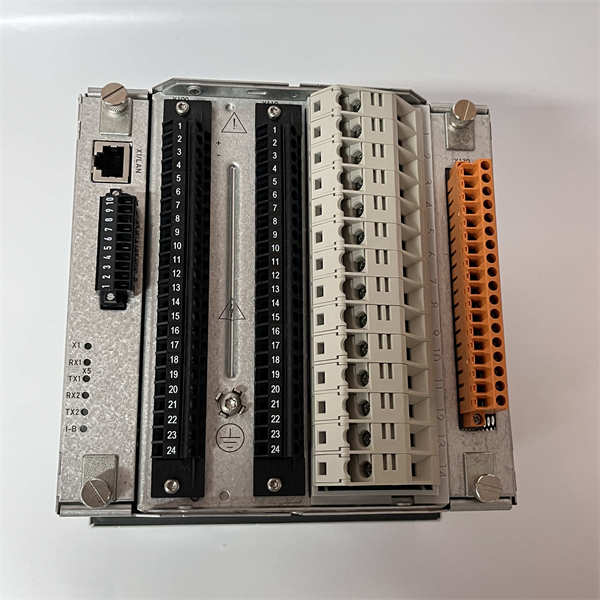

- Current Inputs: 3-phase + neutral (1 A or 5 A selectable)

- Voltage Inputs: Optional 3-phase + residual (for directional functions)

- Communication: IEC 61850 Edition 1 (MMS, GOOSE), Modbus RTU, DNP3 (via rear RS-485)

- Digital I/O: 8 binary inputs, 6 output contacts (2 high-speed for tripping)

- Front Interface: LCD display with navigation keypad

- Operating Temperature: –25°C to +55°C

- Firmware Baseline: Requires PCM600 v2.7 or earlier for configuration; not compatible with PCM600 v3+ without conversion

- Mechanical Form: Flush or surface mounting, 4U height (177 mm × 160 mm)

System Role and Downtime Impact

The ABB REF615C_E is a core protection device in medium-voltage switchgear panels, commonly deployed in industrial plants, utilities, and commercial facilities. It continuously monitors feeder current and voltage to detect faults and initiate breaker tripping within milliseconds. In motor protection applications, it also prevents thermal damage from overload conditions.

If the relay fails or loses communication, the protected asset operates without automatic fault clearance. This creates a severe safety and equipment risk: a downstream short circuit could escalate into busbar damage, fire, or arc flash incident. Even partial failure—such as loss of earth-fault sensitivity—may allow ground faults to persist undetected, violating regulatory standards (e.g., NFPA 70E). In IEC 61850 systems, loss of GOOSE messaging can disable interlocking or auto-transfer schemes, compromising system resilience.

Reliability Analysis and Common Failure Modes

Although designed for 15–20 years of service, many REF615C_E units are now operating beyond their intended lifecycle. Common failure patterns include:

- Internal power supply capacitor aging: Electrolytic capacitors on the auxiliary power board degrade, causing intermittent resets or complete shutdown during voltage sags.

- Display and keypad wear: The front-panel LCD and membrane keypad suffer from mechanical fatigue, leading to unresponsive buttons or unreadable screens—hindering local operation during outages.

- Communication processor instability: The legacy IEC 61850 stack (Edition 1) is prone to MMS session drops under network stress, especially when coexisting with newer IEC 61850 Ed2 devices.

A key vulnerability is the lack of secure firmware updates—making older units susceptible to cybersecurity gaps if connected to modern SCADA networks. As preventive maintenance, users should:

- Perform annual primary injection testing to verify trip accuracy and timing.

- Back up relay settings using PCM600 v2.7 while tools are still available.

- Inspect terminal blocks for overheating signs and ensure clean, torque-compliant wiring on CT/VT circuits.

ABB REF615C_E HCFEAEAGABC2BAA11E

Lifecycle Status and Migration Strategy

ABB has officially discontinued the REF615C_E (Series C, Generation 1). It is no longer listed in current catalogs, and technical support is restricted. The recommended replacement is the REF615 V3 (e.g., order code HCFEAEAGABC2BAB11E), which supports IEC 61850 Edition 2, enhanced cybersecurity (IEC 62351), and improved hardware reliability.

However, migration is not drop-in:

- The V3 uses a different hardware platform and requires re-engineering of IEC 61850 SCL files.

- PCM600 project conversion is possible but may lose custom logic or HMI mappings.

- Physical dimensions differ slightly—panel cutouts may need modification.

As a temporary measure, facilities can:

- Secure tested spares with verified firmware and configuration backups.

- Isolate the relay’s communication port via a managed switch with strict ACLs to reduce cyber exposure.

Long-term, a full protection system audit is advised to align with modern standards (e.g., IEC 61850-6 SCL engineering, cybersecurity hardening). Given the critical safety role of protection relays, continued use of obsolete models should be justified through formal risk assessment and mitigation planning.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: