Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: PXAH401

- Manufacturer: ABB

- System Family: AC 800M / S800 I/O System

- Function: I/O Communication Adapter (ModuleBus to S800 backplane)

- Supported I/O Modules: Full S800 series (AI, AO, DI, DO, etc.)

- Communication Protocol: ABB proprietary ModuleBus (serial, deterministic)

- Redundancy Support: Yes – used in redundant AC 800M configurations with dual PXAH401 units

- Power Consumption: Approx. 3.5 W

- Mounting: DIN rail in S800 I/O subrack (e.g., TK801A)

- Diagnostic LEDs: RUN, ERROR, I/O BUS status indicators

- Firmware Dependency: Requires matching firmware version with AC 800M CPU (typically PM86x series)

System Role and Downtime Impact

The PXAH401 is a foundational component in ABB’s AC 800M distributed control architecture, acting as the sole communication gateway between the central controller and a local S800 I/O station. It resides in every remote I/O cabinet and enables real-time data exchange over the ModuleBus. If a PXAH401 fails—due to power surge, firmware corruption, or internal component degradation—the entire I/O rack it serves becomes unreachable. In process industries like oil & gas, power generation, or pulp & paper, this can result in loss of critical sensor readings (e.g., pressure, temperature) or actuator control (e.g., valve positioning), potentially triggering a plant-wide safety shutdown or forcing manual operation under degraded conditions. In redundant systems, a single PXAH401 failure may not cause immediate downtime but eliminates fault tolerance, leaving the system vulnerable to a second failure.

Reliability Analysis and Common Failure Modes

Despite its industrial-grade design, the PXAH401 exhibits age-related vulnerabilities after 15–20 years of service. The most common failure mode is firmware corruption during unexpected power cycles, especially if backup capacitors degrade. This manifests as a solid ERROR LED and inability to synchronize with the CPU. Second, electrolytic capacitors on the internal power regulation circuit dry out over time, leading to voltage instability and intermittent communication drops. Third, ModuleBus transceiver ICs are sensitive to ground loops or EMI in poorly shielded installations, causing data errors that accumulate until the link drops.

A key design limitation is its lack of field-upgradable firmware via standard tools—recovery often requires specialized ABB service equipment or module replacement. Additionally, the unit has no built-in watchdog for bus traffic, so silent failures can go undetected until a process deviation occurs.

For preventive maintenance, regularly check diagnostic LEDs during routine rounds. Monitor I/O scan times in the control system—if latency increases, it may indicate early bus degradation. Ensure proper grounding of the I/O subrack and use shielded ModuleBus cables with 360° termination. During planned outages, inspect for bulging capacitors or burnt components near the power input. Keep a known-good spare powered periodically to maintain capacitor health.

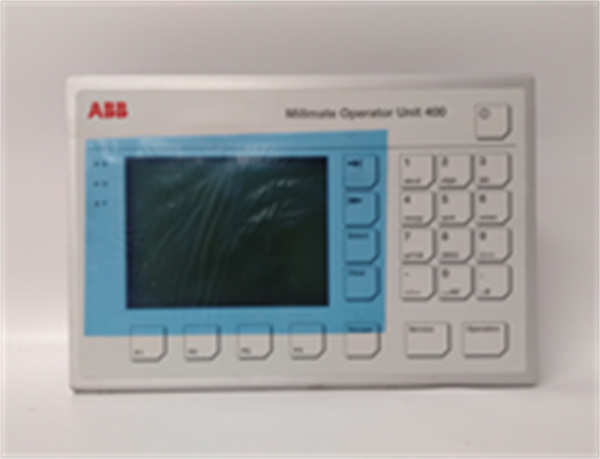

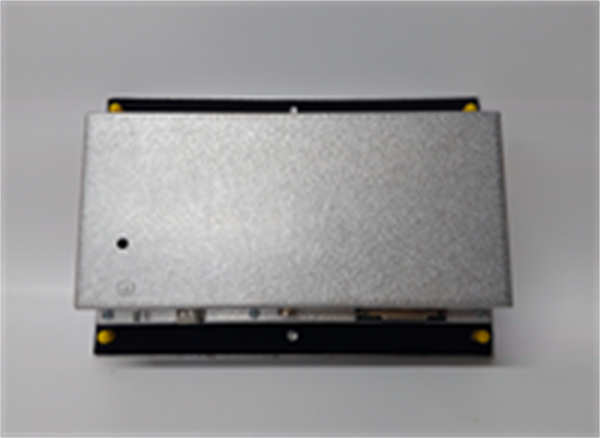

ABB PXAH401

Lifecycle Status and Migration Strategy

ABB officially discontinued the PXAH401 as part of the broader phase-out of the AC 800M legacy platform, with end-of-life announcements issued years ago. No new units are produced, and ABB no longer provides repair services or firmware updates. Continued operation relies entirely on existing inventory, which is dwindling and increasingly expensive.

As a short-term measure, source tested and certified refurbished units from reputable suppliers who perform full functional validation. Maintain at least one spare per critical I/O station and document its serial number and test report.

For long-term sustainability, ABB’s strategic migration path is to the AC 800M Extended (PM866A/PM867A CPUs) with S800 I/O using the newer PXAM401 or PXAR401 adapters, or—more future-proof—to the Ability™ System 800xA with AC 900F controllers and S900 I/O. However, a direct hardware swap is not possible. Migration typically involves:

- Replacing the entire I/O subrack with S900 or updated S800 components

- Upgrading the controller to a supported AC 800M CPU or AC 900F

- Re-engineering I/O wiring (terminal blocks may differ)

- Revalidating all control logic and HMI graphics

Given the complexity, many users adopt a “managed obsolescence” approach: extend life through rigorous spares management while planning a phased modernization during major turnarounds. Early engagement with ABB or certified system integrators is essential to define a technically and economically viable path forward.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: