Description

Key Technical Specifications (For Spare Part Verification)

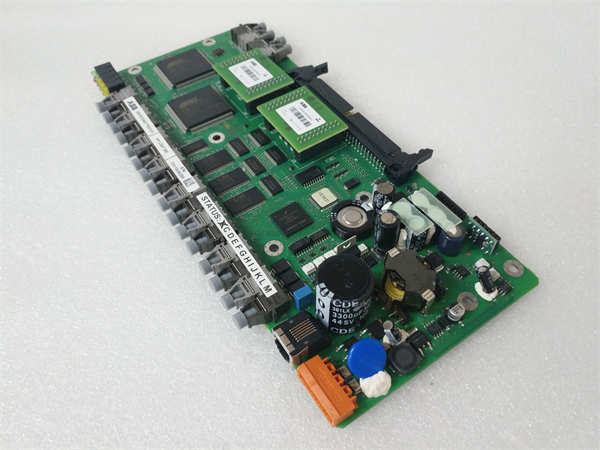

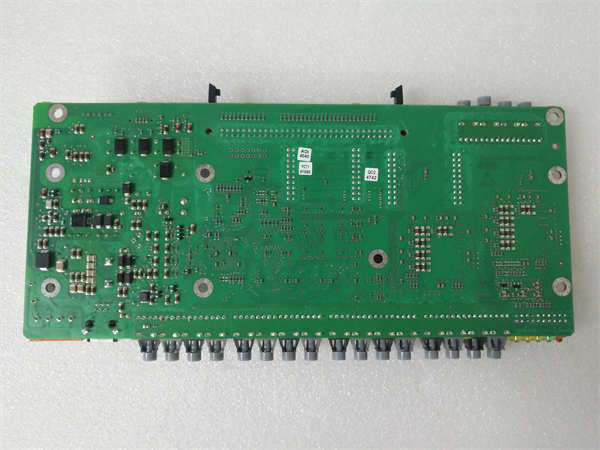

- Product Model: PPC907BE

- ABB Order Code: 3BHE024577R0101

- System Family: ABB AC 800M (used with PM86x/CI87x controllers)

- Input Voltage: 88–132 V AC or 100–150 V DC (universal input range)

- Output: 24 V DC, 7 A continuous (168 W); peak up to 10 A for short durations

- Redundancy Support: Designed for parallel operation with a second PPC907BE via redundancy bus connector (backplane or external cabling)

- Efficiency: >85% at full load

- Protections: Over-voltage, over-current, short-circuit, and thermal shutdown

- Status Indication: Front-panel LEDs for OK, FAULT, and REDUNDANCY ACTIVE

- Mounting: DIN rail or chassis-mounted in AC 800M cabinet

- Cooling: Convection-cooled (no fan)

- Dimensions: Standard 80 mm width (fits ABB 800xA rack layout)

- Certifications: CE, UL, cUL, IEC 61010

System Role and Downtime Impact

The PPC907BE is a foundational component of AC 800M reliability architecture. In redundant configurations (two PPC907BE units), the system continues operating if one fails—but in cost-optimized or older installations, only a single unit may be deployed. In such cases, any power supply failure results in immediate loss of controller operation, causing:

- Tripping of safety interlocks

- Loss of motor control, valve positioning, and analog regulation

- Disruption of communication with SCADA, historians, and operator stations

Recovery requires physical replacement and verification of output stability before re-energizing the controller—processes that can take hours in remote or hazardous locations. Moreover, mismatched or counterfeit PSUs can introduce voltage ripple that damages sensitive CPU modules, compounding risk.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the PPC907BE is vulnerable to long-term stress after 10–15 years of service:

- Electrolytic capacitor drying/leakage: Causes output voltage droop, ripple increase, or thermal shutdown

- Fanless thermal stress: Repeated heating/cooling cycles fatigue solder joints on high-current paths

- Input rectifier diode degradation: Leads to intermittent startup or brownout behavior

- Redundancy bus connector corrosion: Prevents proper load sharing in dual-PSU setups

- LED/display driver failure: Masks fault conditions, delaying maintenance response

Environmental factors like high ambient temperature (>50°C), dust accumulation, and unstable plant power quality accelerate these issues. Recommended preventive actions include:

- Annual infrared thermography of PSU under load

- Measurement of output ripple (<100 mVpp recommended)

- Verification of redundancy switchover via simulated failure test

- Storage of spares in dry, temperature-controlled environments

ABB PPC907BE 3BHE024577R0101

Lifecycle Status and Migration Strategy

ABB has discontinued the PPC907BE (3BHE024577R0101) and replaced it with updated models such as the PPC907AE (improved efficiency) and PPC911 (higher power, enhanced diagnostics). However, even these successors are being phased out in favor of modular, cyber-secure power architectures within the Ability™ System 800xA ecosystem.

Short-term mitigation:

- Maintain at least one tested spare with verified output and redundancy function

- Avoid mixing PSU revisions (e.g., BE with AE) in redundant pairs

- Implement UPS or buffered DC distribution upstream

Long-term migration path:

- Upgrade to PPC911 or compatible ABB-recommended PSU (if staying within AC 800M)

- Transition to System 800xA with AC 900F controllers, which use standardized, serviceable power modules with predictive health monitoring

- Adopt intelligent DC power distribution units (PDUs) with remote current/voltage telemetry for early anomaly detection

Migration not only addresses obsolescence but also enhances system resilience through better diagnostics, thermal management, and integration with ABB’s digital asset performance tools—ensuring continued operational integrity in critical process industries.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: