Description

Key Technical Specifications (For Spare Parts Verification)

- Product Models: PPA322B, HIEE300016R2, HIEE400235R1

- Manufacturer: ABB

- Associated System: ABB AC 800M within System 800xA architecture

- PPA322B Output: 24 VDC / 10 A continuous (per unit), with current sharing for redundancy

- Input Voltage: 85–265 VAC or 100–300 VDC (wide-range universal input)

- HIEE300016R2 Function: Redundant mounting base enabling hot-swap and load-sharing between two PPA322B units

- HIEE400235R1 Function: Backplane power distribution adapter that routes 24 VDC from the base to the CI854/CI864 communication modules and I/O carriers

- Mechanical Format: DIN rail mounted, integrated into AC 800M local I/O rack

- Status Indication: LED indicators for “Power OK”, “Fuse OK”, and “Redundancy Active”

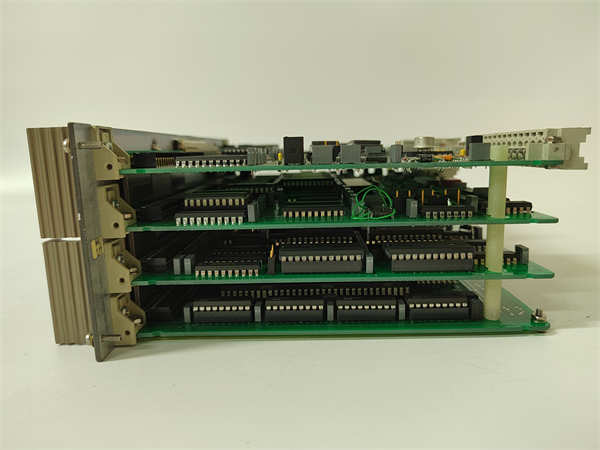

- Physical Identification: PPA322B labeled on front; HIEE300016R2 is green base with dual slots; HIEE400235R1 is a small PCB adapter behind the base

System Role and Downtime Impact

The PPA322B power supply—installed in the HIEE300016R2 redundant base and connected via HIEE400235R1—forms the electrical backbone of an AC 800M local I/O station. This assembly powers the communication module (e.g., CI854), all I/O modules, and their terminal bases. In a redundant configuration, loss of one PPA322B is tolerated, but failure of both—or failure of the base/backplane interface—results in total loss of communication and I/O scanning for that station. In process automation environments such as refineries or power plants, this can disable dozens of control loops, safety interlocks, or motor commands, potentially triggering a partial or full plant trip. Unlike field instruments, this component is not bypassable; its failure directly collapses the local control node.

Reliability Analysis and Common Failure Modes

Although designed for industrial use, these components exhibit predictable aging patterns. The PPA322B commonly fails due to electrolytic capacitor degradation, especially in high-ambient-temperature cabinets, leading to output voltage droop, ripple increase, or complete shutdown. Fanless design limits heat dissipation, accelerating component stress. The HIEE300016R2 base suffers from connector pin fatigue and corrosion on power bus contacts, which can disrupt current sharing and cause unexpected switchover or single-point failure. The HIEE400235R1 adapter, being a small PCB, is vulnerable to solder joint cracking from thermal cycling. Preventive maintenance should include: infrared thermography to detect hot spots, periodic verification of output voltage under load, visual inspection of base contacts for oxidation, and ensuring cabinet cooling is functional. Never operate without redundancy if the system supports it.

ABB PPA322B HIEE300016R2 HIEE400235R1

Lifecycle Status and Migration Strategy

ABB has formally discontinued the PPA322B family and associated hardware. No direct replacement exists under new order codes. Continuing to operate with these components carries escalating risk: genuine spares are scarce, used units may have hidden wear, and repair services are limited to third parties without OEM certification. As a temporary measure, facilities should secure a minimum of two fully tested redundant sets per critical station and implement enhanced monitoring (e.g., DC voltage logging). For long-term sustainability, ABB recommends migrating to the AC 800M PM86x series or AC 500 platform, which use modern power supplies like PPC320 or TB550/TB551 bases with improved efficiency and diagnostics. This migration requires re-engineering the I/O station layout, updating Control Builder M projects, and potentially rewiring field connections—but it restores access to full lifecycle support, cybersecurity updates, and spare parts availability. Planning should begin immediately, as lead times for transitional engineering can exceed 12 months.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: