Description

Key Technical Specifications (For Spare Part Verification)

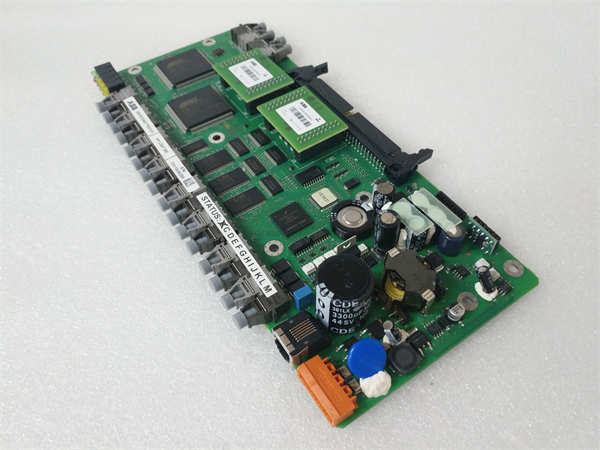

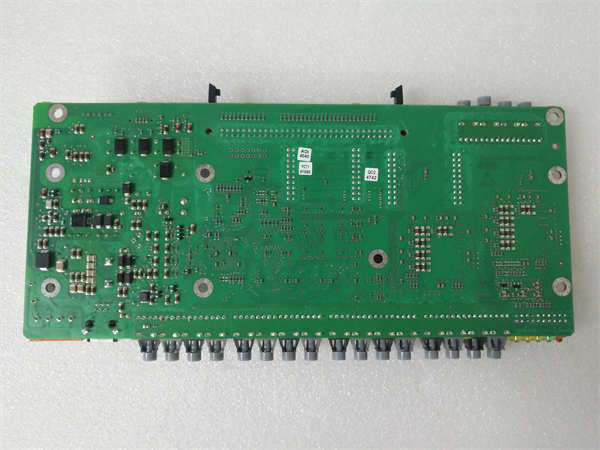

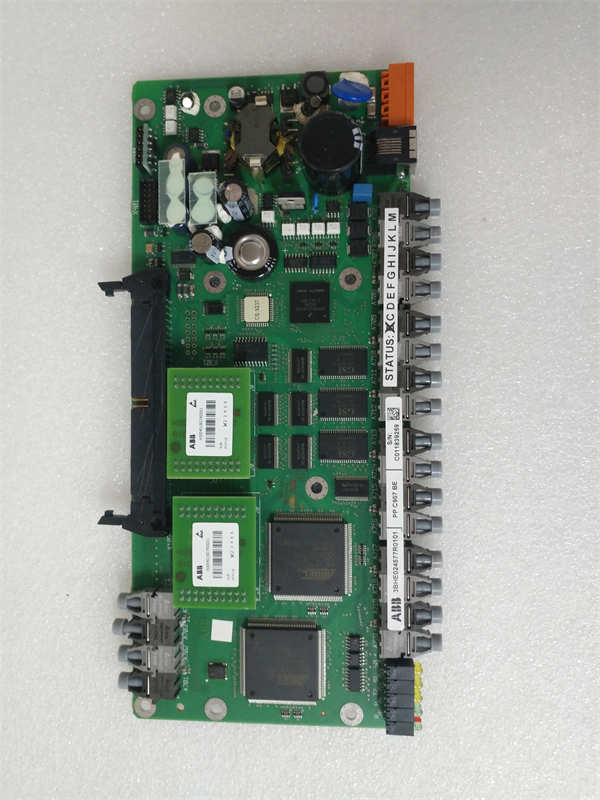

- Product Model: PPC907BE

- ABB Order Code: 3BHE024577R0101

- Manufacturer: ABB

- System Family: AC 800M (part of System 800xA architecture)

- Function: Main controller CPU with real-time execution engine for control applications

- Processor: PowerPC-based embedded processor (clock speed ~266 MHz)

- Memory: Integrated DRAM and flash memory for program and configuration storage

- Communication Interfaces: Dual redundant CI854 or CI864 fieldbus interfaces (Profibus DP, Modbus RTU); optional Ethernet for engineering access

- Redundancy Support: Hot-standby capable when paired with a second PPC907BE and synchronization module

- Mounting: DIN rail or rack-mounted in AC 800M cabinet with backplane connection

- Firmware Dependency: Tightly bound to specific versions of Control Builder M; mismatched firmware prevents project download or causes runtime faults

ABB PPC907BE 3BHE024577R0101

System Role and Downtime Impact

The PPC907BE is the computational heart of the ABB AC 800M controller, widely deployed in oil & gas, power generation, mining, and chemical facilities as part of the System 800xA integrated control platform. It runs all regulatory control loops (e.g., PID, cascade), sequence logic, and alarm management for its assigned process area—often managing hundreds of I/O points across multiple remote racks.

In non-redundant configurations—which are common in mid-sized or older installations—a single PPC907BE failure results in an immediate halt to all automated functions in that control domain. This can trigger emergency shutdowns (ESD), loss of pressure/temperature control, or violation of environmental permits. Even in redundant setups, degraded health of one unit increases exposure during maintenance or grid disturbances. Recovery time is directly tied to spare availability, with outages potentially extending beyond 72 hours if a verified replacement cannot be sourced quickly.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, units in service beyond 10–15 years show predictable aging effects:

- Flash memory corruption: Repeated power cycles or electrostatic discharge can corrupt the boot loader or application image, causing “No Program” or “Fatal Error” states.

- Onboard battery depletion: The internal lithium battery (used to maintain real-time clock and volatile memory during power loss) typically fails after 8–12 years, leading to configuration resets or boot loops.

- Backplane connector oxidation: Thermal cycling induces micro-fretting in edge connectors, resulting in intermittent communication with I/O modules or redundant partner.

- Capacitor aging: Electrolytic capacitors in the local power regulation circuit dry out, increasing output ripple and causing unexpected reboots under load.

- Firmware/project version lock: Replacement requires exact alignment between hardware revision, firmware, and Control Builder M project version—often unattainable without original engineering archives.

Recommended preventive actions:

- Perform annual backup of controller application and configuration using Control Builder M

- Replace the internal backup battery during planned outages (if accessible)

- Monitor system logs for “Watchdog Reset” or “I/O Bus Fault” warnings

- Maintain at least two tested spares in climate-controlled, ESD-safe storage

ABB PPC907BE 3BHE024577R0101

Lifecycle Status and Migration Strategy

ABB has discontinued the PPC907BE in favor of newer AC 800M CPUs such as the PM864, PM866, and ultimately the AC 800M High Performance series (e.g., PM874). While ABB still supports the AC 800M platform broadly, this specific module is no longer repairable or available new.

Short-term mitigation options include:

- Sourcing verified-used units from decommissioned sites or ABB-certified surplus vendors

- Engaging third-party specialists for board-level repair or firmware recovery

- Implementing external watchdog systems to detect early signs of CPU instability

The strategic path forward is migration to a current-generation controller within the System 800xA ecosystem:

- Upgrade to PM866AK01 or PM874 for enhanced performance, cybersecurity (IEC 62443), and extended lifecycle

- Retain existing I/O modules where possible via compatible communication modules (e.g., CI874)

- Reuse up to 80% of existing control logic through Control Builder M project conversion tools

- Recommission critical loops and validate cybersecurity posture post-upgrade

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: